Partner with advanced engineering and micromanufacturing experts to bring your medical device concepts to life. At the forefront of medical manufacturing technology, we excel in solving complex manufacturing problems for components and assemblies that enable continuous breakthroughs for medical and life science technologies. Leading medical innovators rely on Resonetics for seamless collaboration and a rapid pace to help quickly develop new technologies that advance treatment options and improve patient lives.

Manufacturing Solutions

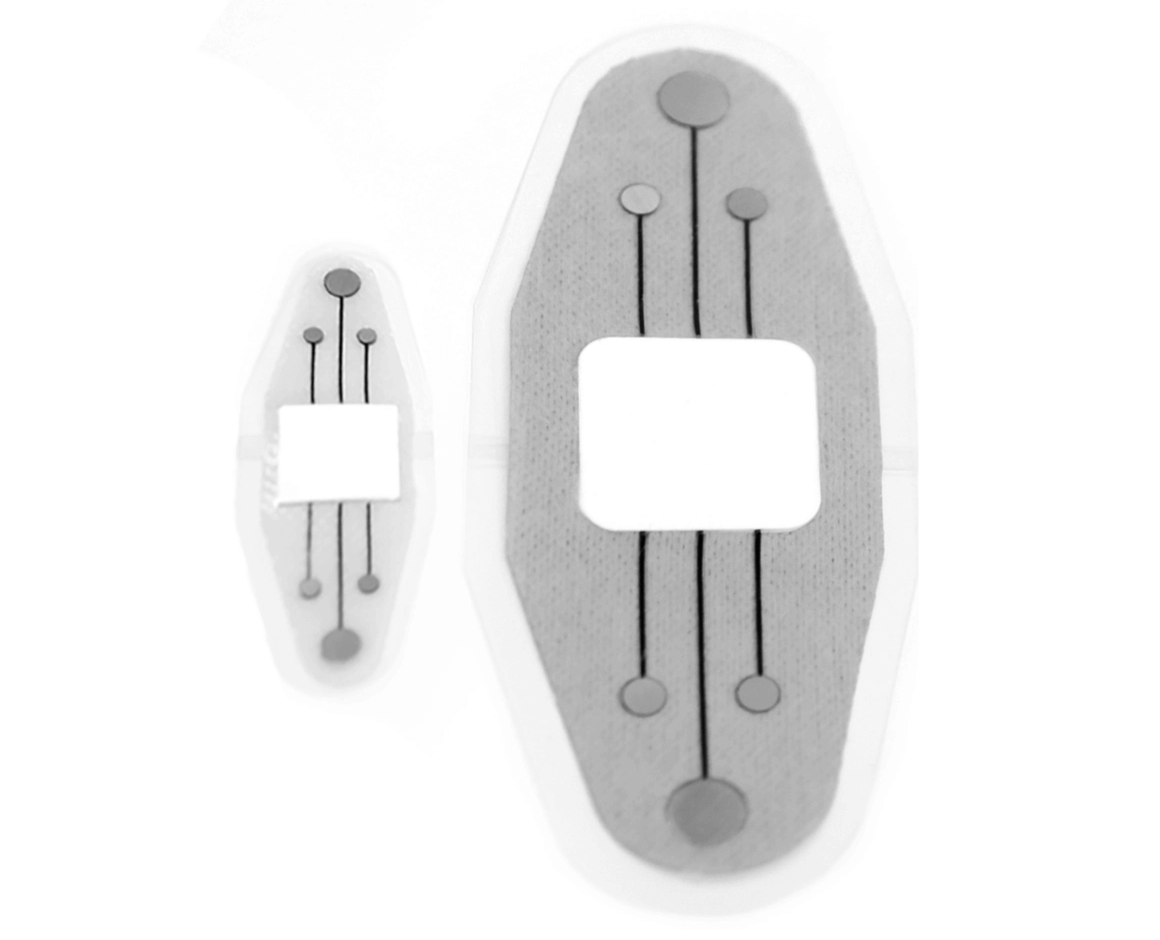

Microfluidic Laminates

Resonetics is a market leader in microfluidic laminate manufacturing used to make point-of-care diagnostics and lab-on-a-chip devices. Our unique manufacturing capabilities, process expertise, and automated processing equipment allow us to help you quickly develop and launch new microfluidic products.

Custom Laser Systems

For more than 30 years, Resonetics has designed, manufactured, and serviced laser micromachining workstations to solve complex manufacturing challenges in medtech and life sciences products.

Laser Processing

We are the leader in laser processing for complex medical devices, components, and implants. Our engineers have a deep process knowledge, and we custom build our own laser processing systems to provide the best manufacturing solution for each application. Our core laser processing capabilities include cutting, welding, drilling, ablating, and perforation.

Metal Fabrication

Our metal fabrication and machining capabilities, technical experience, and state-of-the-art equipment enable the production of custom small-scale parts and components with the precision and functionality your projects demand.

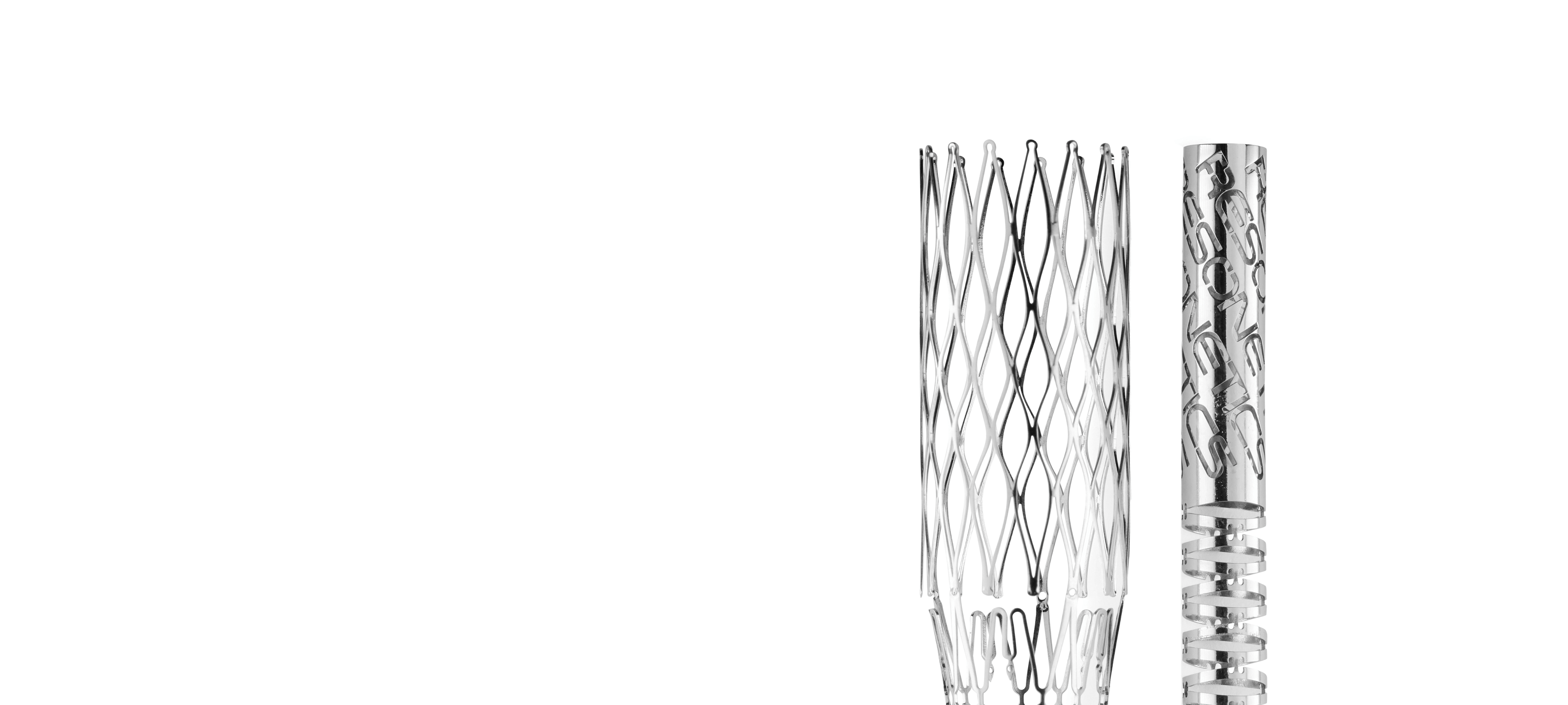

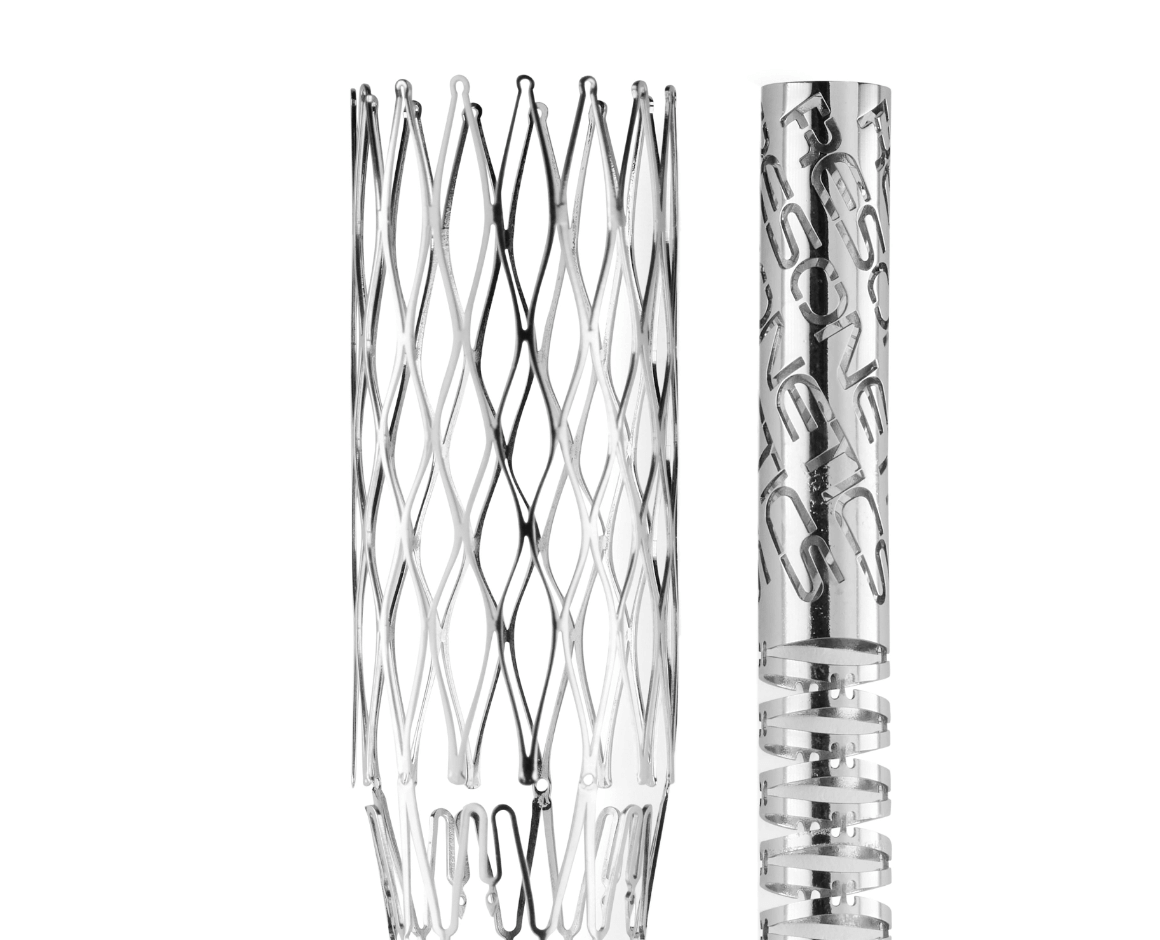

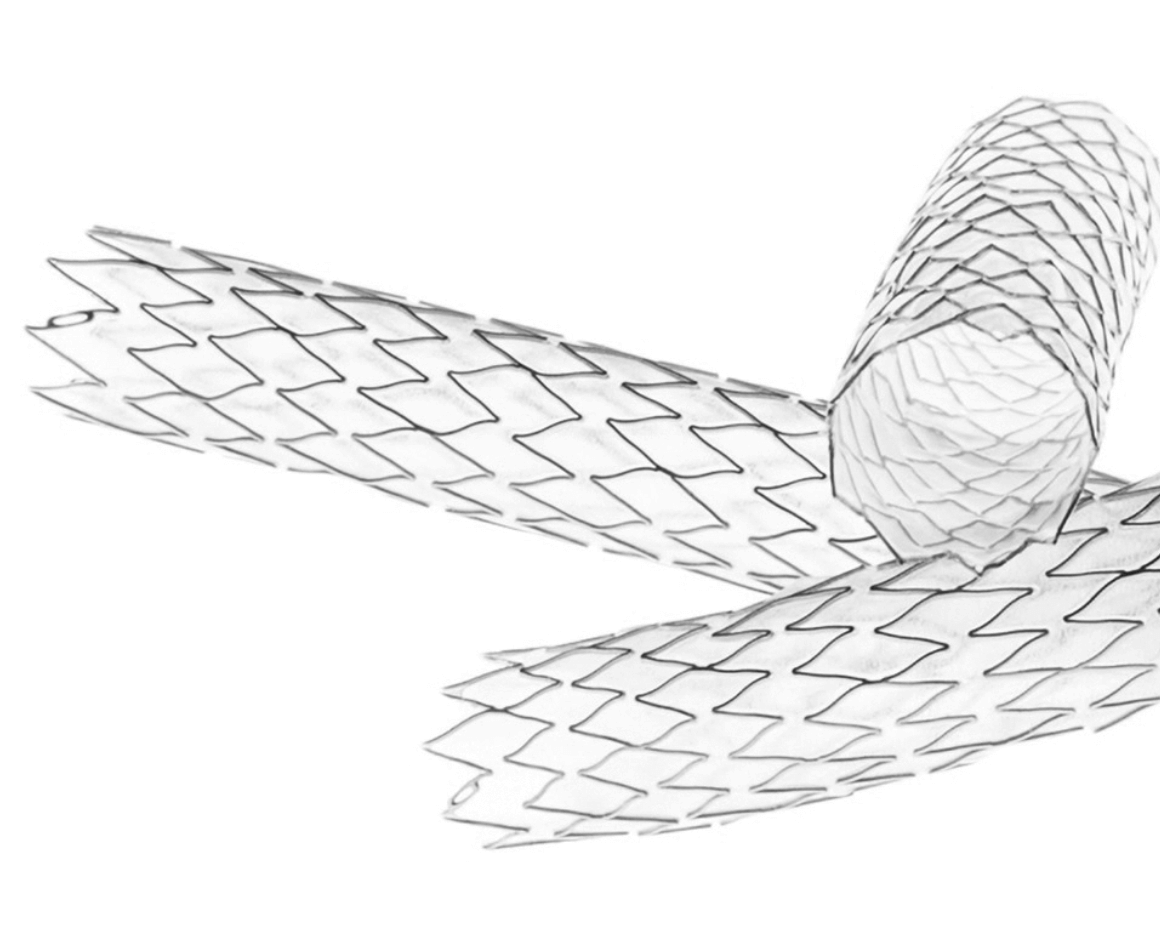

Nitinol Processing

Nitinol (Nickel Titanium) is a revolutionary alloy with a world of possibilities. Resonetics leads the industry in processing this material through a unique combination of traditional processes and innovative, modern manufacturing methods.

Coatings & Coverings

Our advanced Medibrane polymer coatings and coverings capabilities offer improved performance with our proprietary adhesion technology. This technology activates the surface and improves the bond between metals and polymers. Our engineers can help you choose the right process and materials to meet the needs of your application.

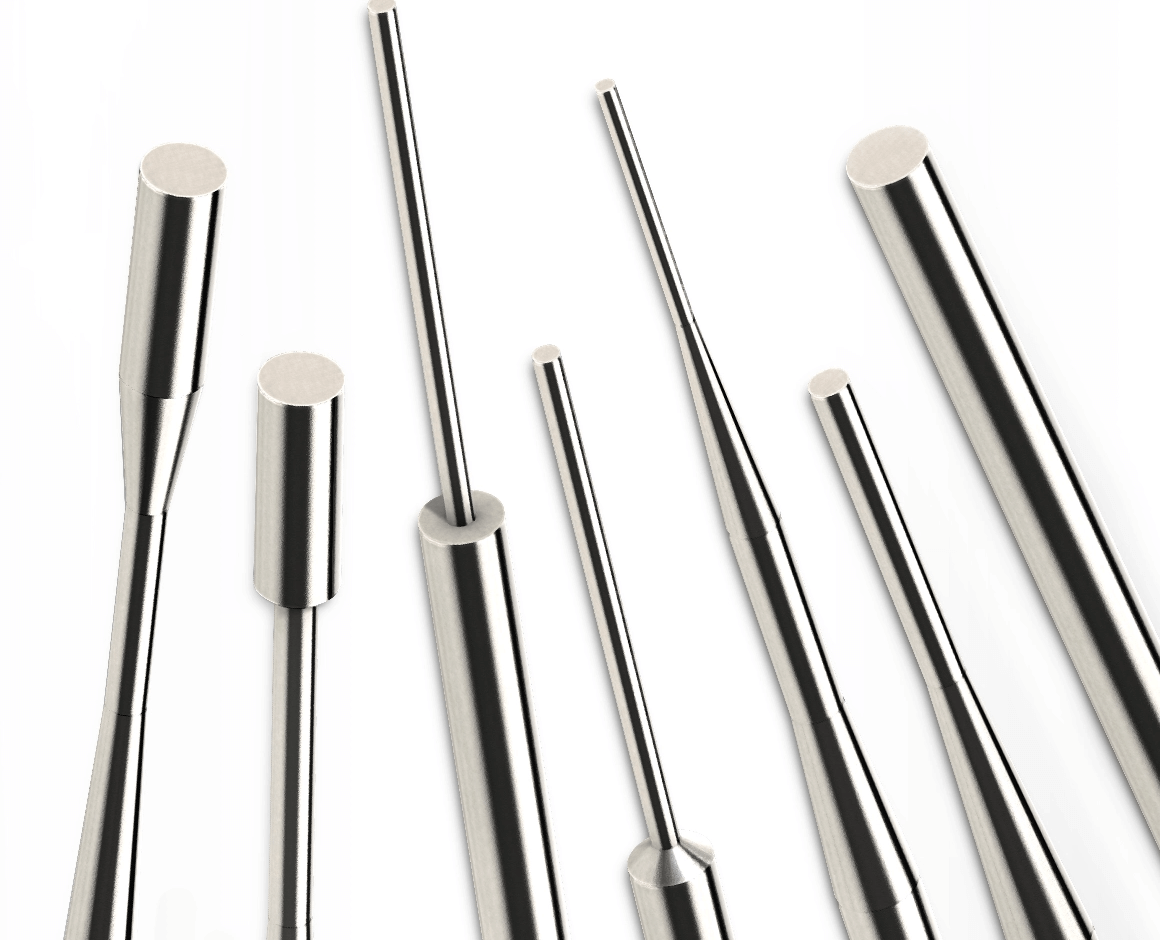

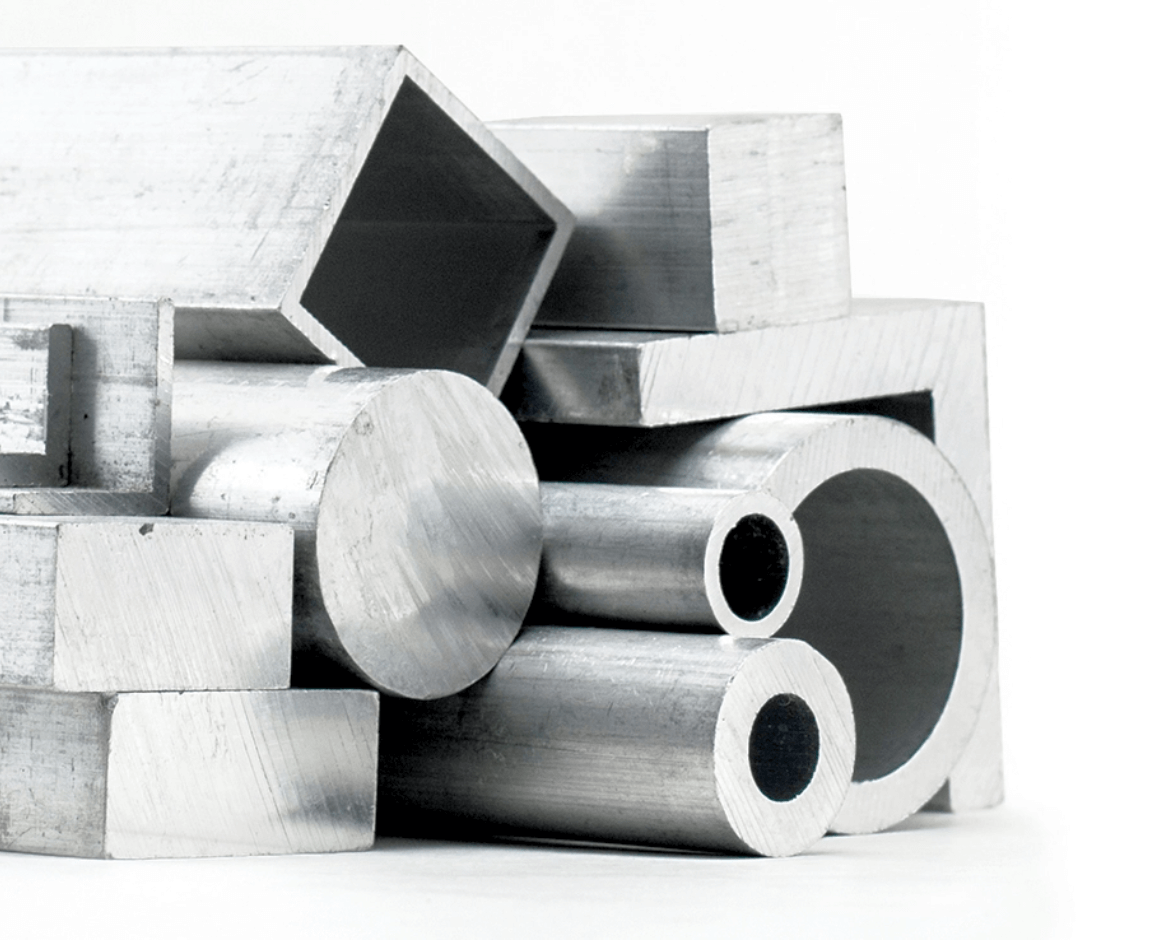

Raw Material

Critical medical devices and implants require the highest quality raw material. We produce different types of raw materials for medtech applications, including thin-wall hypotubing, precious metal marker bands, and nitinol wire.

Value-Add Services

To further support our customers engaged with AGILE Product Development and other manufacturing solutions at Resonetics, we offer value-add services to streamline the medical device production supply chain.