We have developed proprietary processes that use high-speed lasers to selectively remove material from a substrate or 3D machine micro-scale components and devices from a solid metal material. These processes minimize heat input, reduce thermal damage, and can be done in one setup, reducing handling and cost. To achieve a more consistent material removal during wire stripping, we created our patented ASSURE Endpoint Detection process. Our MICRABLATE 3D Laser Machining process allows us to produce micro-scale parts and features that are impossible with any other manufacturing method. Our Lightspeed Lab process experts can help you take advantage of these advanced technologies with industry-leading prototype solutions, design feedback, and manufacturing process development. When your design is ready for production, we have a standardized system to validate the process, experience, and resources to scale as needed.

Laser Ablating

MICRABLATE 3D Laser Machining

Our MICRABLATE 3D Laser Machining process uses a highspeed laser to selectively remove material from a solid material to produce cutting-edge micro-scale components that are too small for other processing methods. We design and build our own laser ablation systems that are fully automated, including in-process inspection and minimizing material handling.

ASSURE Endpoint Detection

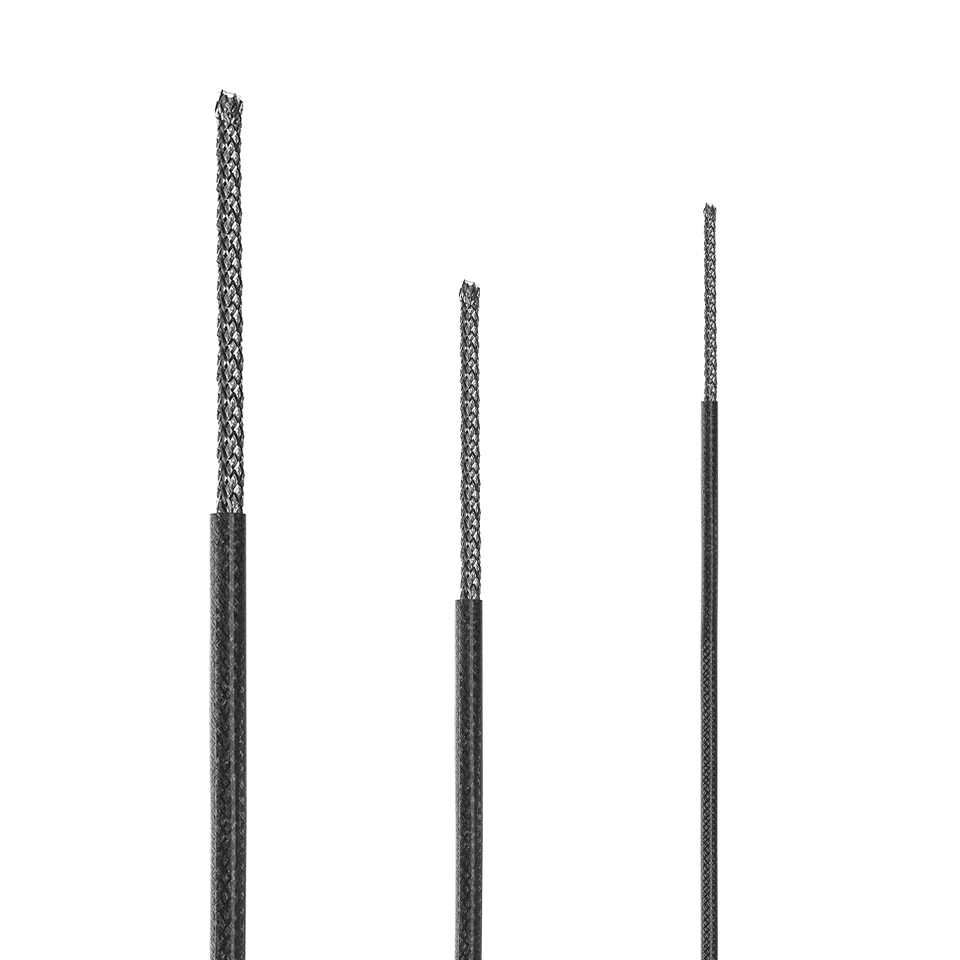

ASSURE Endpoint Detection is a patented process we developed for our custom reel-to-reel wire ablation platform. It solves a common challenge of removing multi-layer eccentric coatings from wires by using a closed-loop detector to adjust the laser ablation process in real-time, accommodating local inconsistencies in coating thickness. This allows our process to achieve a more consistent material removal, resulting in a more consistent finished component.

Laser Ablating Applications

Laser ablating removes material for micromachining and fabrication applications such as:

- 3D micro components

- Wire coating stripping

- Radiopaque marker bands

- Single-lumen catheters

- Multi-lumen catheters

- Tip shaping of catheters

- Electrode coating removal

- Balloon surface texturing

Medical Device & Technology Markets We Serve

Innovators developing groundbreaking medical devices rely on our laser ablating capabilities to create new technologies that advance treatment options and improve patient lives. Market applications for components and devices produced with our laser ablation processes include:

- Neurovascular

- Ophthalmic

- Structural heart

- Diabetes

- Electrophysiology

- Peripheral vascular

- Minimally invasive surgery

- Neuromodulation

- Sports medicine