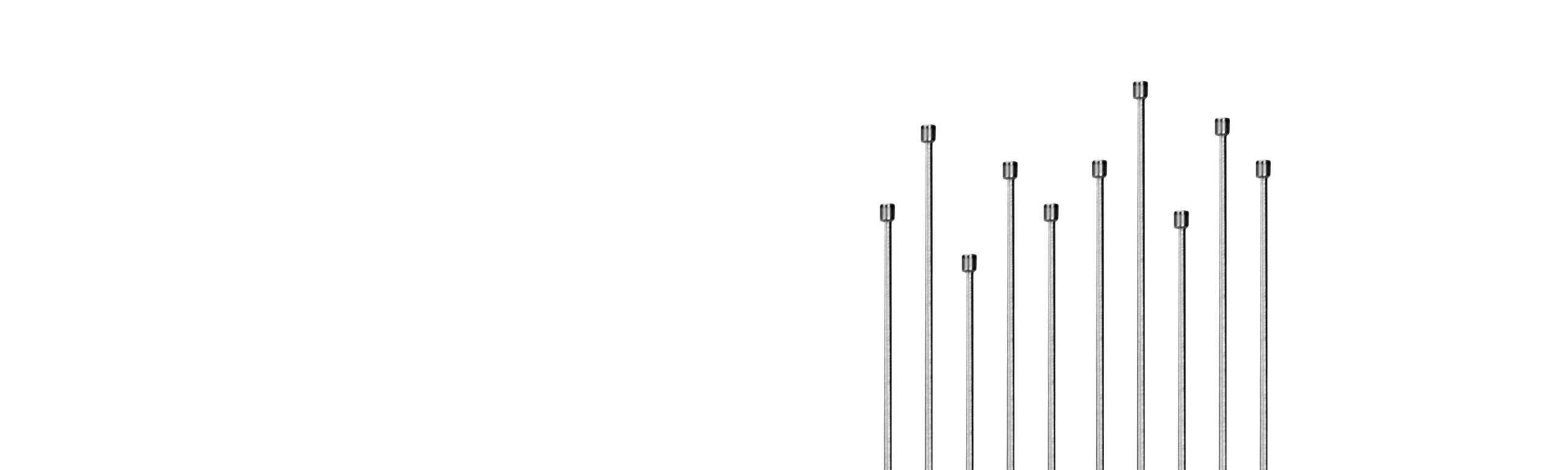

We use our proprietary centerless grinding equipment to put features and profiles in metal wire for medical applications such as delivery systems for minimally invasive surgery and mandrels.

With unparalleled machine design, automation experience, and over 100 unique grinding systems, our engineers and technicians produce more than 6 million ground components annually. To support a new project, we have dedicated resources with our Lightspeed Lab to help you during the development cycle with quick prototypes and design feedback related to manufacturability. When the design is finalized, we have a standardized system to validate the manufacturing process and production resources in the USA and Costa Rica to help you scale quickly to high volumes.