Metal Fabrication

We are experts in solving complex manufacturing challenges and have broad expertise in many different manufacturing methods for metal fabrication. By combining these with our other capabilities, we can develop the best manufacturing process for your part and support your needs from prototyping to high-volume production. Each of our different capabilities is supported by experienced process experts, state-of-the-art manufacturing equipment, and a proven quality system.

Centerless Grinding

We use our proprietary centerless grinding equipment to put features and profiles in metal wire and tubing for medical applications such as delivery systems for minimally invasive surgery and mandrels.

CNC Machining

Our experienced engineers and machinists can develop the best manufacturing process for your part while leveraging our comprehensive range of CNC capabilities, including Electro Discharge Machining (EDM), Swiss machining, turning, and multi-axis milling.

Photochemical Machining

Photochemical machining (PCM), also known as chemical etching and photochemical milling, is a process that produces complex, burr-free, thin sheet metal components using selective masking and acid to precisely remove material.

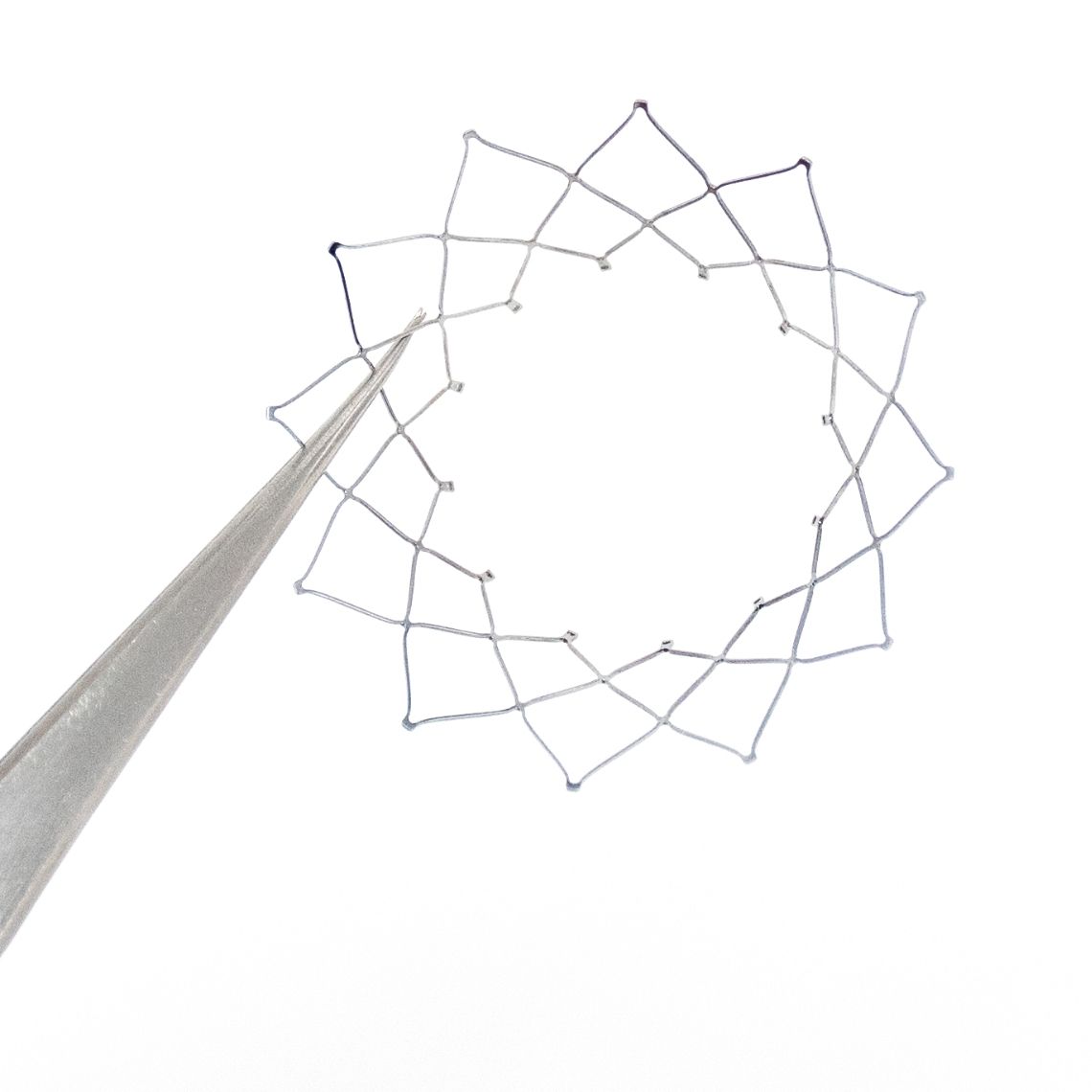

Microforming

Our capability to produce parts with complex shapes and tight tolerances with microforming, coiling, and stamping is supported by our deep process knowledge and in-house precision tooling center.

Micro Waterjet Cutting

We use micro waterjet cutting to produce intricate, high-precision parts with smooth, taper-free sidewalls and micron-level accuracy. This low-impact process handles a variety of materials, creating tight-tolerance components without thermal or mechanical damage.

Electropolishing

We take a scientific approach to electropolishing, delivering flawless surface finishes that meet the highest medical standards with exceptional quality and repeatability. Our process accommodates a wide range of geometries, removing 5–10 microns to enhance smoothness, corrosion resistance, and biocompatibility.

Shape Setting

We apply precise temperature and time control to shape set nitinol, ensuring components achieve and retain their intended form while preserving critical mechanical properties. By accounting for tooling mass and heat transfer across a range of device sizes, we deliver consistent, repeatable results.

Electrical Discharge Machining

We use wire and sinker EDM to achieve precise machining, removing material through controlled electrical discharges without physical contact. This approach preserves the material’s mechanical properties, making it ideal for applications that demand both accuracy and performance.