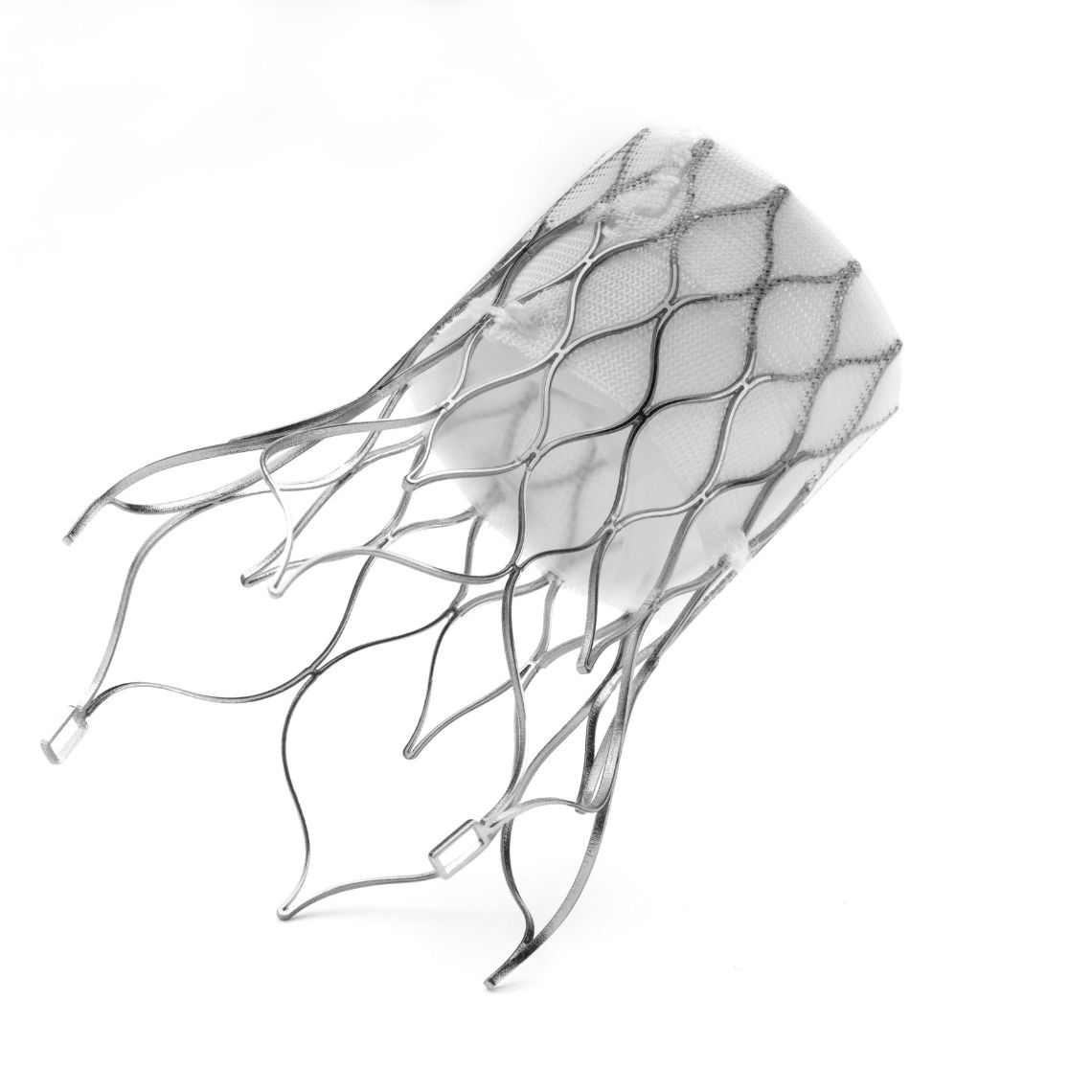

Nitinol Processing

We are experts in nitinol processing technology and understand how it affects the material properties critical to the performance of a finished device or implant. Resonetics® collaborates closely with your team to understand specific application needs and to develop customized solutions that help you achieve your manufacturing and part performance goals.

Laser Cutting

We are experts in using ultrafast femtosecond laser systems to perform precision cutting of nitinol, resulting in highly accurate shapes with little need for additional post-processing. This results in minimal thermal damage, less downstream processing, and faster turnaround times.

Learn More

Shape-Setting

We offer multiple nitinol shape-setting processes using precise temperature control, advanced equipment, and extensive custom tooling expertise. These are supported by in-house resources that enable rapid design and production of complex devices.

Learn More

Electropolishing

We take a scientific, precision-based approach to electropolishing, which produces smooth, corrosion-resistant surfaces that are critical for medical device applications. We have also built our automated electropolishing equipment to improve part quality, reliability, and repeatability.

Learn More

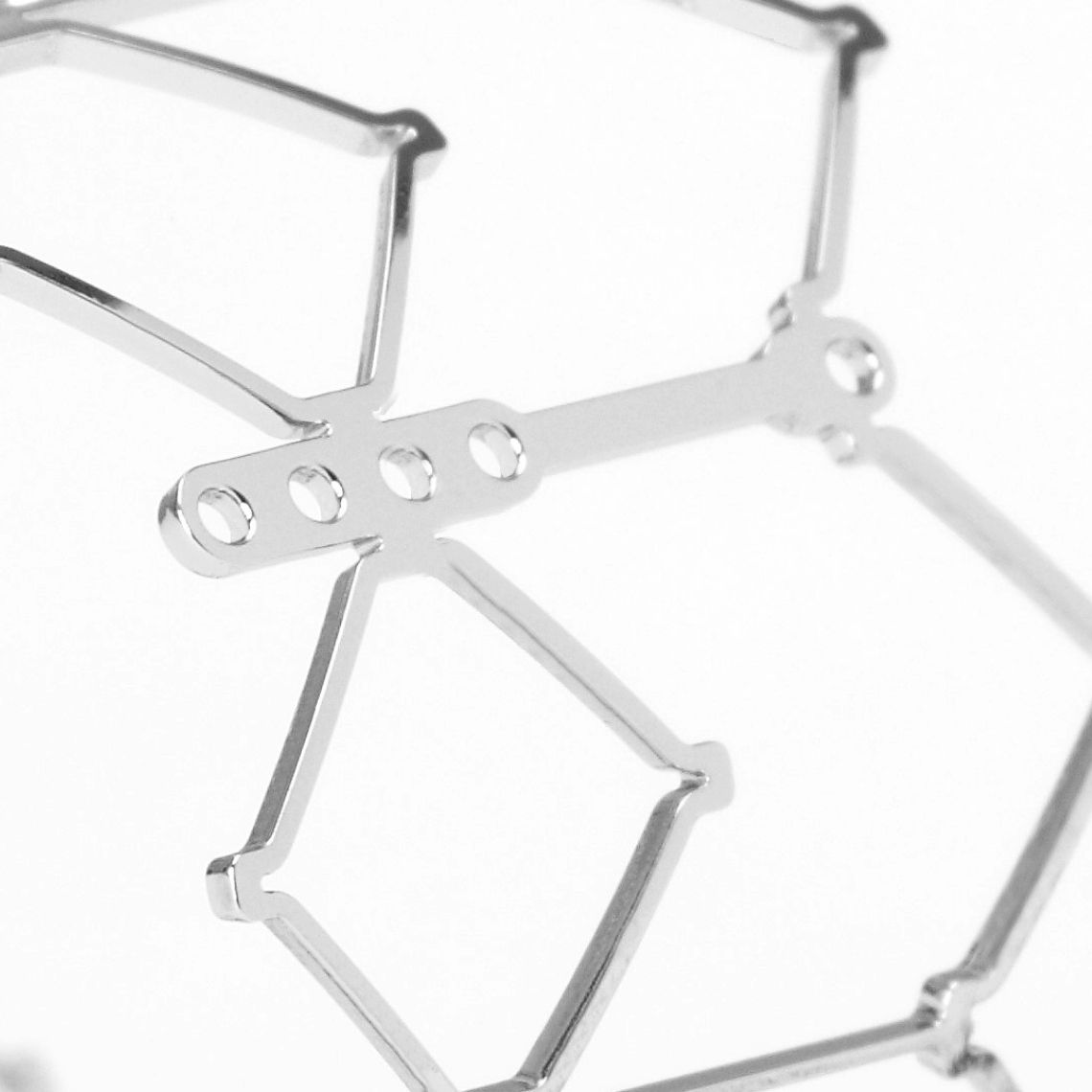

Electrical Discharge Machining (EDM)

Electrical discharge machining (EDM) uses controlled electrical sparks to remove material and create precise features without direct contact between the tool and part. This makes EDM ideal for working with nitinol, as it preserves the material’s superelasticity and mechanical properties.

Learn More