Electrical discharge machining (EDM) is a processing technology where electrical discharges or sparks are used to remove material to produce features in a part. One of the key advantages of EDM is that it removes material without physical contact, which helps maintain the integrity of the part’s mechanical properties. Resonetics® performs both wire and sinker EDM processing to enable larger material removal for orthopedic applications while maintaining precision and process control.

Electrical Discharge Machining (EDM)

EDM Applications

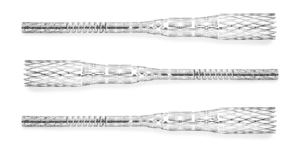

- Bone staples

- Bone anchors

- Drills

- Plates

- Suture retrievers

- Needles with specialty bevels

Key Markets

Our EDM process is used in many different market applications, including, but not limited to:

- Orthopedic

- Dental

- Sports Medicine & Trauma

EDM Materials

We perform electrical discharge machining on a variety of conductive metals, including, but not limited to:

- Stainless steel

- Nitinol

- Titanium