Electropolishing

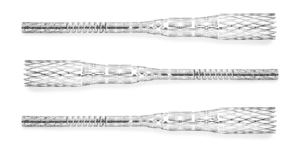

We take a scientific approach to the art of electropolishing nitinol. Our innovative processes and technical expertise enable electropolishing solutions that meet the highest medical standards with exceptional quality and repeatability. No matter the shape or complexity of your parts, we can ensure they receive the flawless surface finishing your precision medical devices and technologies demand.

Standard Electropolishing Specifications

| Min | Max | |

|---|---|---|

| Feature Sizes | 0.012mm | 10mm |

| Wall Thickness | 0.012mm | 0.1mm |

| Outside Diameter | 0.0125mm | 10mm |

| Typical Removal | 5-20% (5-10) microns depending on application and part size | Same |

| Need Outside this range? | Contact us to talk to an Engineer |

Electropolishing

Electropolishing is an advanced electrochemical surface treatment that enhances the performance and reliability of nitinol components. By removing a thin layer of material, the process smooths the surface, resulting in:

- Improved finish

- Superior corrosion resistance

- Enhanced biocompatibility

In many cases, electropolishing also inherently passivates the part, though some customers may still request both processes depending on specific requirements.

Passivation

Passivation is a widely used surface treatment that improves the corrosion resistance of metals through chemical means. The process typically involves:

-

Thorough cleaning: removes unwanted surface materials

-

Oxide layer formation: develops a stable and protective oxide layer, primarily titanium dioxide, that enhances corrosion resistance and biocompatibility