Sensor Technology

Advanced MedTech devices depend on precise, reliable data collection. We provide standard and custom sensor solutions that measure critical parameters such as pressure, strain, and temperature, helping you capture the data that drives performance and patient outcomes. From concept to deployment, our team works alongside yours to ensure the optimal fit for your application, offering support in design, integration, and testing.

Fiber Optic Sensors

Our fiber optic sensor team has developed a suite of standard sensor products and readout units designed for seamless integration into catheter devices. If one of our standard sensors is not the right fit, we can design a fully custom fiber optic sensor tailored to your device.

Electromechanical Sensors

Our electromechanical sensor team partners with you to define the specific measurement needs of your device and develop the right sensor technology for your application. This includes designing the sensor, integrating it into a device or subassembly, and developing a complete testing protocol.

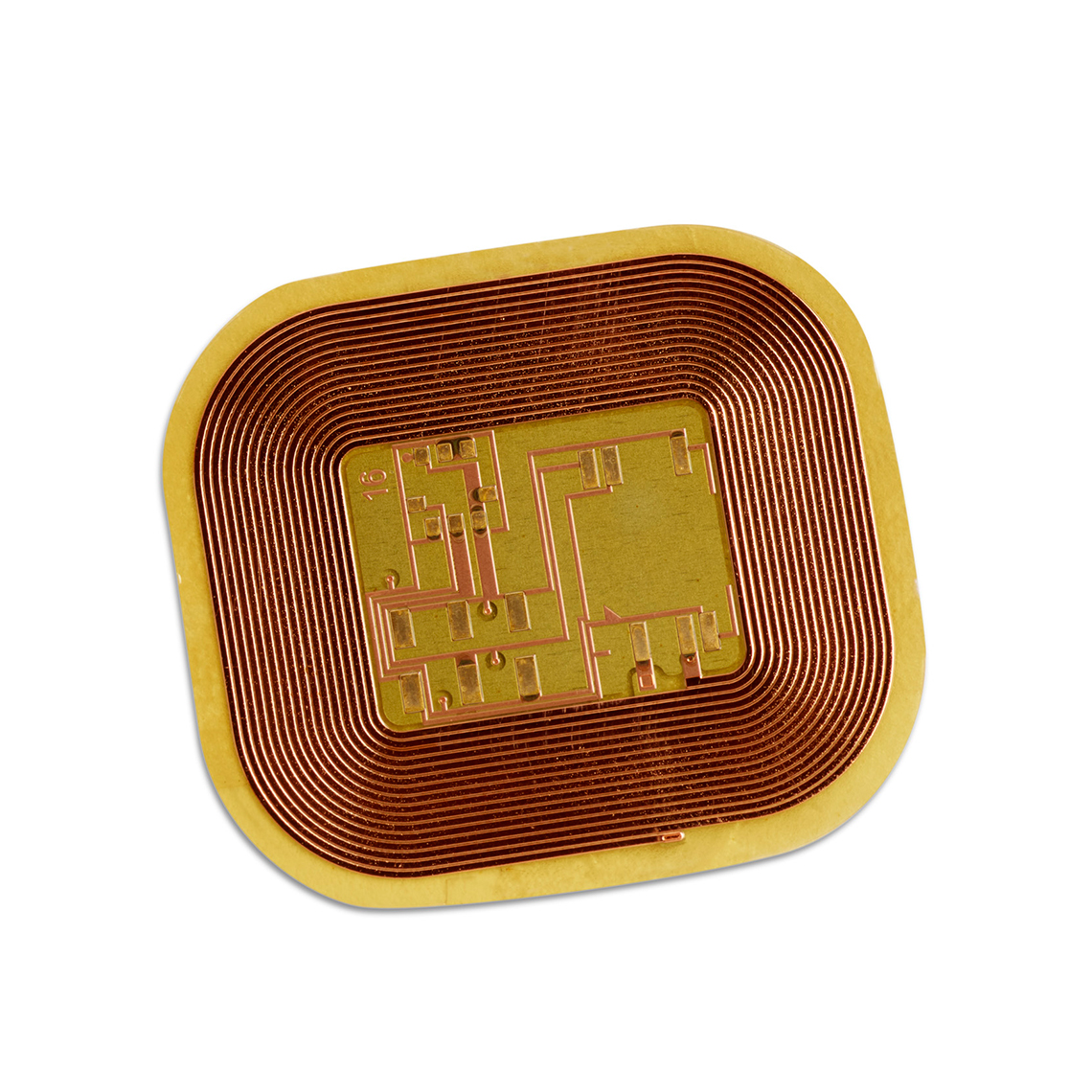

NFC Coils

We are a leader in planar Near Field Communication (NFC) coils for single- and multi-use medical devices. These low-power, wireless coils enable secure data transfer and integrate easily with sensors that monitor temperature, pressure, and other vital signs.

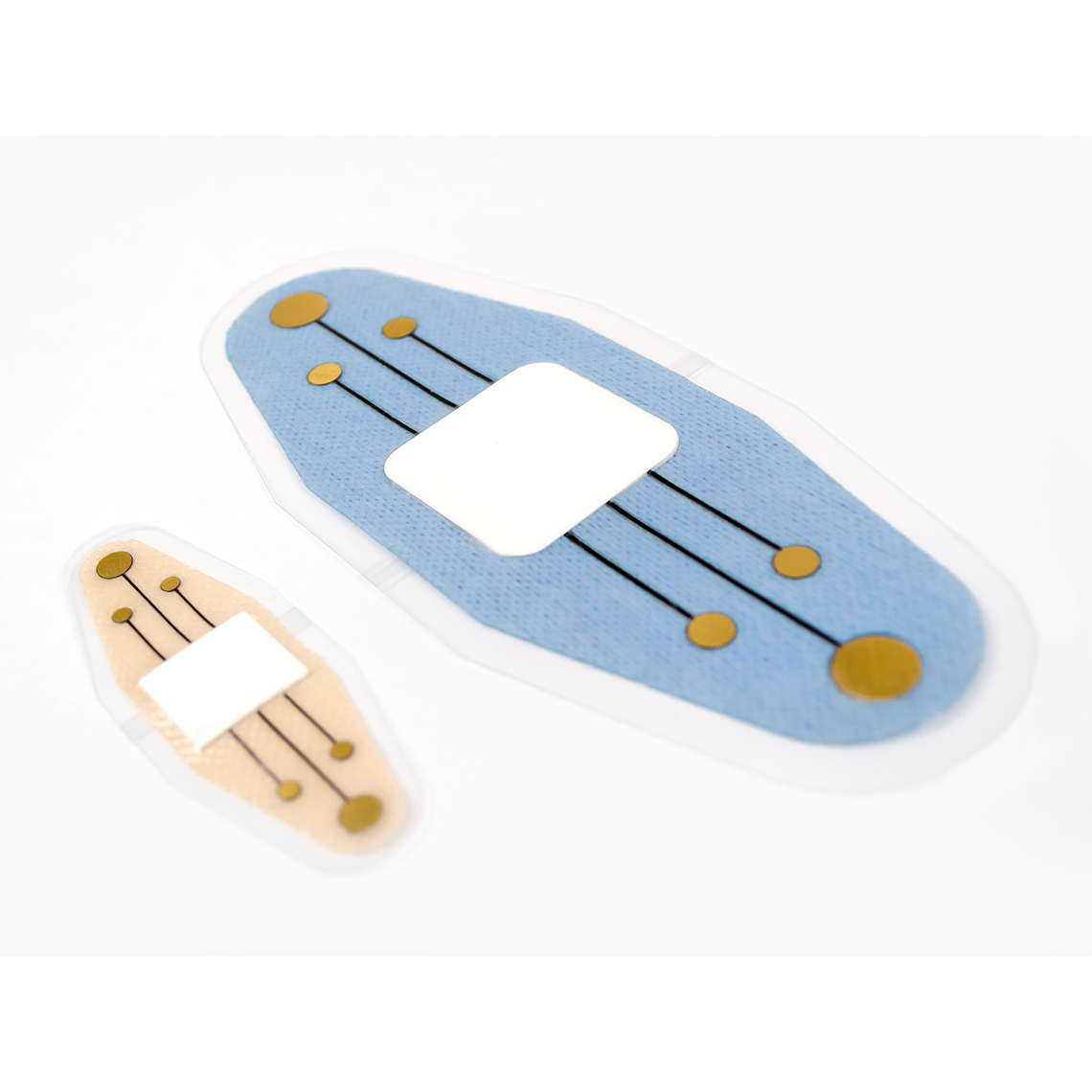

Wearable Biosensors

We design and manufacture wearable biosensors that monitor vital signs, sweat analytes, and other health indicators such as heartbeat, blood pressure, motion, and body temperature. These devices collect critical patient data to support a more proactive approach to care in applications such as body sensors, cardiac monitors, and continuous glucose monitoring (CGM).

Sensor Design & Development

MedTech companies are incorporating data collection capabilities into their devices to provide clinicians with critical feedback to help improve patient outcomes. While it may be evident what data is needed during a procedure, collecting it can be highly challenging. Our experienced engineers can take the lead in designing and developing a custom sensor to meet the exact requirements of your project. Based on your application and the type of data you need to measure, we determine the optimal technology and engineer a custom sensor that both meets your performance criteria and integrates into your device. We then run a development program to iterate the design as needed, refining the specifications and performance requirements, including accuracy, resolution, and response time.

Integration & Testing

We integrate standard and custom sensors directly into subassemblies, catheter delivery systems, and medical devices, ensuring they capture accurate data during use. Our engineers address critical design considerations, including device behavior, steerability, and how size can affect sensor performance. By delivering finished subassemblies with sensors securely attached, we help eliminate errors, streamline production, and ensure devices function as intended.

We also develop and execute rigorous testing protocols to verify sensor performance. For fiber optic sensors, we test and calibrate each unit before shipment, while electromechanical sensors are tested throughout manufacturing to maintain reliability. Our team designs functional test methods and equipment, performing testing both before and after device assembly to ensure consistent, high-quality outcomes.

Solving Complex Challenges

Developing complex sensors and successfully integrating them into medical devices comes with many obstacles. Work with our team to help take on all types of design challenges, including, but not limited to:

- Size constraints

- Determining sensitivity and accuracy

- Minimizing failure modes

- Qualification requirements

- Manufacturing volumes

- Robustness for sterilization cycles