Knowledge Center

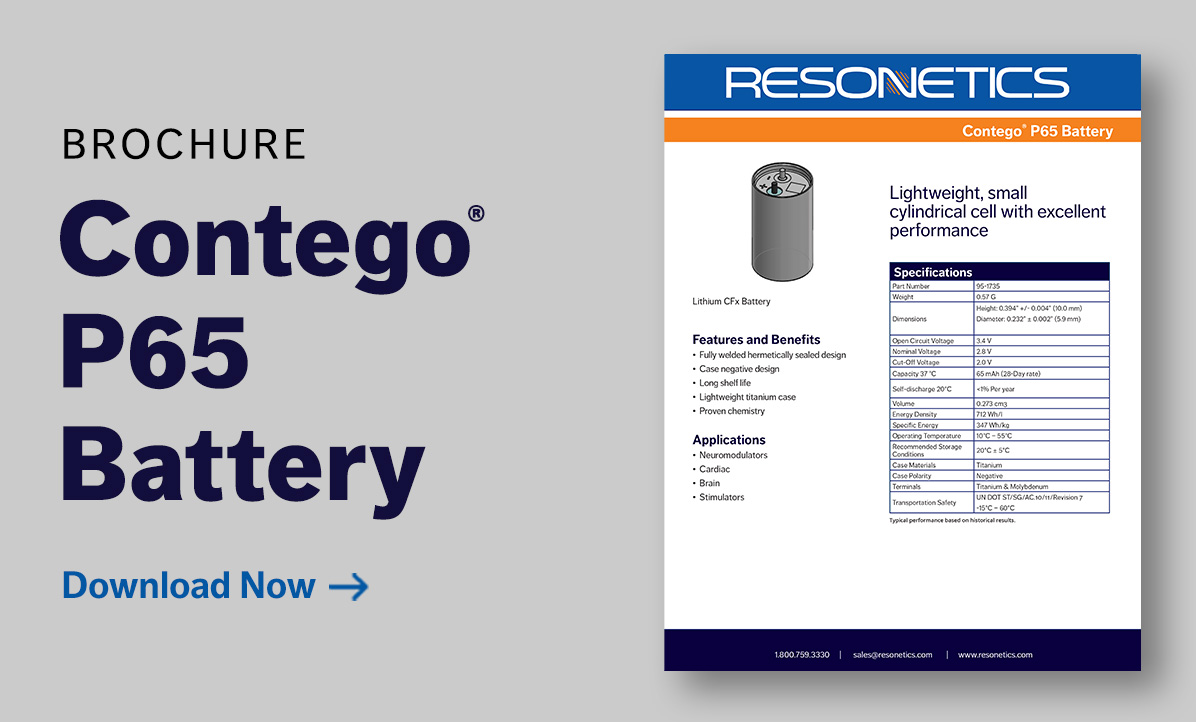

BROCHURE

Contego® P65 Battery

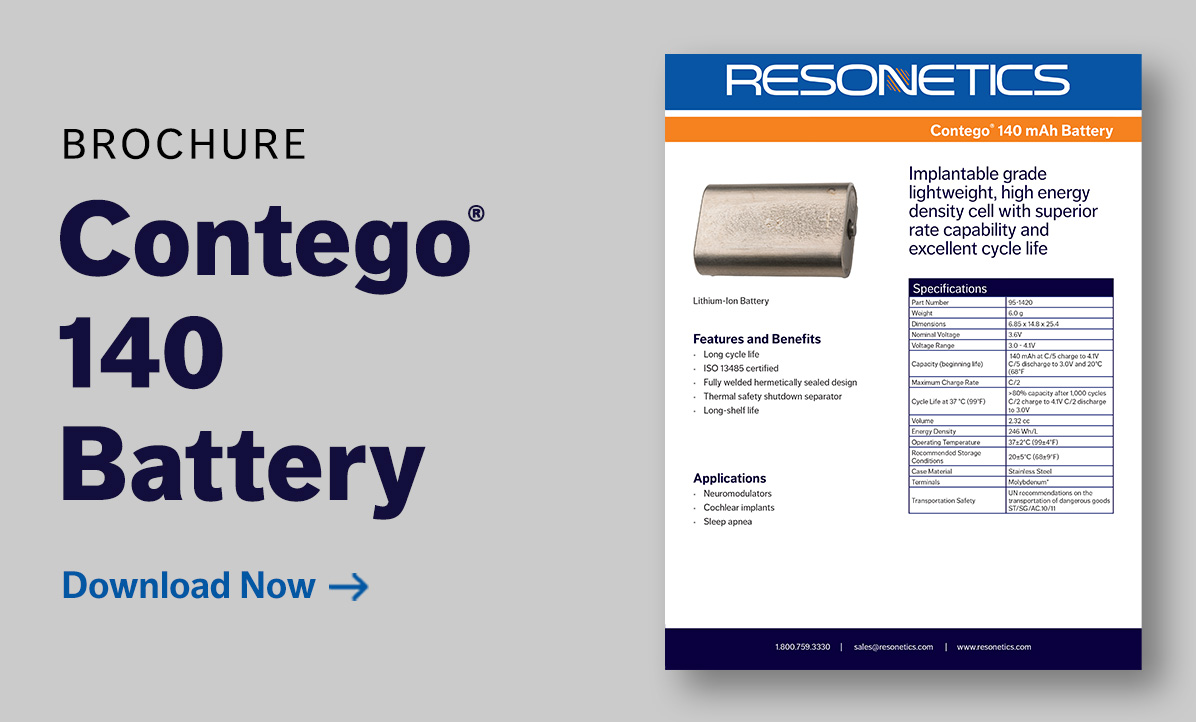

BROCHURE

Contego® 140 Battery

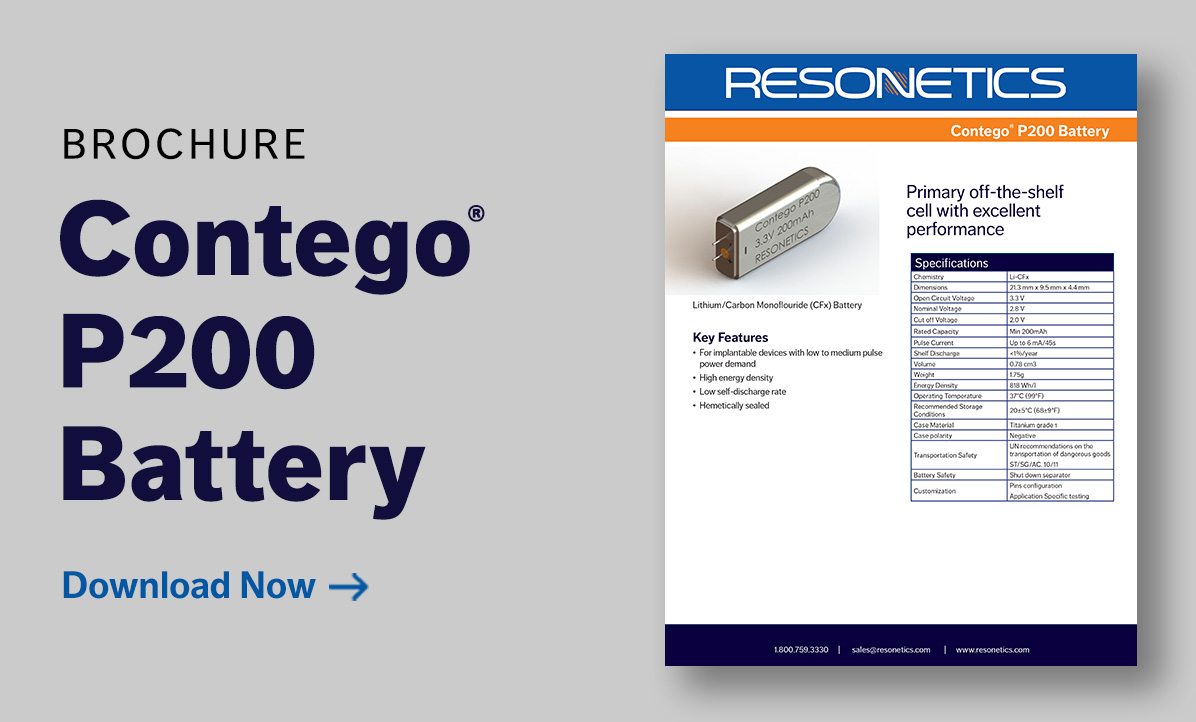

BROCHURE

Contego® P200 Battery

NEWS

Resonetics Completes Acquisition of Memry and SAES Smart Materials

NEWS

Resonetics Introduces New Contego 200 mAh Primary Battery

BLOG

The Ultimate Guide to Micro Manufacturing in MedTech and Life Sciences

BLOG

Automated and Manual Microfluidic Placement Comparison

NEWS