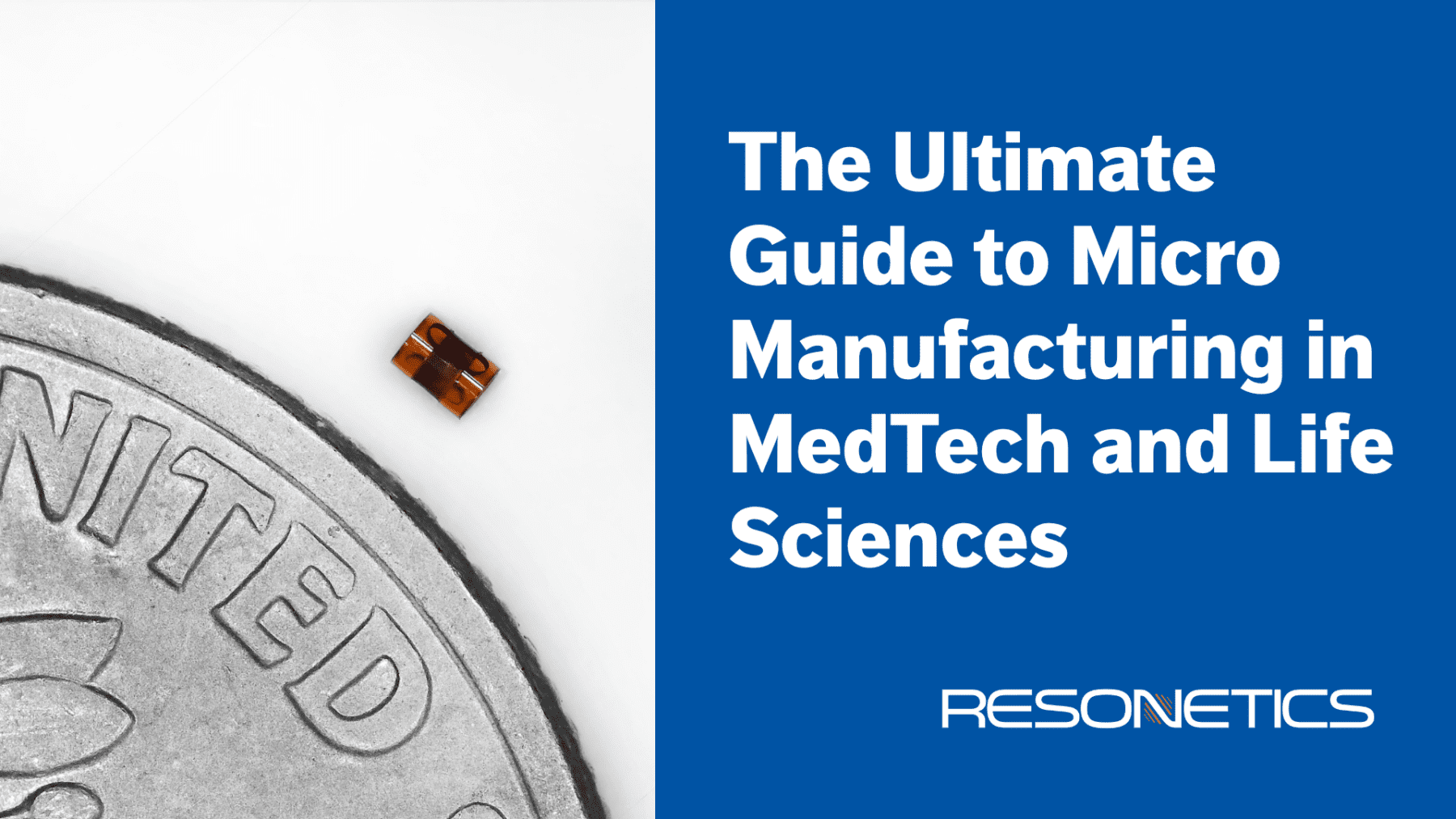

The Ultimate Guide to Micro Manufacturing in MedTech and Life Sciences

The medical technology (MedTech) and life sciences markets are dynamic and rapidly evolving sectors that play a crucial role in revolutionizing healthcare. These markets comprise a wide range of innovative devices, equipment, and software, that are improving patient care, diagnostics, and treatment outcomes. These industries leverage cutting-edge advancements in science and engineering to create groundbreaking solutions that bridge the gap between medicine and technology. Many of the advancements in MedTech and life sciences devices are focused on creating smaller devices that can perform more minimally invasive procedures that have a reduced impact to patients. To support the continued advancement in the MedTech and life sciences industries, companies are relying on advances in micro manufacturing technologies to produce miniature devices and components.

What is Micro Manufacturing?

Micro manufacturing is a cutting-edge technology that involves the production of miniature components, structures, and devices with exceptional precision and accuracy. This field caters to the fabrication of microscopic parts that often measure less than one millimeter in size. The process involves intricate design, specialized manufacturing and inspection equipment, and high-precision techniques to ensure the utmost quality and consistency of the final product. Resonetics is a leader in micro manufacturing for the MedTech and life sciences industries, developing a wide variety of processing capabilities to manufacture components, sub-assemblies, and devices. These micro manufacturing capabilities are separated into the categories of laser processing, nitinol processing, and metal fabrication. This blog will present more detailed information about Resonetics’ micro manufacturing capabilities.

The Different Types of Micro Manufacturing

Laser Processing

Laser micro manufacturing is a compilation of technologies successfully addressing an ever-increasing demand for micro-scale manufacturing in the Medical Device and Advanced Diagnostics markets. These technologies include laser ablation, 3D laser micro machining, laser cutting, laser drilling, laser welding, laser marking, and laser cut hypotubing. Each technology addresses a common medical device manufacturer’s need to fabricate micro-scale medical devices and components in metals, polymers, glasses, or a combination of those materials. The advantage of using a laser over traditional mechanical processes includes no part contact, high precision and accuracy, high speed, less waste materials, a simple one-step process for complex geometries, and the ability to produce micron-scale features with minimal heat input. The most common types of lasers used in micro manufacturing are fiber, excimer, femtosecond, picosecond, and Nd:YAG. Here is some more information about different laser processes for micro manufacturing:

Laser Cutting

Laser cutting uses a focused laser beam to melt or ablate material, which is simultaneously removed with the help of a coaxial gas nozzle. This process is well-established and used extensively in the manufacturing of medical devices, including catheter stents, delivery system components, and components or implants requiring complex geometry across the overall length. Different types of lasers are chosen based on the material to be laser cut, feature size, and tolerances. Laser cutting of medical devices and components used to primarily uses a Nd:YAG or fiber laser. Femtosecond and picosecond lasers have gained popularity in recent years because they minimize heat input into the material, resulting in no heat affect zone (HAZ), clean cut edges, and no burrs. At Resonetics, we design and build in-house our own state-of-the-art custom laser workstations which combine the laser cutting benefits of femtosecond lasers with a processing speed that makes them more economical than what was previously available.

Laser Welding

Laser welding is a process that joins two parts without the use of filler material. Welding can be achieved between similar and sometimes dissimilar materials (different metals or metals and polymers). The process utilizes a focused laser beam to produce welds with minimal heat-affected zone, which maintains the integrity of the base material and prevents distortion of the final assembly. This makes laser welding particularly useful for micro-fabrication applications, which involve parts that are too small to be joined by traditional welding methods. At Resonetics, our deep process knowledge and state-of-the-art equipment allow us to solve complex manufacturing problems and perform laser welding at a micro-scale.

Laser Ablation

Laser ablation is a method of selectively removing material, resulting in micron-scale features on micro- or macro-scale metal, polymer, or glass components. The material is selectively removed via direct vaporization resulting from the exposure to a focused laser beam. Laser ablation has been a beneficial process for advanced micro manufacturing of medical device applications because it offers a wide range of material compatibility, resulting in a diverse scale of products. At Resonetics, we employ a variety of laser tools, including ultrafast (femtosecond and picosecond), excimer, diode-pumped-solid-state, and fast-scanned CO2 lasers. ASSURE Endpoint Detection is a patented process we developed for our custom reel-to-reel wire ablation platform that solves a common challenge of removing eccentric multi-layer coatings from wires by using a closed-loop detector to adjust the laser ablation process in real-time, accommodating local inconsistencies in coating thickness.

3D Laser Micro Machining

3D laser micro machining is an ablation process that uses a galvo based laser beam delivery system to machine material, resulting in micron-scale features on micro or macro scale metal, polymer, or glass components. 3D laser micro machining is possible with ultrafast femtosecond lasers, a technology that allows athermal ablation of a material given the right parameters and conditions. The energy in a focused femtosecond laser pulse can be so great and concentrated that material particles are either vaporized or ejected away in a period so short that heat cannot transfer to the base material. Correctly applying this technology allows for components to be made that would not be possible in any other technology, with significantly less heat affecting the surrounding material. At Resonetics, 3D laser micro machining can be as simple as a slotted hole added to a sheet or tube, or an intricate complex geometry created by our proprietary MICRABLATE 3D Laser Machining process, a selective laser ablation process that strategically removes material layer by layer to produce an innovative micro-scale component.

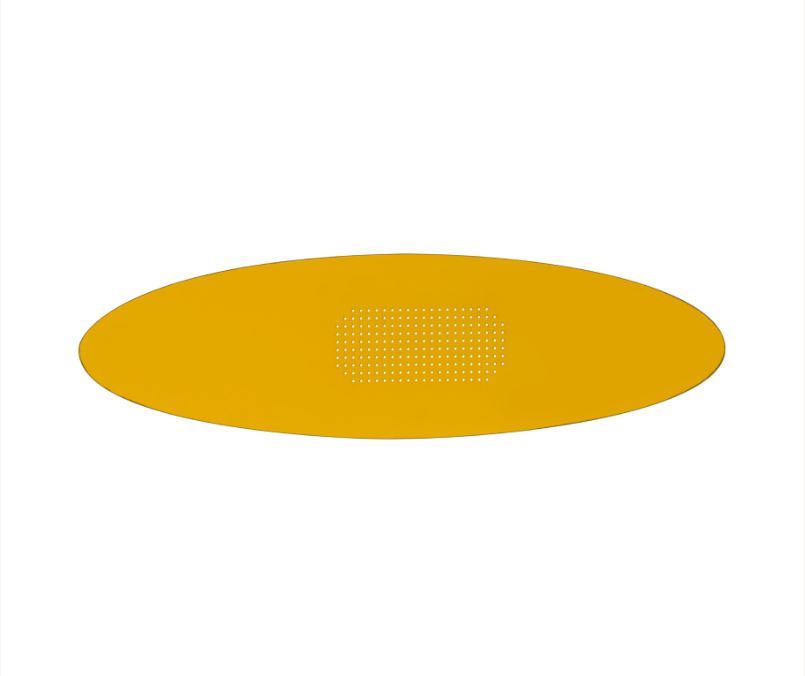

Laser Drilling

Laser drilling is an ablation process that uses a focused laser beam to create micron scale through-holes. The process uses a focused laser beam to drill holes in a wide variety of materials, including metals, polymers, and glass. Laser drilling enables the fabrication of holes down to single microns in diameter, which cannot be achieved by standard drilling methods. The process can also be performed on a wide variety of metals and polymers, eliminating heat damage, and maintaining the integrity of the product being manufactured. Some popular applications that use laser drilling are embolic protection filters, infusion catheters, and drug delivery balloons. Resonetics can laser drill holes as small as a few microns and can drill thousands of these holes simultaneously through thin polymer materials.

Laser Marking

Laser marking is a process that uses a focused laser beam to create permanent marks on the surfaces of target components. It can be used to put a variety of logos, barcodes, or alphanumerics onto a piece of material. The laser marking technique entails generating focused light beams containing high energy to be directed at the surfaces of materials. As a result of the light beam interacting with the surface of the component, there is a transfer of heat. Therefore, the appearance, namely, reflectivity or color, of the marked material surface changes, creating visible contrast. This allows high precision in the marking used on target components. At Resonetics, we apply our advanced laser processing knowledge to achieve consistent and precise laser marking across a variety of materials.

Laser Cut Hypotubing (PRIME)

Laser cut tubing (LCT) involves using a focused laser to melt or ablate through one wall of a metal or polymer tube and remove the degraded material with the help of a high-pressure coaxial gas nozzle. The process has been used in medical device manufacturing for over 30 years with major advancements following the push for miniaturization for minimally invasive procedures. For catheter delivery systems, this process has been too slow and costly to incorporate. However, Resonetics has combined advances in laser and motion control to develop a cost-effective tool for high-volume manufacturing of catheter components. This high-speed laser cutting process is branded as PRIME Laser Cut.

Metal Laser Processing

Laser processing can work with many metals used for medical device components. Common metals that are used in medical applications are stainless steel, nitinol, titanium, and cobalt chrome (CoCr). The advantage of using a laser over traditional mechanical processes includes no part contact, ability for micron scale features and minimal heat-input with highspeed lasers. At Resonetics, we custom-build our own laser processing systems to provide the best manufacturing solution for each application.

Polymer and Glass Laser Processing

There are a variety of polymer and glass materials that can be laser processed to fabricate medical device components and implants. This includes polyethylene (PE), polyurethane (PU), Polyimides (PI, Kapton), fluoropolymers (PTFE) PET, and silicones. Laser techniques can be used to fabricate polymer devices with a variety of high-precision patterns at different lengths, remove polymer coatings, and drill holes in polymer balloons. Resonetics is a leader in laser processing for polymer and glass applications.

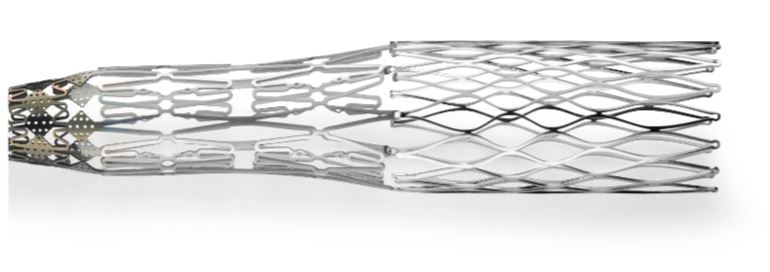

Nitinol Processing

Nitinol is a nickel-titanium alloy used in many critical MedTech applications. The material has unique shape memory and superelastic properties that enable it to restore its original shape when deployed and withstand challenging biomechanical motions without mechanical deformation or loss of mechanical integrity. Nitinol is commonly used in minimally invasive medical device components such as catheters and guidewires, and high performance implants such as stents and heart valves. The primary manufacturing processes for nitinol, including laser cutting, laser welding, 3D laser micro machining, shape setting, oxide removal (chemical or mechanical), electropolishing, (EDM), braiding, electrical discharge machining, CNC machining, and chemical etching. Here is some additional information about each process and Resonetics’ capabilities:

Nitinol Laser Cutting

Nitinol laser cutting involves using a focused laser beam to melt or ablate nitinol material that is simultaneously removed with the help of a coaxial gas nozzle. Nitinol laser cutting was originally performed by fiber lasers that melt the nitinol and then use a gas to eject the molten material. Fiber lasers offer a fast cutting speed but require additional post-processing steps to remove recast material and heat-affected zones. Recently, nitinol laser cutting is switching to femtosecond lasers that use very fast bursts of laser to ablate the material into plasma, thereby eliminating the recast slag produced by fiber lasers and minimizing the heat transfer into the remaining material. More modern ultrafast femtosecond lasers have a slower cutting speed than fiber lasers, but reduce the amount of post-processing time required after laser cutting and improve dimensional precision. Resonetics has both fiber and femtosecond nitinol laser cutting expertise, but primarily uses state-of-the-art, ultrafast femtosecond laser cutting machines that are custom-built in-house.

Nitinol Laser Welding

Laser welding is a process that joins two parts without the use of filler material. In laser welding nitinol, it is critical to control the process parameters so that the focused laser beam will produce welds with minimal heat-affected zones, which maintains the integrity of the nitinol base material and prevents distortion of the final assembly. The unique material properties of nitinol limit the types of material that can be laser welded to it. Besides nitinol, titanium and MP35N are the best materials. Nitinol laser welding is particularly useful for micro-fabrication applications, which involve parts that are too small to be joined by traditional welding methods. At Resonetics, our deep nitinol and laser process knowledge and state-of-the-art equipment allow us to solve complex manufacturing problems and perform nitinol laser welding at a micro-scale.

Nitinol 3D Laser Micro Machining

3D laser micro machining of nitinol is an ablation process that uses a galvo-based laser beam delivery system to machine nitinol, resulting in micron-scale features on micro- or macro-scale components. Nitinol 3D laser micro machining is possible with ultrafast femtosecond lasers, a technology that allows athermal ablation of a material given the right parameters and conditions. The energy in a focused femtosecond laser pulse can be so great and concentrated that material particles are either vaporized or ejected away in a period so short that heat cannot transfer to the base material. Correctly applying this technology allows for components to be made that would not be possible in any other technology, with significantly less heat affecting the surrounding material. At Resonetics, 3D laser micro machining can be as simple as a slotted hole added to a sheet or tube, or an intricate complex geometry created by our proprietary MICRABLATE 3D Laser Machining process, a selective laser ablation process that strategically removes material layer by layer to produce an innovative micro-scale component.

Nitinol Shape Setting

Nitinol shape setting, or heat setting, forms the part into its as-deployed configuration while simultaneously tuning the transformational and mechanical properties to meet key performance attributes (e.g., radial outward force). A laser-cut nitinol component is mounted on a custom fixture or mandrel and then heat-treated to set the shape. Often, the shape setting process is done in several stages to reduce the strain on the material and preserve the mechanical integrity. Resonetics designs and manufactures these mandrels and custom fixtures using custom automated shape setting equipment to repeatably process the Nitinol components to precise dimensional and mechanical performance specifications.

Nitinol Oxide Removal

Shape setting, unless performed in an inert environment, creates a thermal oxide on the surface of nitinol components that may not be biocompatible. For applications in which the component is expected to survive hours or days within the human body, removal of this non-biocompatible oxide is performed using mechanical means, chemical etching, or both. Mechanical removal of oxide is achieved through blasting with an ultrafine abrasive powder or via tumbling in an abrasive media (e.g., ceramic). Chemical removal of oxide is achieved using one of several proprietary recipes intended to dissolve the deleterious oxide and prepare the surface for electropolishing. At Resonetics, we utilize automated mechanical and chemical methodologies to ensure uniform oxide removal without damaging the underlying structural metal.

Nitinol Electropolishing

Electropolishing is an electrochemical process that is used to round edges and remove damage from upstream processes (e.g., slag, burrs, and heat-affected material). It is also used to form a controlled, passive oxide layer on the surface of the material that renders the device biocompatible. To perform electropolishing, Nitinol components are connected to an electric current and put in an acid solution for a specified amount of time. Resonetics is applying innovation and technical know-how to improve the consistency of the electropolishing process. Our team has taken a scientific approach to the “art” of electropolishing nitinol and developed our own proprietary electropolishing equipment capable of tight tolerance controls and batch processing.

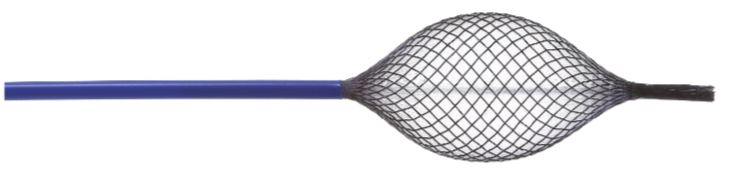

Nitinol Braiding

Nitinol braiding is a form of nitinol processing that involves interlacing nitinol wires to create robust and flexible structures that can be used for medical devices or implants. Common applications are flexible catheter shafts and stents. Nitinol braiding is essential to a wide range of applications within modern medical devices and technologies, including catheter components, stents, heart failure implants, and flow diverters. Resonetics has horizontal braiding capabilities in 24/48 or 42/82 configurations.

Nitinol Electrical Discharge Machining (EDM)

Electrical Discharge Machining is a processing technology where electrical discharges or sparks are used to remove material to produce features in a part. Nitinol EDM is a desirable process because the removal of material does not require any physical contact of a tool with the part, so the superelasticity of the material will not affect the manufacturing process. It is particularly suited for applications such as orthopedic staples and bone anchors in which the device size is large compared to the ultrafine feature sizes of cardiovascular devices. Resonetics performs both wire electrical discharge machining (WEDM) and sinker EDM processing of nitinol to produce complex parts with tight tolerances.

Nitinol CNC Machining

Computer numerical control (CNC) machining involves using a tool to physically remove material from a part. There are several CNC processes, including horizontal, vertical, multi-axis, and Swiss machining. Nitinol can be a challenging material to machine due to the superelastic properties of the material, which create substantial springback and tool wear compared to conventional metals. Our experienced engineers and machinists leverage a comprehensive range of CNC capabilities to produce nitinol components and implants, and can also combine our CNC machining capabilities with other manufacturing processes to produce designs that a single manufacturing process can’t produce (e.g., threading).

Nitinol Photochemical Machining

Nitinol photochemical machining, photochemical etching, or chemical etching, provides a method of fabricating tight tolerance, precision features into nitinol with highly concentrated acid. The nitinol photochemical machining starts with a patterned photoresist, followed by acid exposure, removal of photoresist, and finally part cleaning. The process is a batch or parallel process that enables multiple parts to be fabricated at one time. The photochemical etching process dissolves the nitinol material, which produces burr-free edges and no heat-affected zones. Resonetics has advanced photochemical machining processes that can produce unique features in nitinol, such as blades and sharps.

Nitinol Material

Nitinol is a nickel-titanium alloy used in many critical MedTech applications. The performance of the raw material is directly related to the level of control maintained throughout the production process. Nitinol material is initially produced in an ingot, which is further processed into different forms for further processing. The common forms of nitinol material used in micro manufacturing for medical device components are tubing, wire, sheet, ribbon, and powder. Our manufacturing technologies have been established to accept any input material that our customers prefer or specify.

Metal Fabrication

The are many different metal micro manufacturing processes for medical device components and implants. At Resonetics, we label these different processes under the category of metal fabrication. The processes in this group are centerless grinding, CNC machining, photochemical machining, stamping, coiling, and microforming. Here is some more information about each of these processes:

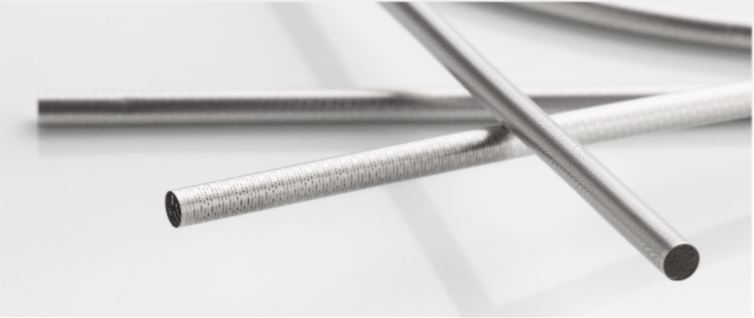

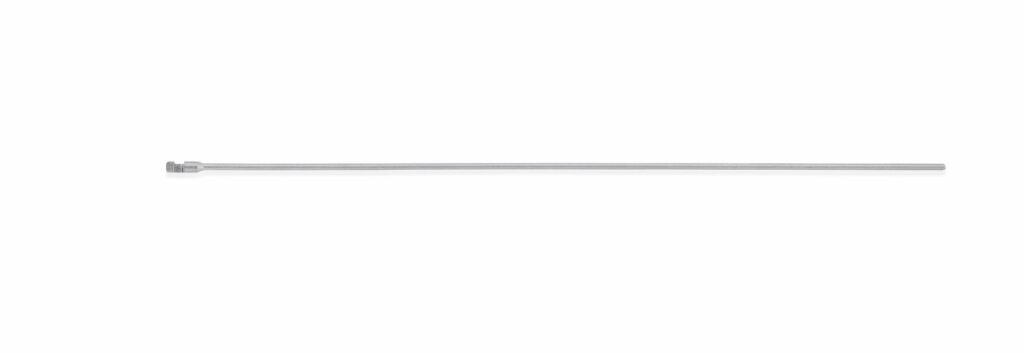

Centerless Grinding

Precision, or centerless grinding, uses a grinding wheel, work blade, and regulating roller to selectively remove material on a wire. The process works through the regulating roller and the grinding wheel rotating in the same direction causing the part to counter rotate against the work blade. This process gained popularity because it enables the production of guide wires by selectively removing the outside diameter to enhance the flexibility required to navigate the circulatory system. Materials that can be precision ground range from ceramics to metals to polymers, with the most typical raw materials used in the medical device market being stainless steel and nitinol wire and tube. Resonetics’ precision grinding process enables a nearly limitless level of micro-scale geometries for mandrels, guide wires, core wires, and catheter components, with expert process knowledge, machine fabrication, automation, and 100+ grinding systems.

CNC Machining

Computer numerical control (CNC) machining involves using a tool to physically remove material from a part. There are several different CNC machining processes, including milling, turning, and Swiss. Milling involves using rotating cutting tools to remove material from a workpiece, resulting in a desired shape or surface. Turning utilizes a rotating workpiece while a stationary cutting tool removes material from the part. Swiss Machining uses a collet and bushing configuration that enables the machining of ultra-fine features on parts going down to 25 micrometers in diameter. There are a broad range of applications enabled by precision machining including micro scale implants, catheter components, and delivery system components. Resonetics has machining capabilities with a broad range of equipment including Swiss, horizontal, vertical, and multi-axis CNC tools.

Photochemical Machining

Photochemical machining, photochemical etching, or chemical etching, provides another method of fabricating tight tolerance, precision features in micro-scale metal components. The process starts with a patterned photoresist, followed by acid exposure, removal of photoresist, and finally part cleaning. The process is a batch or parallel process that enables multiple parts to be fabricated at one time. Photochemical etching has gained continued implementation in the medical device market, with example applications including surgical jaws and blades, skin abraders, and needles. Resonetics has realized significant advancements in the photochemical machining process, including applications like blade sharpening.

Stamping

Metal stamping is a highly efficient and precise manufacturing process that involves feeding flat sheet metal into a stamping press, where a die and a punch work together to shape and cut the metal into the desired form. The die contains cavities and contours that impart the desired shape and features to the metal, while the punch applies force to deform the metal and separate it from the surrounding material. Metal stamping offers several advantages for medical device manufacturing, including the ability to produce complex and intricate geometries with tight tolerances. It enables the mass production of components with high repeatability, ensuring consistent quality and minimizing variability, and is commonly utilized to manufacture medical device components used in surgical instruments and catheters. Resonetics has an in-house precision tooling group that produces progressive stamping dies for piece, part, coil, or strip processing of various metal alloys from 0.0254mm (0.001 in) thick.

Coiling

In the medical device market, the miniaturization of catheters and implants have driven the need for micro coils of various sizes and configurations. The coil winding process includes feed rollers to drive the wire or tube, a guide bushing, and mandrel or deflection tool. For long length (greater than 10 mm) coils the process employed involves the wire being wrapped around the outside diameter of a mandrel. For shorter length coils (less than 10 mm) a deflection tool is used to create the desired coil pitch and diameter. There are a broad range of applications enabled by precision forming, and some examples include catheter reinforcement coils, guidewire coils, radiopaque (marker) coils, embolization coils, delivery/torque coils, and conductor/shocking coils. Resonetics’ precision coiling process was developed with functionality in mind and includes a variety of coil winding techniques that provide the conductivity, flexibility, and radiopacity your device requires.

Micro forming

Precision micro forming of wire and tube meets the medical device market needs for complex wire and tube forms. There are a couple of different ways to perform precision forming with the basics of the process including a method of material holding and a forming tool. There are a broad range of applications enabled by precision forming, and some examples include canula flaring for device insertion and connection, canula bulging for insert molding, single, multiple or helical forms, surgical clamps, grasps, catheter forming tools, and manufacturing and assembly tools. At Resonetics, we routinely combine micro forming with photochemical etching and additional forming processes to push the boundaries of what’s possible in medical device manufacturing.

What Are the Benefits of Micro Manufacturing?

Micro manufacturing has many benefits for the MedTech and life sciences industries due to its transformative impact on product development and patient care. As the medical device industry moves towards more minimally invasive procedures, medical devices and components are getting smaller. Advances in micro manufacturing techniques allow medical device engineers to develop the next generation of innovative medical devices by enabling the creation of these miniaturized devices and components, from implants to diagnostic tools. Micro manufacturing processes can produce intricate features with unparalleled accuracy while ensuring optimal functionality of the device.

Connect with an Expert

This blog has provided an overview of the different micro manufacturing technologies for the medical device and life sciences industries. The best way to learn more is to talk to one of the process experts at Resonetics. Get in touch with the best engineer for your application.