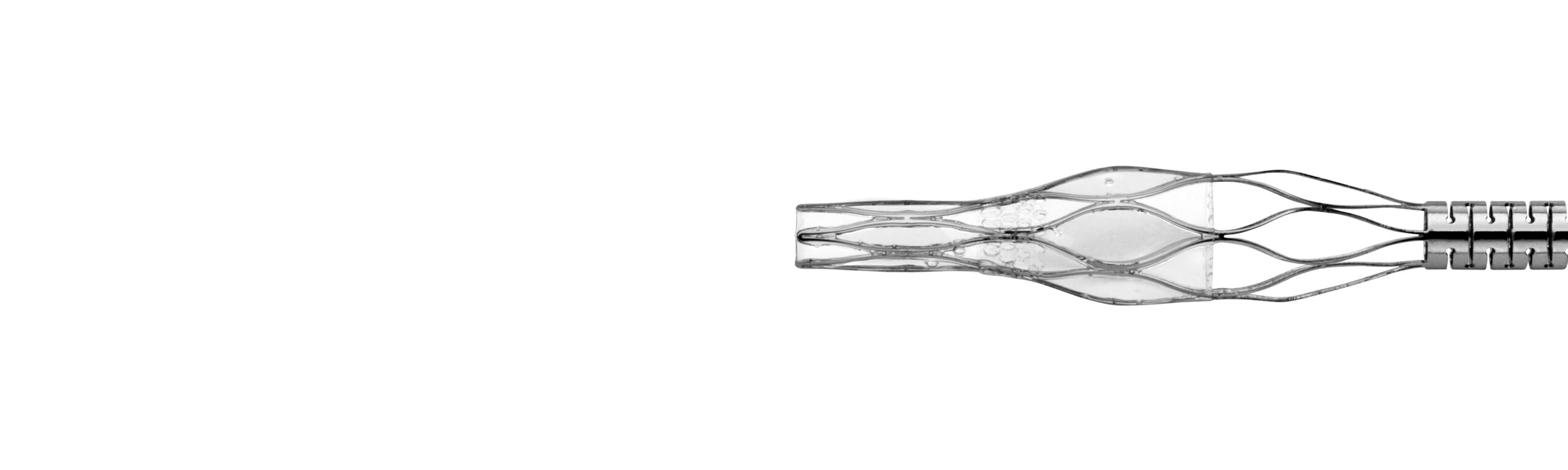

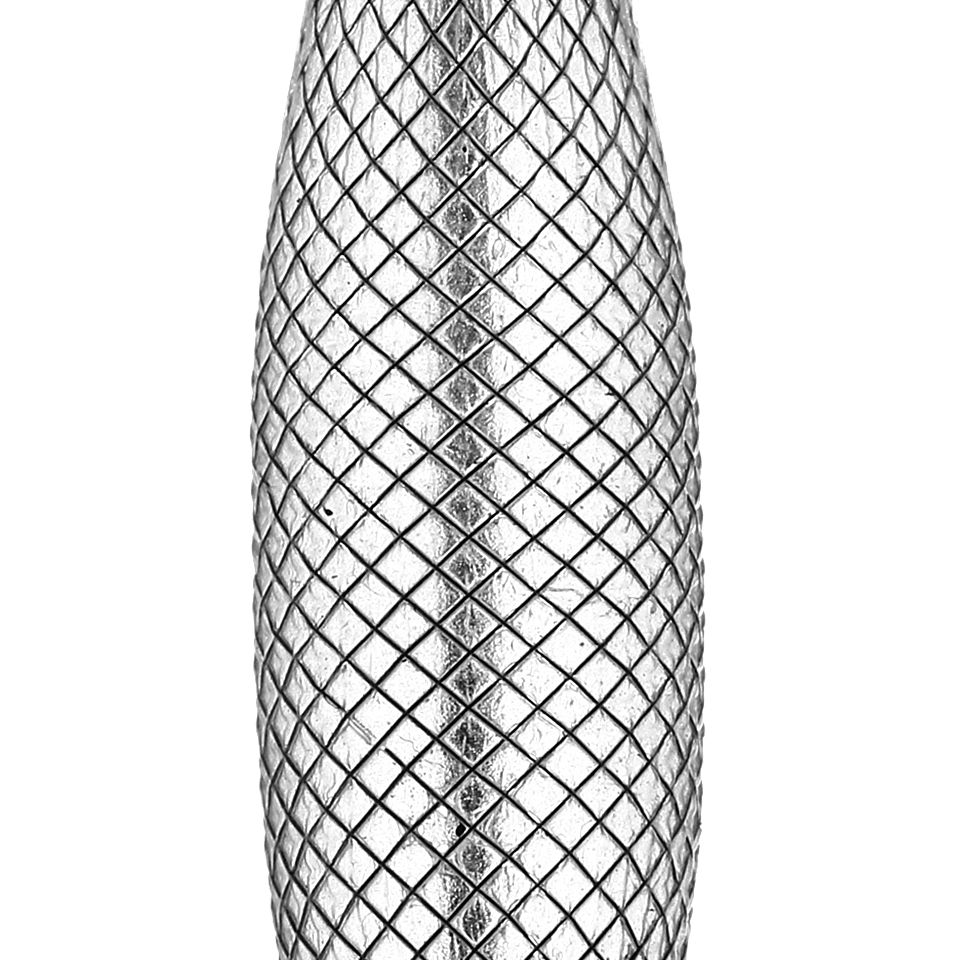

We apply our Medibrane polymer coating to medical devices and implants, including dip coating, spray coating, and molding. Our proprietary adhesion technology improves the bond between metals and polymers, which allows us to improve the performance and technical features created by the coating processes. Our engineers specialize in matching the right polymer cover for each medical application after considering the designated site or tissue, mechanical properties, functional specifications, and unique geometry. We also provide complete device or implant manufacturing solutions by combining our polymer coating capabilities with our other capabilities of nitinol processing, laser cutting and drilling, and cleanroom assembly.

Polymer Coatings

Proprietary Adhesion Process

The key to our industry-leading coating capabilities is our proprietary adhesion process. The first step is surface activation which prepares the metal surface for bonding with a polymeric material. This is followed by an encapsulation coating which encircles the metal surface to form a closed loop or a thin tie layer. This process generates a strong connection between the metal and the encapsulated polymer. The polymer coating is then applied to the tie layer.

Spray Coating

Our spray coating process uses a nozzle that breaks the polymer into tiny droplets and deposits them onto the device or implant. It is commonly used in more complex applications requiring a higher degree of process control. The process uses a mandrel and rotation to eliminate the gravitational forces commonly found with dip coating. This increases the vertical uniformity of the coating thickness. Here are some of the advantages of using spray coating:

- Ultra-thin coating thickness

- Controlled variation of the coating thickness in different areas

- Selective coating

- Different polymer

Dip Coating and Molding

Our dip coating process is a fast and cost-effective method to apply a polymer coating to a device, implant, or mandrel. The process involves lowering the product into a liquid polymer solution and slowly removing it at a controlled speed. Dip coating is generally used in applications where a uniform coating thickness is being applied across the device or implant, and the thickness tolerance is less critical. We also manufacture polymer components or products through a dip molding process. This involves dipping a mandrel into the polymer solution and then removing the polymer coating from the mandrel once it has dried.

Advantages of Dip & Spray Coating Technologies

Laser drilling and cutting can be combined with dip coating technologies through our unique range of processing capabilities. Other advantages include:

- Create an impermeable, non-porous cover

- Suitable for a variety of complex geometries

- Highly accurate with very low cover thickness

- Highly repetitive

- Enables faster and cost-effective process manufacturing with high yield

Coating Materials

Polymer coatings are applied to devices and implants to redirect fluids, enable fluid passage, restrict tissue ingrowth, prevent leaks, and form non-porous and impermeable covers. The most common polymer materials used in medical device coatings are silicone and polyurethane. Here are some of the materials we use in our coating processes:

- Silicone

- Polyurethane

- ePTFE

- TPU

Polymer Coating Applications

Our advanced Medibrane polymer coating processes are used in various medical applications for catheter-based devices and implants. Here are some examples of medtech applications where our polymer coatings are used:

- Embolic protection devices

- Catheter delivery systems

- Aspiration catheters

- Blood flow control catheters

- Occluders

- Neurovascular stents

- Structural heart implants

- Left arterial appendage implants

- Heart valves

- Esophageal stents

- Gastric sleeves