Our advanced Medibrane polymer coatings and coverings capabilities offer improved performance because of our proprietary adhesion technology. This technology activates the surface and improves the bond between metals and polymers. Based on the application, we can then apply a polymer coating to the metal surface or bond a covering made from fabric or polymer. Our engineers are experts in coatings and coverings used in medtech applications and can help you choose the right manufacturing process and polymers to meet the needs of your project and application.

Medibrane Coatings

& Coverings

Proprietary Adhesion Process

The first step of our proprietary adhesion process is a surface activation that prepares the metal surface for bonding with a polymeric material. This is followed by an encapsulation coating which encircles the metal surface to form a closed loop or a thin tie layer. This process generates a powerful connection between the metal and the encapsulated polymer. The polymer coating or covering is then bonded to the tie layer.

Polymer Coatings

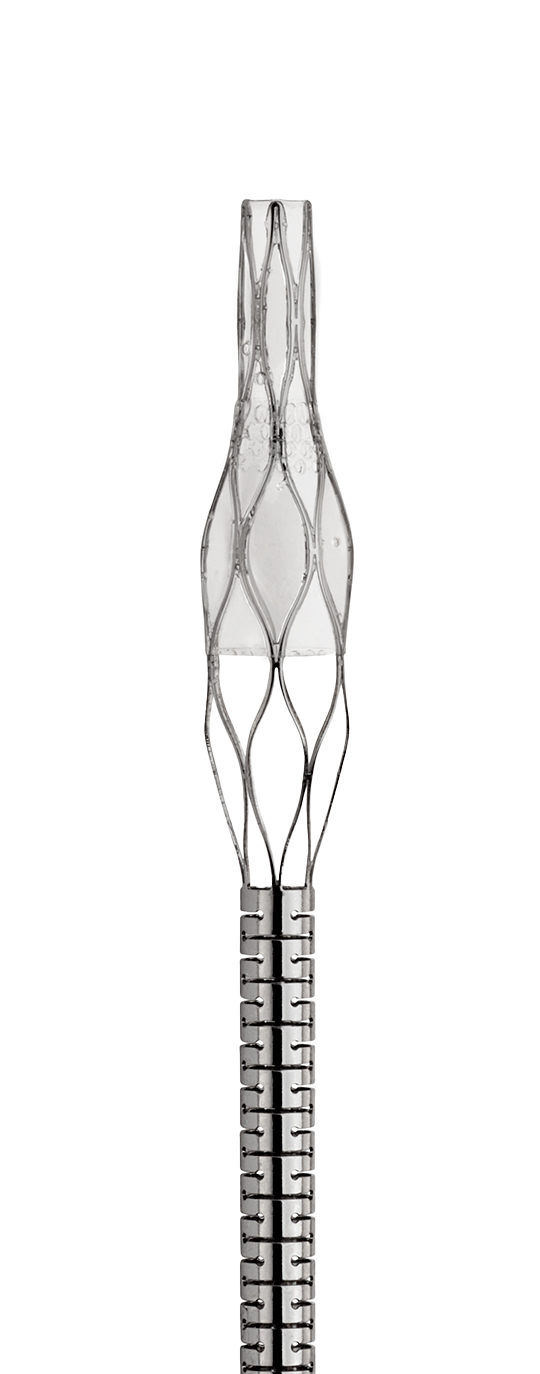

We apply polymer coatings to devices, implants, or mandrels using dip coating or spray coating. Dip coating involves taking a product or mandrel and dipping it into a liquid polymer solution to apply the coating to the surface. Spray coating is applied with a nozzle that breaks a polymer into tiny droplets that are deposited onto a horizontal revolving mandrel that is connected to a stent or scaffold.

Sutureless Covering

Our proprietary sutureless covering technology attaches a polymer or fabric covering onto the surface of a metal stent or scaffold without a manual suturing process.

Coating & Covering Applications

Our polymer coating and covering technology is used in many different medical devices and implants, such as:

- Clot retrieval devices

- Embolic protection devices

- Blood flow reducer components

- Catheter delivery systems

- Occluders

- Neurovascular stents

- Heart valves

- Non-Vascular stents

Advantages of Resonetics Coating and Covering Technologies

- Improved metal and polymer adhesion

- Improved device performance

- Tight coating dimensional control

- Variable coating thickness across the device or implant

- Suitable for a variety of complex geometries

- Selective coating