Resonetics is a leader in micro-manufacturing solutions, offering state-of-the-art stainless steel laser cut tubing services through our proprietary laser cut tubing technology that is designed for precision and efficiency.

Laser Cut Tubing

Key Features

- Unmatched Precision: Resonetics laser cut tubing technology ensures the highest levels of precision with tight tolerances, crucial for applications requiring intricate designs and exacting standards

- Versatile Material Compatibility: Our laser cutting process is compatible with a wide array of materials, including stainless steel, nitinol, titanium, and various polymers, enabling us to meet the diverse needs of clients across multiple markets

- Complex Geometries: Resonetics’ laser cut tubing produces complex geometries and intricate patterns often unattainable with traditional manufacturing methods, making it ideal for advanced components and innovative product designs

- Customization: We understand that each project is unique, which is why our team collaborates closely with clients to develop customized laser cut tubing solutions tailored to their specific requirements and applications, ensuring optimal results

Sizes and Tolerances

Resonetics utilizes both fiber and femtosecond laser cutters to achieve typical beam widths ranging from .001 to .002 inches. We can cut a range of wall thicknesses up to 2 mm, while maintaining tolerances as tight as ±0.00025 inches, even on complex geometries and fine-scale designs.

Examples of Laser Cuts

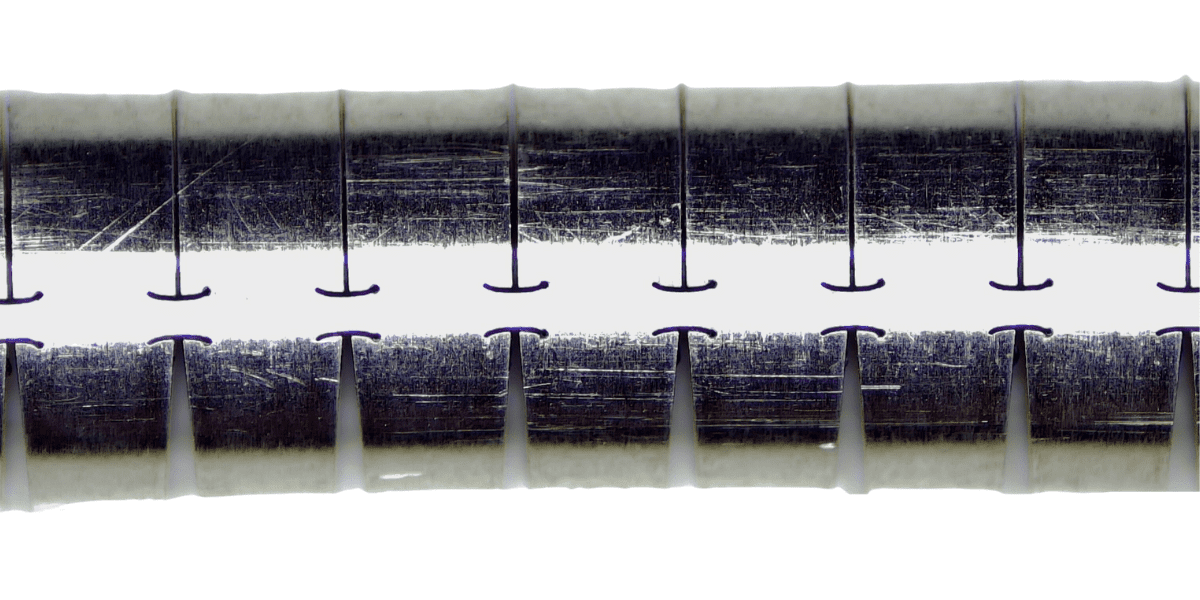

Interrupted Spiral Cut

Interrupted spiral cuts alternate between flexible and solid zones while maintaining a continuous tube structure. This design provides controlled bending and strong torque response, ideal for catheter shafts that need to flex and steer without losing strength.

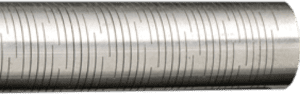

Spiral Cut

Spiral cuts create continuous flexibility along the entire length of the tube, making them ideal for devices that need to navigate tight or tortuous paths, such as delivery systems used in vascular access or neurovascular procedures.

Dogbone Cut

Dogbone cuts are engineered to limit the bending profile of a tube to one or two planes while withstanding significant axial compression and offering strong tensile strength. This design enables precise directional control when navigating tight paths in the anatomy.

Advantages

- High Efficiency: Our laser cutting process is highly efficient, reducing production time and costs while maintaining exceptional quality, enabling quick turnarounds for both small and large production runs

- Consistent Quality: Resonetics’ laser cut tubing technology ensures consistent quality across all products, with rigorous quality control processes that guarantee each piece meets the highest standards of accuracy and durability

- Reduced Waste: Laser cutting is an environmentally friendly manufacturing method that minimizes material waste by reducing excess scrap, contributing to more sustainable production practices

LightSpeed Lab Rapid Prototyping

Our Lightspeed Lab accelerates your project’s path from concept to reality. Using advanced laser systems and precision engineering, we deliver high quality laser cut tubing prototypes in a matter of days, enabling you to quickly evaluate designs, refine features, and move forward with confidence.

AGILE Product Development

Our AGILE Product Development team provides comprehensive support from initial idea through commercialization. With cross functional collaboration and iterative design, we help you optimize laser cut tubing solutions for performance, manufacturability, and speed to market.

In Stock and Ready to Ship

Browse our online store for in stock laser cut tubing available in a range of sizes. All tubing is ready to ship, making it easy to get the precision components you need without delay.