We are experts in using laser welding to join metals with precision and low-heat input to create complex components and subassemblies for medical devices. Our deep process knowledge and state-of-the-art equipment allow us to solve complex manufacturing problems and perform laser welding at a micro-scale. In addition to our decades of in-house experience, we also invest significantly in R&D projects to continually advance our capabilities. Our Lightspeed Lab process experts can help you take advantage of our laser welding technology with industry-leading prototype solutions, design feedback, and manufacturing process development.

Laser Welding

Laser Welding Applications Include

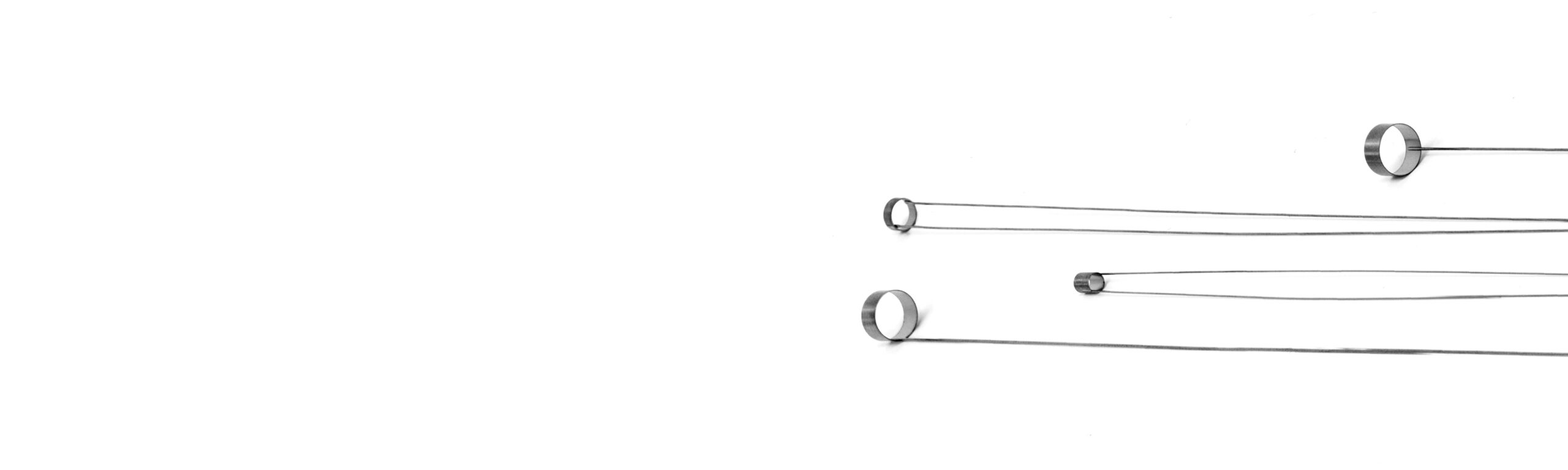

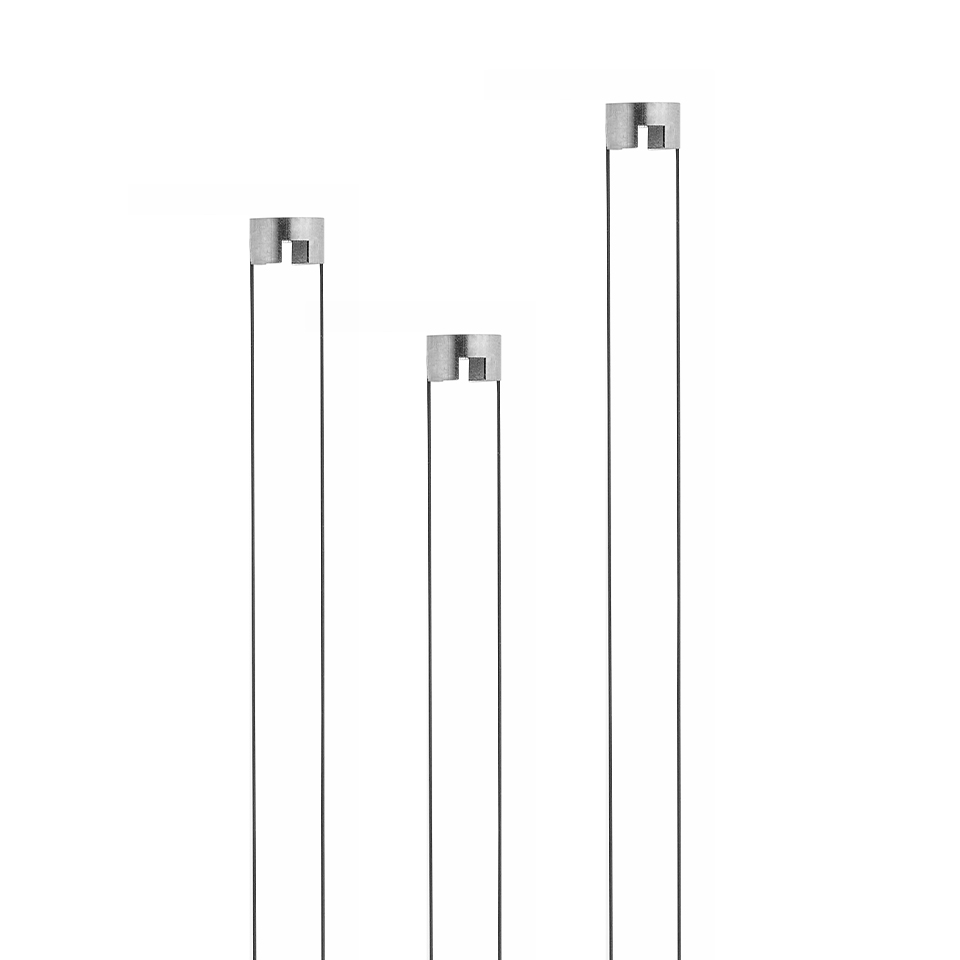

- Pull ring assemblies for steerable catheters

- Marker bands

- Flexible hypotubes

- 3D components

- Thin-wire delivery system components

- Hermetic seals for implants and instruments

- Micro implants

Laser Welding Specifications

min | max

- Material thickness: 0.025 mm | 1 mm

- Joint width limitations: N/A | 0.125 mm max gap

- Depth of penetration maximum: N/A | 1 mm

- Strength maximum: N/A | 80% of base material

Laser Welding Materials

We perform laser welding on a variety of metals, including, but not limited to:

- Stainless steel

- Nitinol

- Cobalt chrome

- Titanium

- Precious metals

Knowledge Center