Medical applications demand the exceptional properties of nitinol alloys and intricate, precision manufacturing techniques. We honed our competency in nitinol metallurgy, positioning Resonetics® as the ideal partner for developing mill products, semi-finished raw materials, and finished devices and components. We push the boundaries of nitinol technology, offering innovative solutions that empower our partners to achieve new heights of performance and precision.

Nitinol Material

Melt & Mill Product

We produce nitinol at commercial volumes and melt novel shape-memory and superelastic alloys, from binary to complex compositions with elements like Co, Cr, Cu, Fe, and Pt, engineered for precise thermo-mechanical performance.

Nitinol Wire

Our nitinol wire supports the most complex component designs requiring intricate geometric shapes. Through precise adjustments in the wire’s chemical composition and thermos-mechanical processing, Resonetics has achieved remarkable flexibility and kink resistance, making it indispensable for a wide range of medical device applications.

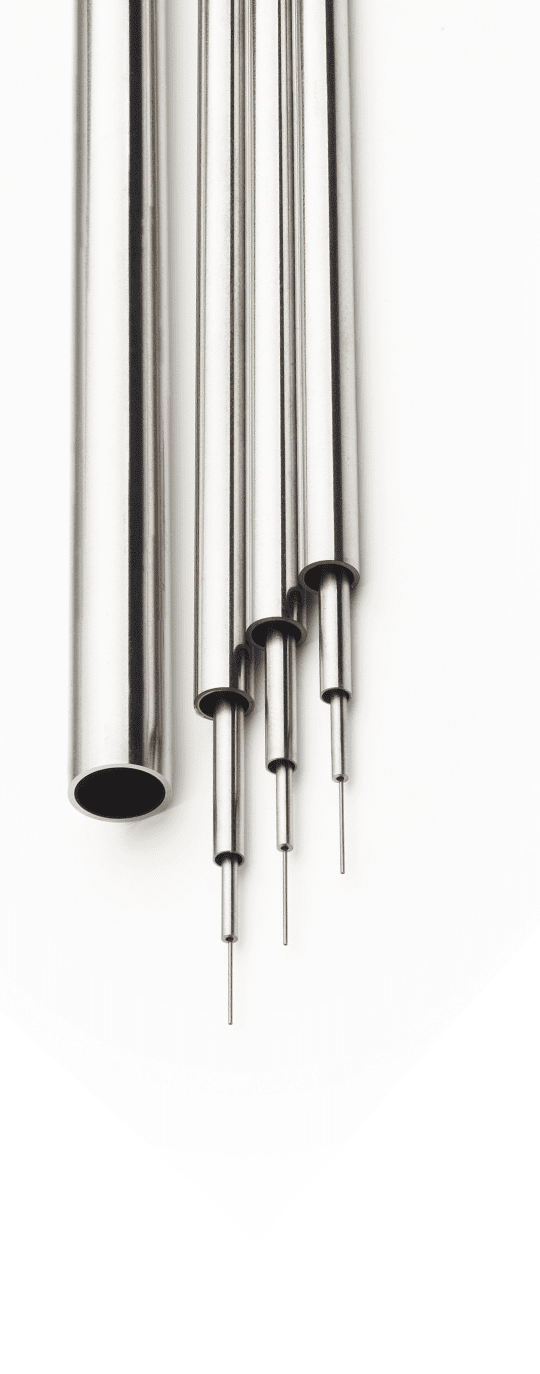

Nitinol Tube

We manufacture nitinol tubes of various sizes and finishes, ranging from hypotubes as small as a human hair to precision tubes as large as 12mm in diameter for stents, heart valves, and other implantable applications. We draw these tubes from our in-house melted nitinol bars, ensuring precise control throughout the manufacturing process.

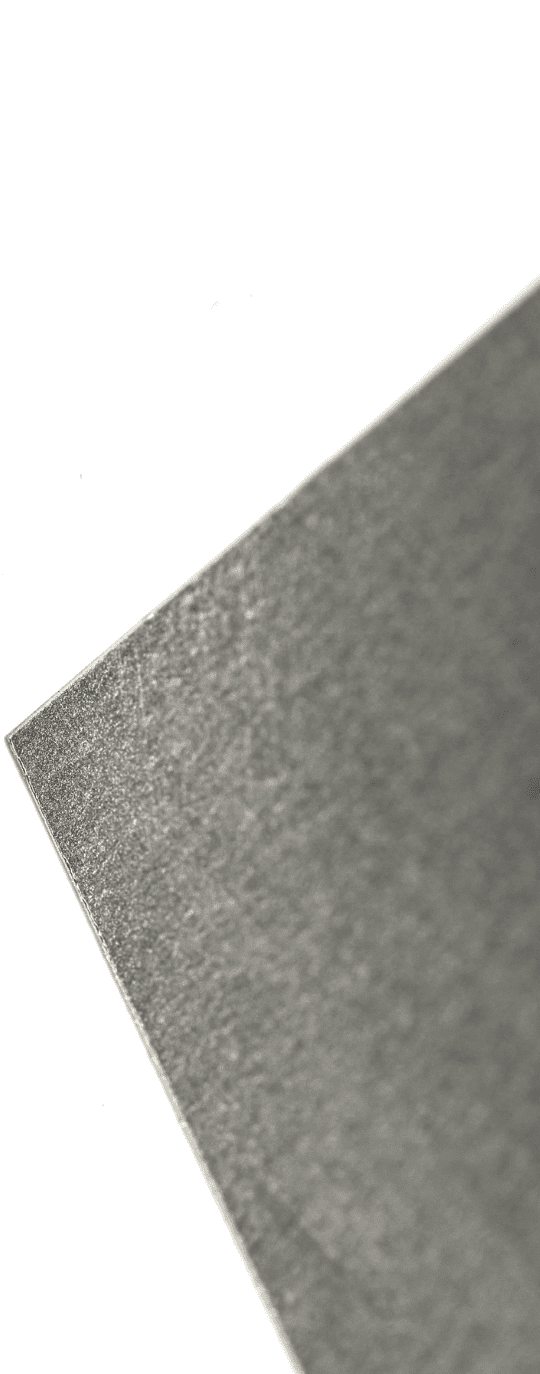

Nitinol Sheet

Nitinol in sheet form offers a flat substrate that facilitates the volume production of intricate 2-dimensional design components. This product format empowers designers to leverage high volume batch manufacturing processes to create expansive and unique structures that may be otherwise unattainable when using round nitinol wire or tube.