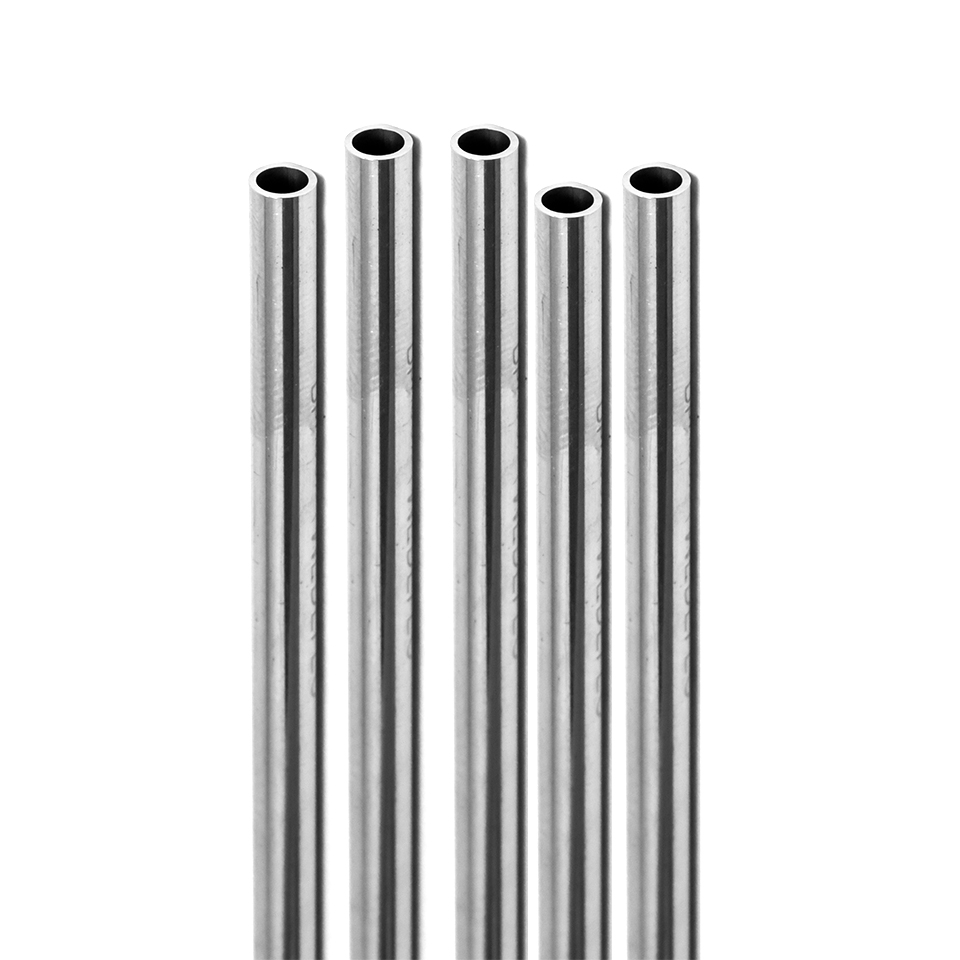

Our thin-wall stainless steel and precious metal tubing is the gold standard in the medical device industry. Since 1952, we have refined our cold-drawing process to lead the industry in the quality of the material surface finish and consistency of the wall thickness tolerance. Starting with a metal strip or seamless tube, we produce our thin-wall stainless steel tubing to the highest quality standards required for critical medical device applications.

Our small-diameter tubing is cold-drawn to size, resulting in precise finishes on the inside diameter (ID) and outside diameter (OD). Resonetics’ thin-wall tubing is then custom-made to your exact specifications. This helps ensure optimal performance and material integrity. Our proprietary cleaning process meets strict cleanliness standards for sensitive medical applications. With expanded capacity and a streamlined production process, we offer fast, reliable turnaround to help keep your project on track.