Knowledge Center

BLOG

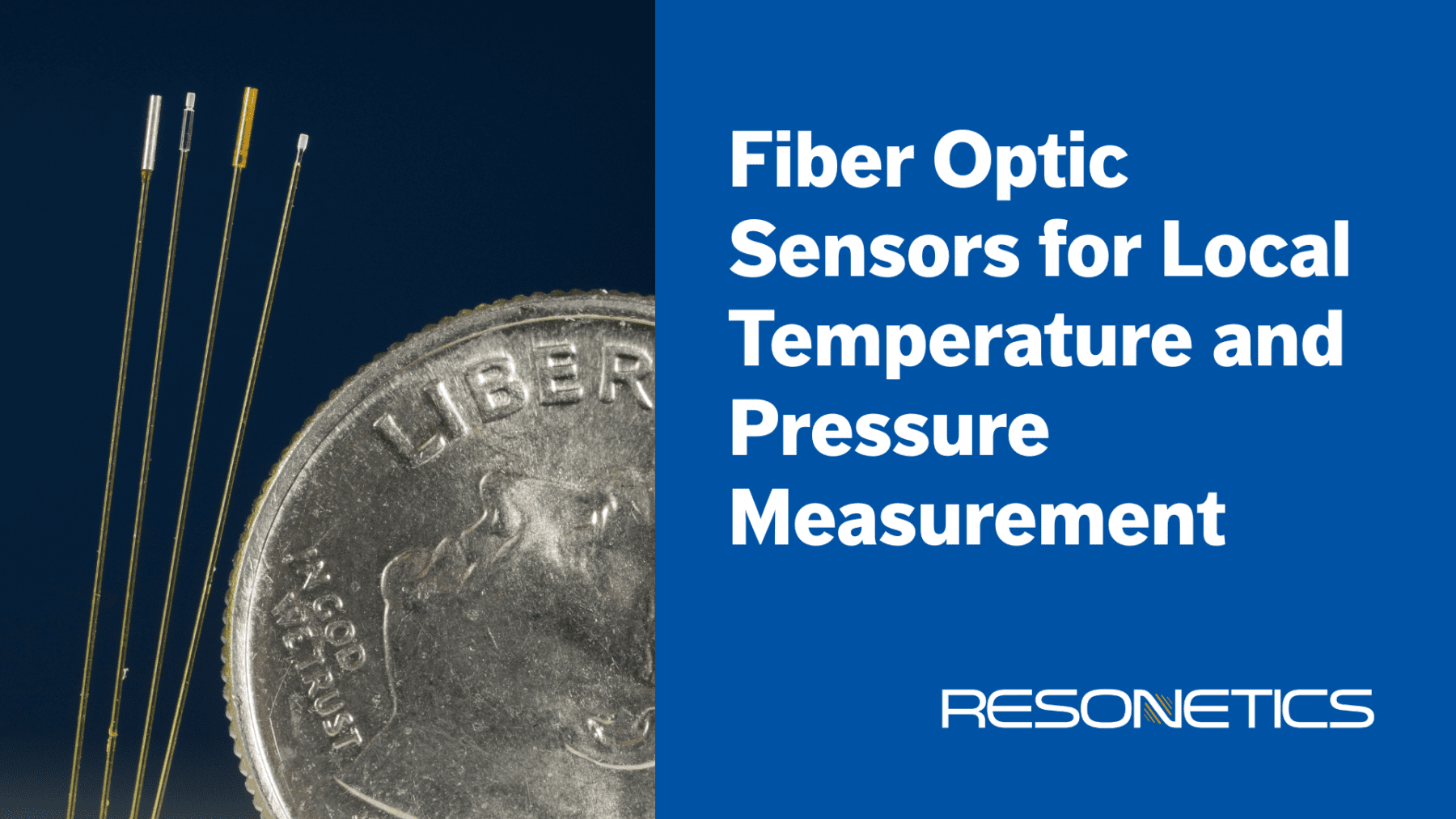

Fiber Optic Sensors for Local Temperature and Pressure Measurement: Setting the Standard for Reliable, Accurate Performance

BLOG

Fiber Optics 101: What to Know to Get Started

BLOG

Looking to Integrate Custom Fiber Optic Pressure Sensors into your Medical Device? Resonetics Supports You and Makes it Easy

BLOG

Navigating the Pressure Sensor Puzzle in Medical Device Development

BLOG

The Critical Need for Accuracy in Cardiovascular Pressure Measurement

ARTICLES

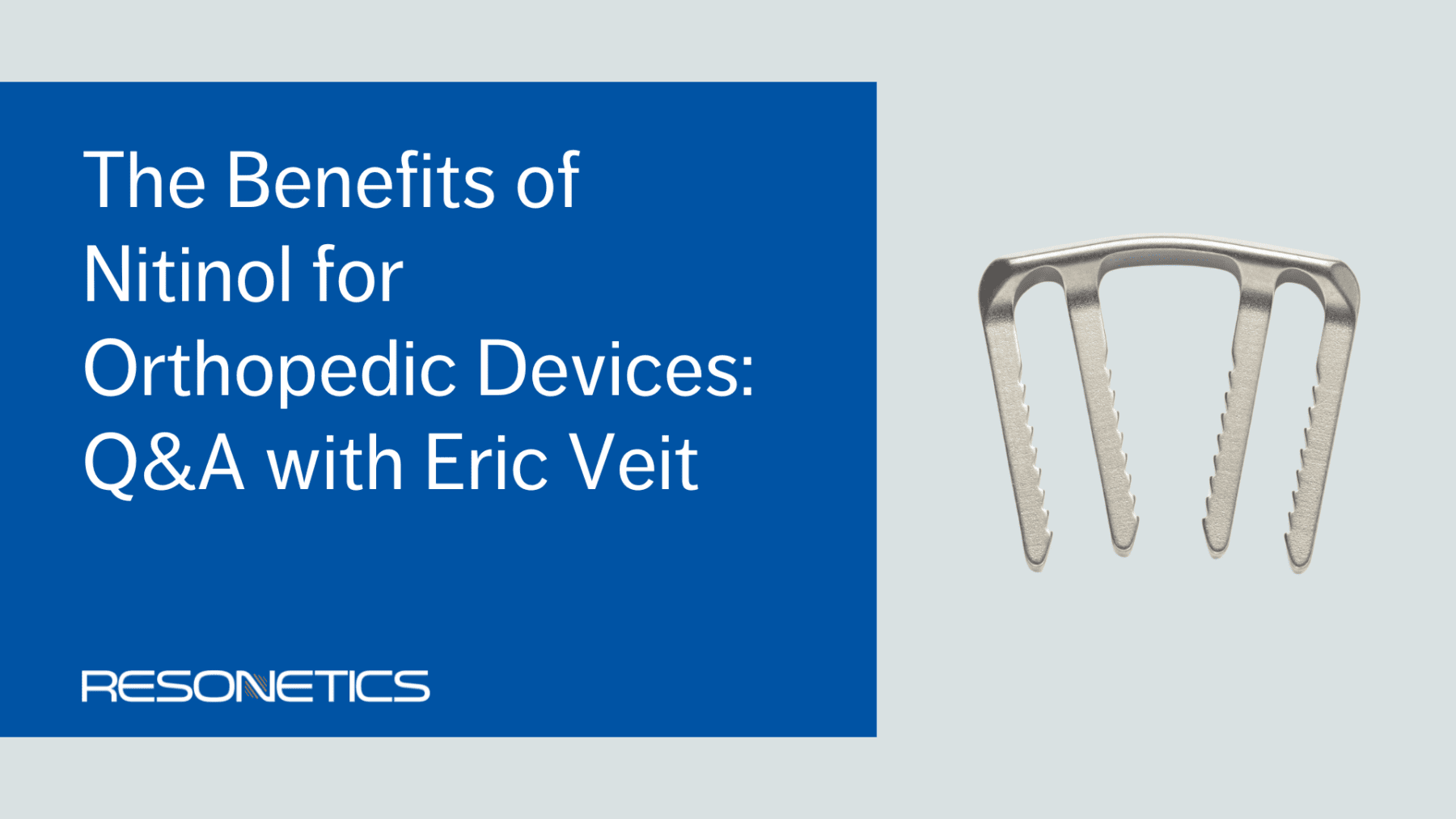

The Benefits of Nitinol for Orthopedic Devices: Q&A with Eric Veit

WHITEPAPERS

Nitinol Post-Shape-Setting TTT & TTS Properties

NEWS