The Resonetics Lightspeed Lab is a group of engineers and technicians deploying dedicated, state-of-the-art equipment to provide quick-turn prototyping solutions for the medical device and advanced diagnostic markets. Each Lightspeed Lab has technology expertise and develops manufacturing processes that can easily scale to high-volume production, which enables our customers to develop and launch products in record time.

About Laser Cut Tubing

When precision matters, lasers deliver what mechanical tools can’t: speed, accuracy, and zero physical contact. No sawing, no distortion, just clean geometry, even at the microscopic scale.

The result? Tubes with patterns, cuts, and features that mechanical tools can’t replicate. For medical applications such as advanced catheter components, our laser tube cutting machines enable better quality and performance.

Sizes and Tolerances

Resonetics offers laser cut tubing across a wide range of applications, from ultra-thin hypotubes to larger stainless steel profiles used in structural builds.

Wall thickness depends on the material, but cuts are typically performed up to 2 mm. Impressively, the process holds tolerances down to ±0.0005 inches, even on complex geometries and fine-scale designs.

Typical laser-beam width ranges between .001 to .002 inches. Resonetics utilizes both fiber and femtosecond laser cutters.

Shapes and Materials

Laser cut tubing begins with round, square, or rectangular profiles, while the end result can be processed into a multitude of geometries.

These tubes are transformed into components designed to meet tight specifications across a range of requirements. Materials include:

- Stainless steel

- Nitinol

- Titanium

- Select polymers

- And more

The material is selected not only for its properties, such as strength, flexibility, and biocompatibility, but also for how well it responds to laser cutting and provides an optimal end result for the MedTech device.

Experts in Laser Cut Tubing

Our proprietary tube cutting process is the fastest hypotube cutting solution in the industry. We have designed and built proprietary laser processing systems optimized for laser cutting metal hypotubes with high speed and precision. Partner with our experts to convert your functional catheter or component requirements into a laser cut pattern that will optimize your device performance and be cost-effective in volume manufacturing. Our team will speed up your development timeline with responsive design feedback, rapid quotes, and quick-turn prototype parts.

The Laser Cutting Process

Laser tube cutting uses a focused beam to carve patterns, holes, and shapes into metal tubing with unmatched precision.

Resonetics’ proprietary laser cutting process is a disruptive technology that offers new design options for advanced catheter delivery systems. Interventional devices such as flexible catheter shafts and delivery system components demand custom flexibility to navigate the vascular system. Laser cutting enables the optimized fabrication of hypotubes to match a device’s mechanical performance with the specific path it will travel through the anatomy.

The laser cut tubing Lightspeed Lab team works with your product development engineers to define the needs of your catheter delivery system, including critical functions like torque transfer, the radius of curvature, and tensile strength. We use this information to determine the right type of laser cut patterns that will enable the device’s functional performance.

Laser Cut Pattern Design Support

The laser cut tubing Lightspeed Lab team brings process expertise, custom laser cutting equipment, and proprietary software to enable your next complex catheter or delivery system. When recommending a laser cut pattern, we maximize manufacturing efficiency, ensuring you receive the most accurate prototypes as quickly as possible. Customers seeking an advanced catheter delivery system can combine various laser cut patterns (see below) with our stainless steel tubing for a smart alternative to conventional, complex braided catheter systems. We also offer complete catheter design assistance through our AGILE Product Development team.

Types of Laser Cuts

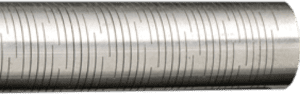

Interrupted Spiral Cut

Interrupted spiral cuts alternate between flexible and solid zones while maintaining a continuous tube structure. This design provides controlled bending and strong torque response, ideal for catheter shafts that need to flex and steer without losing strength.

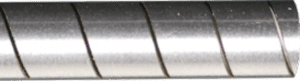

Spiral Cut

Spiral cuts create continuous flexibility along the entire length of the tube, making them ideal for devices that need to navigate tight or tortuous paths, such as delivery systems used in vascular access or neurovascular procedures.

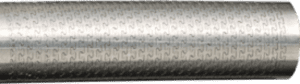

Puzzle Cut

Puzzle cuts use a repeating, interlocking pattern that lets two sections of tubing lock together. It’s a smart way to join dissimilar materials like nitinol and stainless steel, while keeping the joint flexible and inner lumen clear.

Working with the Lightspeed Lab

The primary goal of our Lightspeed Lab is to accelerate our customers’ product development cycle. This acceleration is accomplished via:

- Direct engineer-to-engineer engagement

- Sense of urgency

- Commitment to quality

We can solve the most difficult problems because we are committed to innovation and invest in R&D to develop next-generation manufacturing processes and equipment.