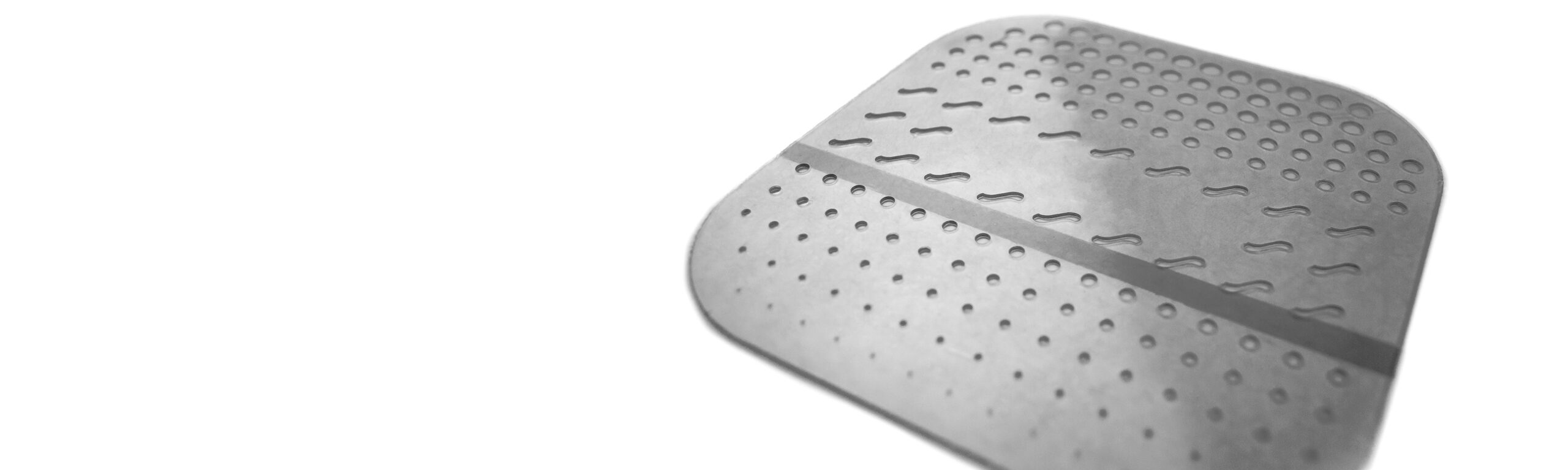

We perform high-density laser perforation on sheets, films, or plates to make tiny holes that increase the material’s breathability, wear time, and moisture vapor transmission rate. The advantage of laser perforation is that it maintains the integrity and strength of the material while leaving no working residue behind. It is used in various medical applications, including advanced wound care products, wearable biosensors, advanced diagnostics, and drug delivery devices.

Laser Perforation

Laser Perforation Process

High-density laser perforation involves using the energy from a laser to make tiny holes in sheets, films, or plates. The process begins with a laser that generates a pulse at a fixed repetition rate. Then a beamsplitter is used to convert the single laser beam into a controlled array of high-intensity beams that perforate the material with holes up to 5 microns in diameter. A rotating web carries the material set for perforation to specified locations for each laser pulse. As a result, high-density laser perforation offers precision cutting, high throughput, and accurate positioning. Unlike mechanically powered perforation techniques, no working residue is left on the material.

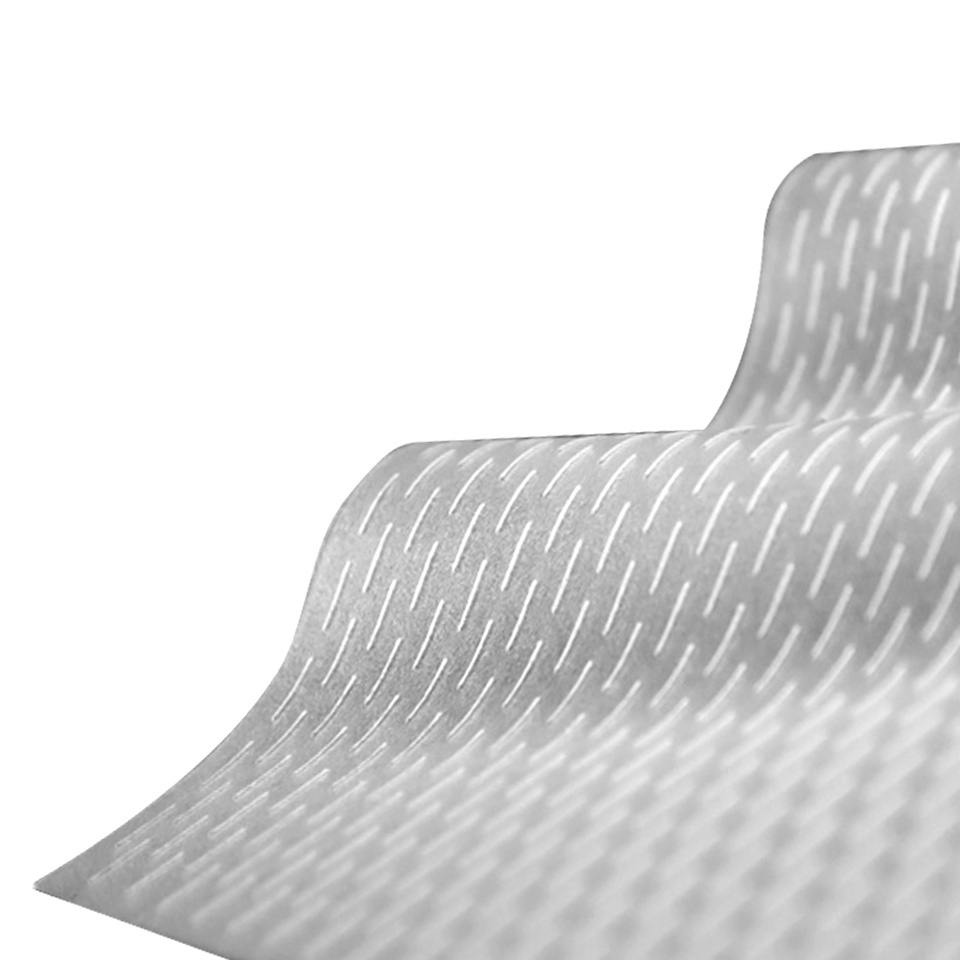

Laser Perforation Materials

Resonetics seamlessly integrates high-density laser perforation solutions into medical device manufacturing processes for all kinds of devices and technologies. We can produce a variety of shapes in unlimited patterns from an array of materials, including:

- Silicone pressure-sensitive adhesives

- Acrylic pressure-sensitive adhesives

- Polyester films

- Cotton, both dense and loosely woven

Medical Device & Technology Markets We Serve

Innovators developing groundbreaking medical devices rely on our laser drilling capabilities to create new technologies that advance treatment options and improve patient lives. Market applications for components and products produced with our laser perforation processes include:

- Advanced wound care

- Wearable biosensors

- Microfluidics

- Advanced diagnostics