We are the leader in laser processing for complex medical devices, components, and implants. Our engineers have deep process knowledge, and we custom-build our own laser processing systems to provide the best manufacturing solution for each application. The process experts in our LightSpeed Lab can help you take advantage of these advanced technologies with industry-leading prototype solutions, design feedback, and manufacturing process development.

Laser Processing

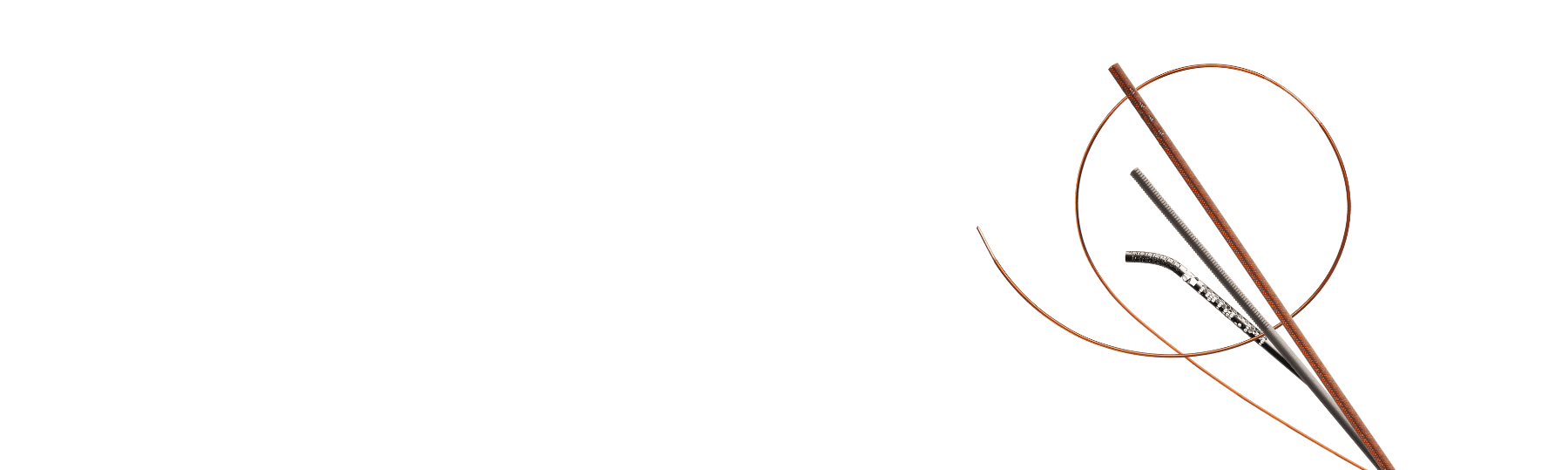

Laser Ablating

We have developed proprietary processes that use high-speed lasers to selectively remove material from a substrate or to machine components directly from solid metal. ASSURE Endpoint Detection monitors material removal during wire stripping, while 3D laser machining enables the production of micro-scale components and devices.

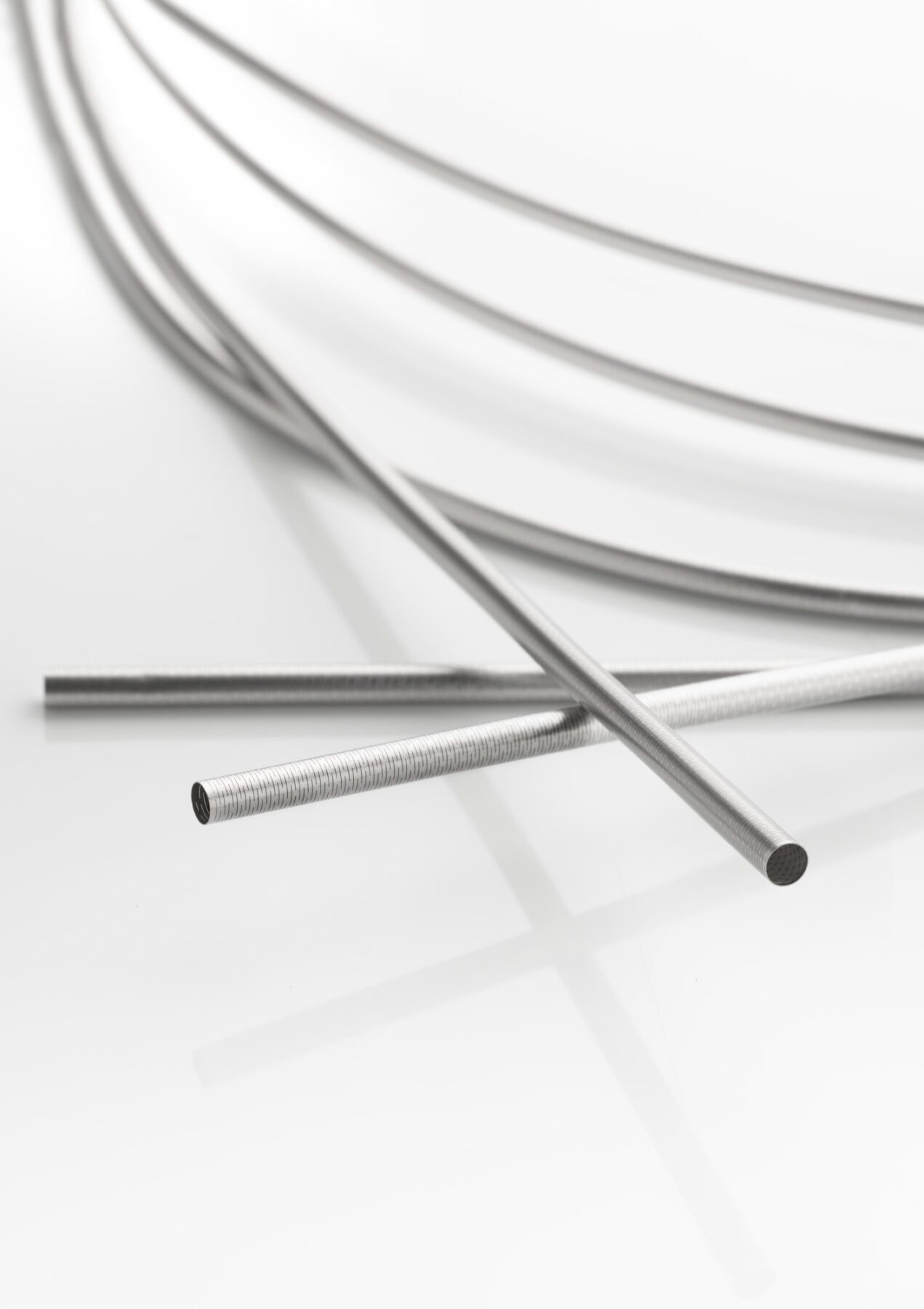

Laser Cutting

We laser cut complex MedTech devices and components from metals and polymers with industry-leading speed and precision.

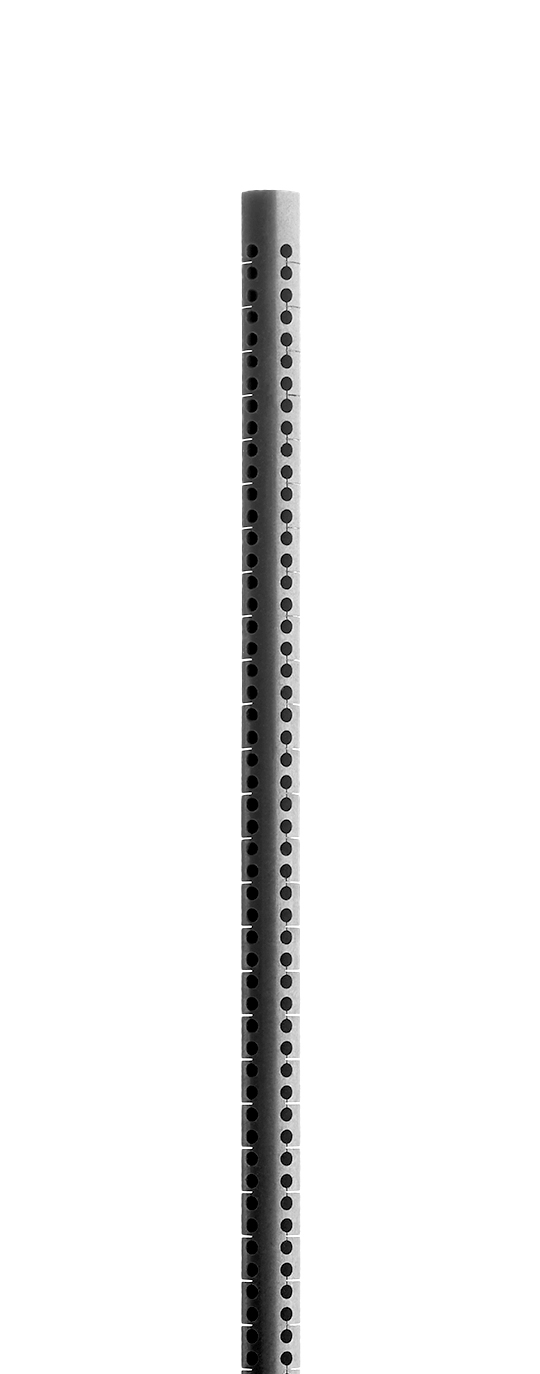

Laser Drilling and Perforation

We laser drill microscale holes and perform high-density perforation on sheets, films, or plates to improve breathability, extend wear time, and increase moisture vapor transmission, all while preserving the strength of the material.

Laser Welding

We use lasers to weld two metals together with low heat input and high precision to assemble the most complex micro-delivery system components.

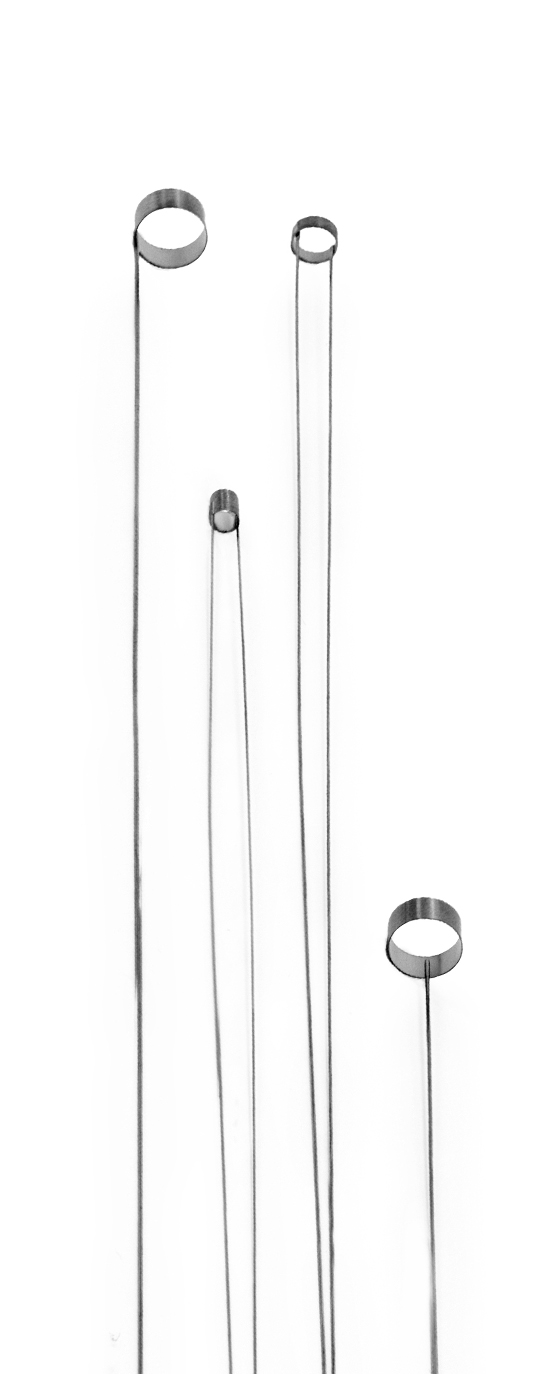

Laser Cut Tubing

We provide laser cut tubing with tight tolerances, delivering complex geometries and fine features for advanced medical device designs. Using both fiber and femtosecond lasers, we offer a variety of cut patterns including interrupted spiral, spiral, and dogbone to achieve controlled flexibility, torque response, and directional control.