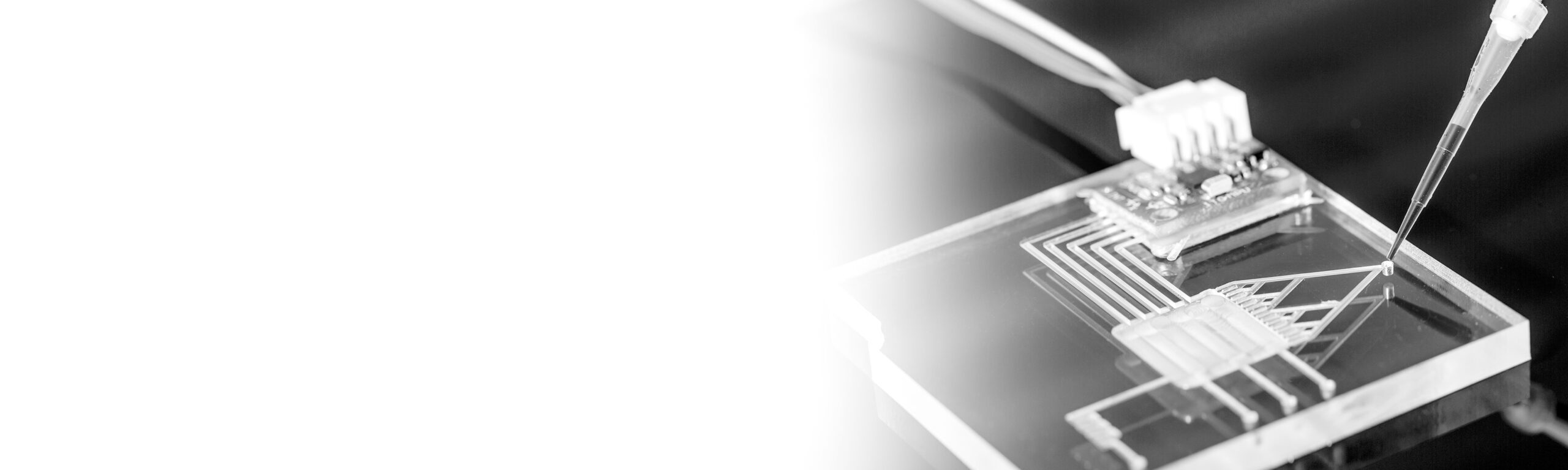

The Advanced Diagnostics market includes a range of diagnostics tests and devices that can detect diseases or measure different vital signs. These include in vitro diagnostics tests and lab-on-a-chip products that process a sample, such as blood or saliva and detect diseases or other conditions. Other devices in this market are biosensors worn on the body and can measure vital signs such as heart rate and blood pressure or glucose levels to manage diabetes. Early diagnosis of diseases and conditions is critical as the medical industry moves to more personalized healthcare and faster treatment. The advancement of microfluidic technology has helped point-of-care testing become faster, more portable, and more efficient to manufacture.

Diagnostics

Resonetics is a market leader in microfluidic laminate manufacturing used to make point-of-care and lab-on-a-chip devices. Our combined expertise in roll-to-roll laser processing, mechanical die cutting, automated stacking, lamination, and reagent handling allows us to produce complete microfluidic products. Our processes use highly automated equipment that can quickly scale up to high-volume production with limited tooling. This allows our processes to be fast and flexible, saving years in the time it takes to develop and commercialize a new device.

Diagnostic Manufacturing Capabilities

- Roll-to-roll laser processing

- Rotary and flatbed die cutting

- Multi-layer laminating

- Automated precision stacking

- Reagent and antibody placement

- High-density laser perforation

- Packaging

Diagnostic Applications

- Point-of-care testing

- Biosensors

- Continuous glucose monitoring

- Patient monitoring

- Molecular diagnostics

- Infectious disease testing

- Clinical chemistry

- Immunoassays

Knowledge Center