Resonetics® is a market leader in microfluidic laminate manufacturing used to make point-of-care diagnostics and Lab-on-a-chip devices. Using proprietary, custom-built equipment with a high degree of automation, we can rapidly scale from prototype to high-volume production. Our engineering team partners closely with customers to ensure each product meets the critical requirements of the application while remaining economically scalable. With highly repeatable processes, we maintain a standard tolerance of ±0.002 inch, delivering precision and consistency at scale.

Microfluidic Laminates

The Advantages of Microfluidic Laminate Processing

Our microfluidic laminate process is fast, flexible, and can quickly scale into high-volume production, saving up to a year in the time it takes to commercialize your device. Here are some of the benefits over conventional microfluidic manufacturing:

- Rapid and simple design changes

- Speed to production launch

- Significantly lower tooling cost

- Higher tolerance control and repeatability

Common Applications for Microfluidic and Lab-on-a-Chip Devices:

In Vitro Diagnostics (IVDs), microfluidic and Lab-on-a-chip products are commonly used for Point-of-Care (POC) Diagnostics. The advancement of microfluidic technology has helped POC testing devices become faster, more portable, and more economical to manufacture. This has become important as medicine and healthcare need accurate, portable diagnostics to move towards personalized healthcare and early diagnosis of diseases. Some of the applications for microfluidics devices and Lab-on-a-chip products include:

- Immunoassays

- Clinical Chemistry

- Molecular Diagnostics

- Whole Blood Monitoring

- Infectious Disease Detection

- Electrolyte and Enzyme Analysis

- Glucose Monitoring

- Protein Separation

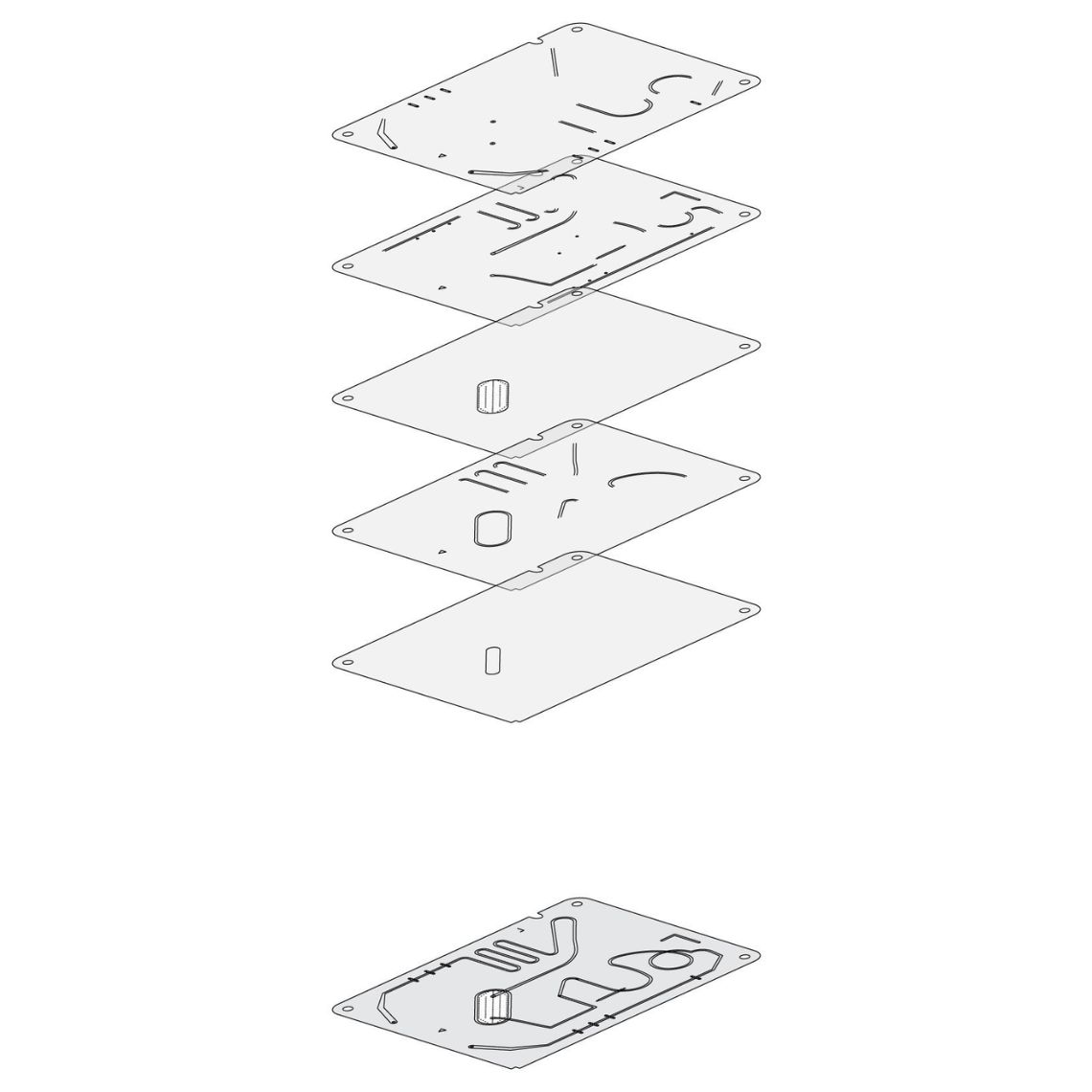

Automated Layering & Stacking

We manufacture microfluidic laminates by carefully aligning layers of thin films and adhesives with roll-to-roll laminating and robotic stacking to bond them together. The buildup of these layers creates sub-assemblies or the complete microfluidic device.

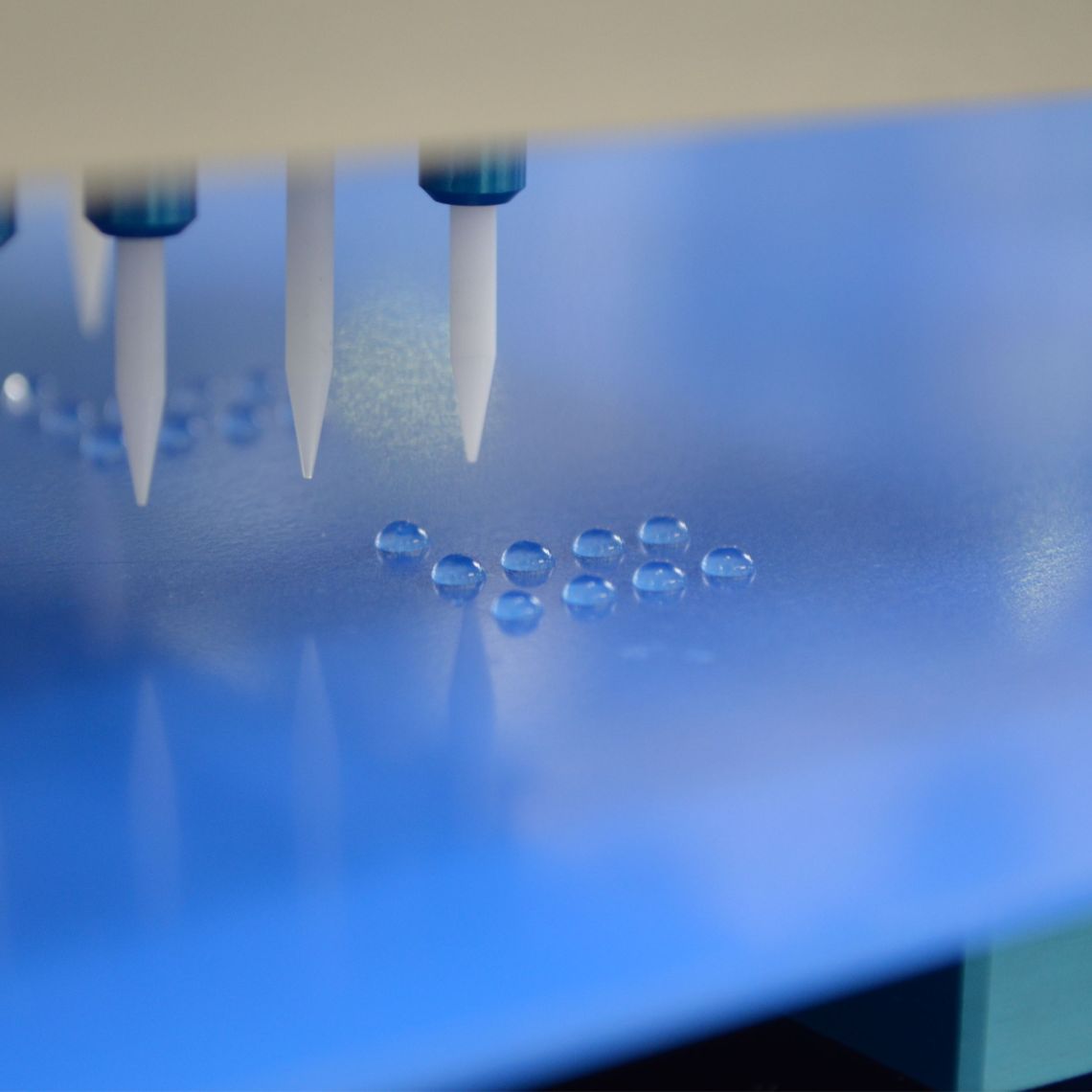

Reagent & Chemistry Handling

Our automated reagent placement and coating machines apply chemistries to microfluidic devices with high precision and throughput.

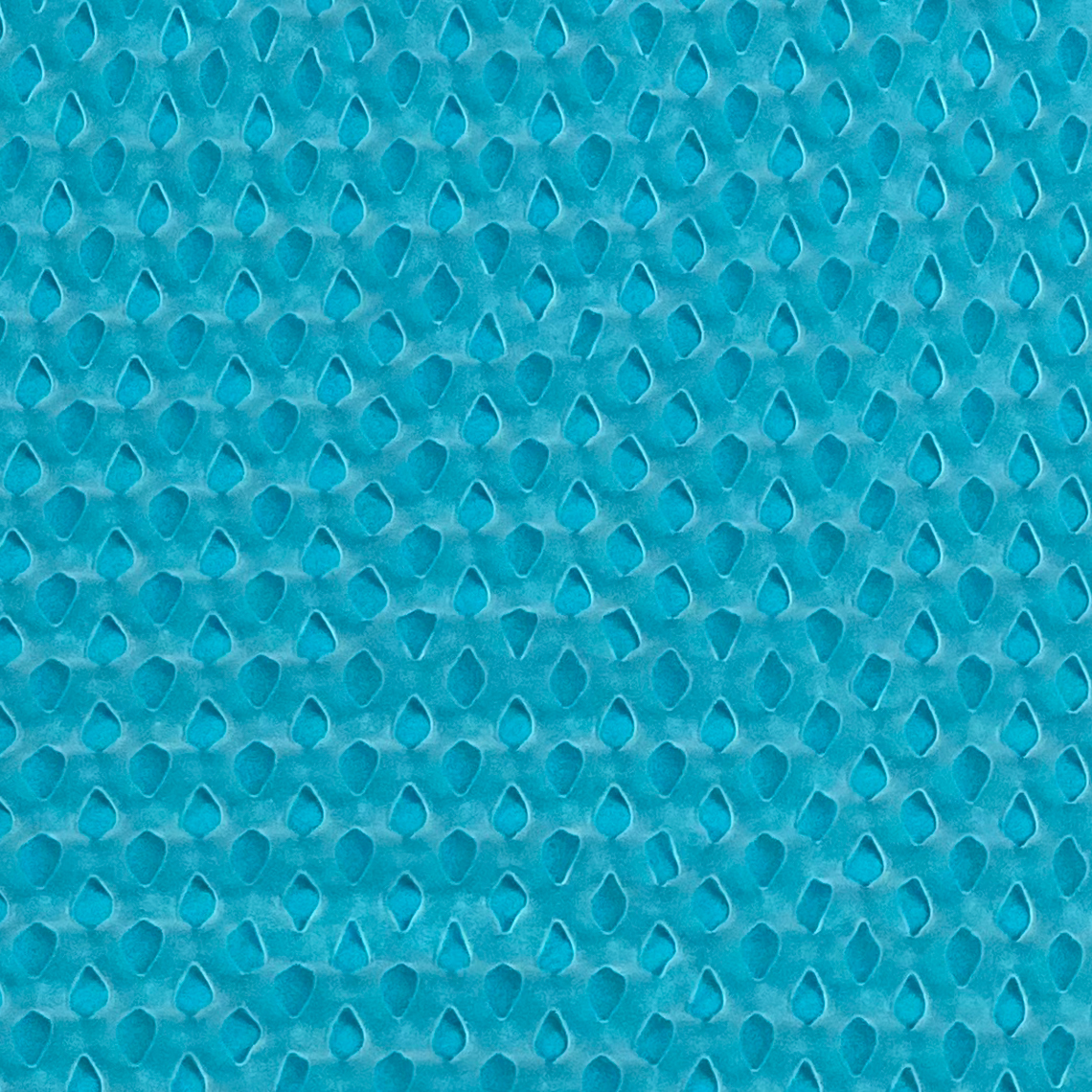

Roll-to-Roll Laser Cutting & Ablation

Our proprietary roll-to-roll laser systems cut and ablate microchannels in films, foils, adhesives, and tapes with speed and precision. These capabilities enable the formation of multilayer structures essential for microfluidic devices and other complex components.

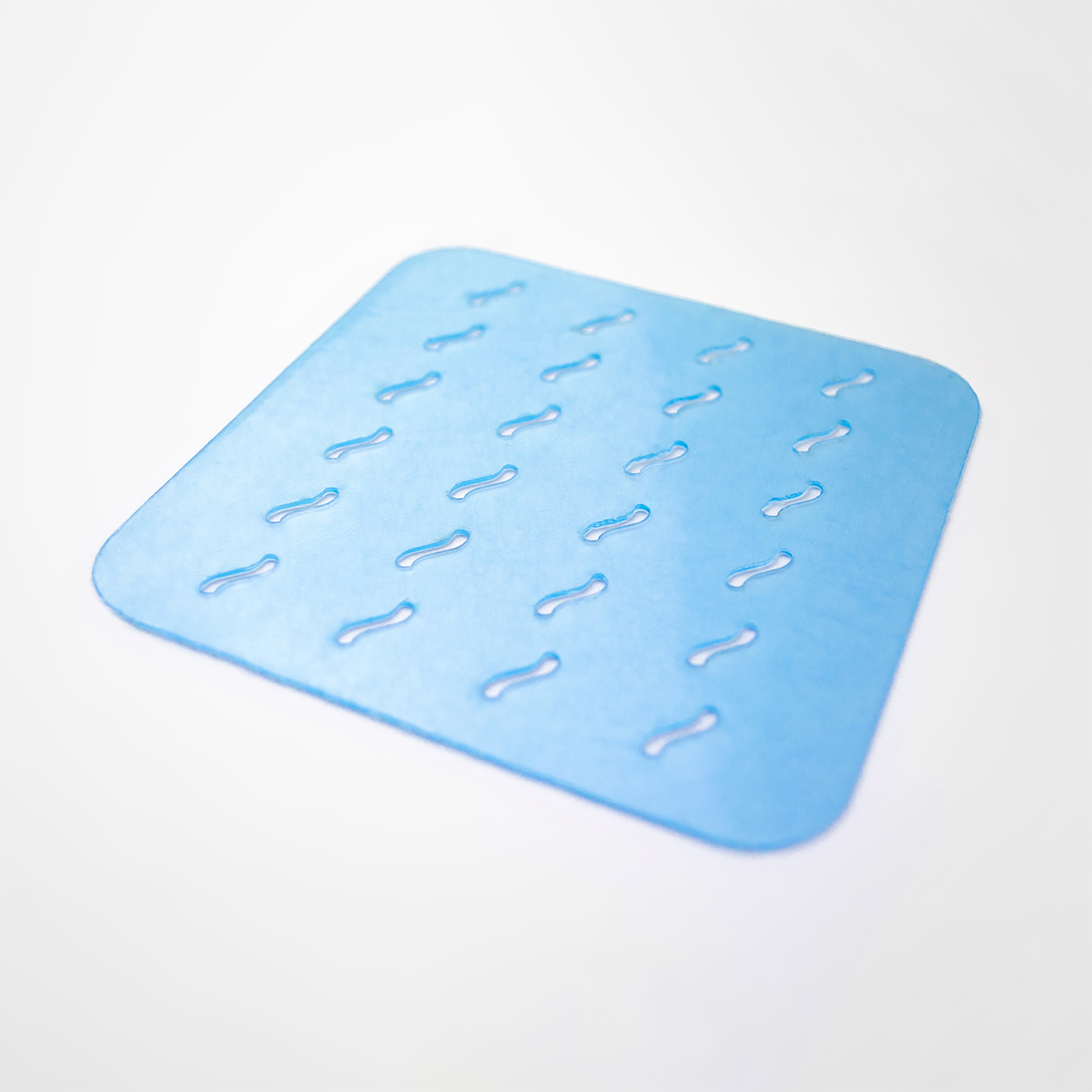

Rotary & Flatbed Die Cutting

We use rotary and flatbed die cutting to press and mechanically cut features into films, foils, adhesives, and tapes. These capabilities create the multiple layers used to build microfluidic devices or other components.

Key Markets

Innovators developing groundbreaking microfluidic testing devices rely on Resonetics to improve their time to market and quickly scale to high-throughput manufacturing. Applications for our microfluidic laminates include:

- Diagnostics

- Microfluidics

- Wearable Biosensors

- Advanced Wound Care