The AGILE product development team at Resonetics is driven by the guiding principles of quality, speed, and partnership. With deep expertise in catheter-based delivery systems, electrophysiology, cryotherapy, and implants. Our dedicated team of engineers will work collaboratively with you to bring elegant and disruptive medical solutions to life, from initial design and prototyping to validation and commercial scale-up.

AGILE Product Development

Complete Medical Product Development Services

Our diverse technical experience and rapid-turn mindset will provide a creative force to drive the development of your next therapy. Our engineers are well-versed in ISO 13485 Design Control and ISO 14971 Risk Mitigation practices. We support your team while addressing engineering and manufacturing challenges at all phases of development.

Our goal is to collaborate seamlessly with your team while striving to be flexible and attentive to the changing demands of your project. As your full-service partner, we can prepare the design documentation your project needs for regulatory approval and increase speed to market. Our AGILE Product Development team works directly with Lightspeed engineers to seamlessly integrate the latest advancements in processing capabilities and achieve a targeted, efficient, and scalable solution for your product. We consider manufacturability and unit cost upfront to ensure targets are realized at launch.

Product Design Services

- Medical device conceptual design and evaluations

- Complex part design (Solidworks)

- Complete catheter delivery systems

- Handle and mechanism design

- Nitinol implants and delivery system componentry

- Drawing package development and design documentation

- Product and component sourcing to find the best solution, utilizing both the broad manufacturing capabilities across the Resonetics network and external suppliers

- Structured phase-gate development process

- Manufacturing fixture design and documentation

- Complete assignment of product intellectual property

- Design verification, validation, and preproduction

- Initiate transfers from R&D to commercial production

- High-volume manufacturing

Medical Device Development Services

- Minimally invasive therapeutic and diagnostic medical products for:

- Electrophysiology

- Structural heart

- Peripheral vascular

- Neurovascular

- Cryotherapy

- Drug delivery

- Interventional cardiology

- Interventional pulmonology

- Endoscopy / Gastroenterology

- Pain management

- Catheter-orientated manufacturing process development

- Supply chain selection, management, and technical oversight

- In-vivo study protocol development, execution, reporting

- Clinical site initiation, physician training, and case support

- In-vitro test method development and fixture fabrication

AGILE Product Development Process

- Concept feasibility and planning

- Development and design freeze

- Design verification and validation

- Clinical and pre-production

- Design transfer and commercial production

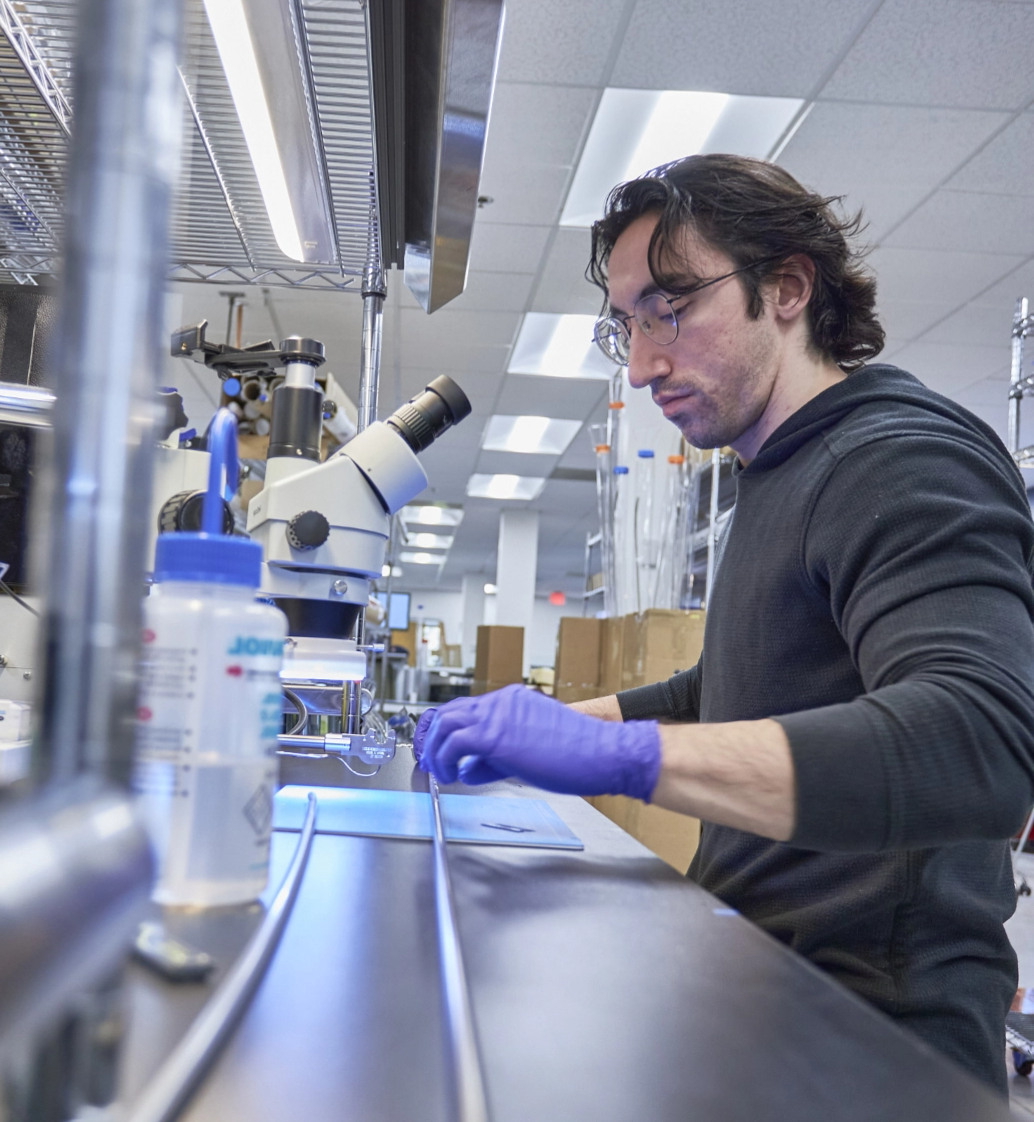

Dedicated Catheter Rapid Prototyping Lab

- Shaft lamination and complex catheter reflow operations (horizontal and vertical arrangements)

- Dedicated lab and laser welders for pull wire attachment and articulated systems

- Tipping stations and assorted secondary ops (skiving, hole punching, etc.)

- Overmoulding for custom hub and dilator tip configurations

- UV curing stations (metal halide and LED sources)

- 3D printing (SLA, FDM) and laser cutting for quick turn handle form evaluation, test fixture componentry, anatomical modeling, etc.

- Automated tensile/compressive test stand for bond strength analysis and trackability testing

- Assorted wet lab and vascular model performance testing capabilities