We are experts in using laser welding to join metals together with precision and low-heat input to create complex components and subassemblies for medical devices. Our deep process knowledge and state-of-the-art equipment allow us to solve complex manufacturing problems and perform laser welding at a micro-scale. In addition to our decades of in-house experience, we also invest significantly in R&D projects to continually advance our capabilities. Our Lightspeed Lab process experts can help you take advantage of our laser welding technology with industry-leading prototype solutions, design feedback, and manufacturing process development. When your design is ready for production, we have a standardized system to validate the process, experience, and resources to scale quickly to meet your production demands.

Laser Welding

Laser Welding Applications

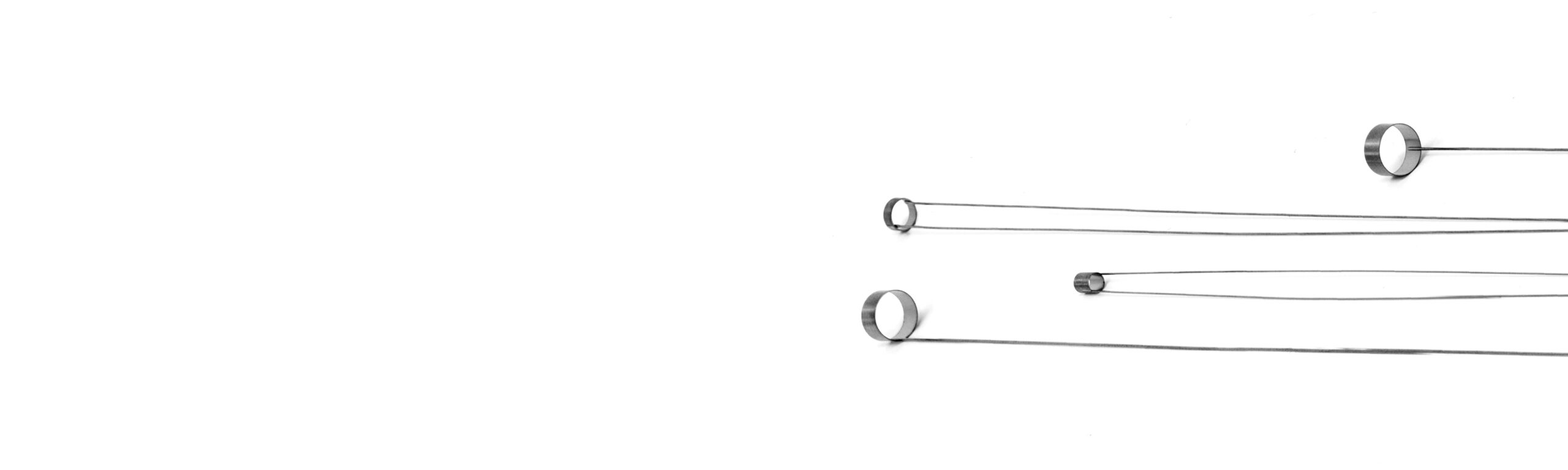

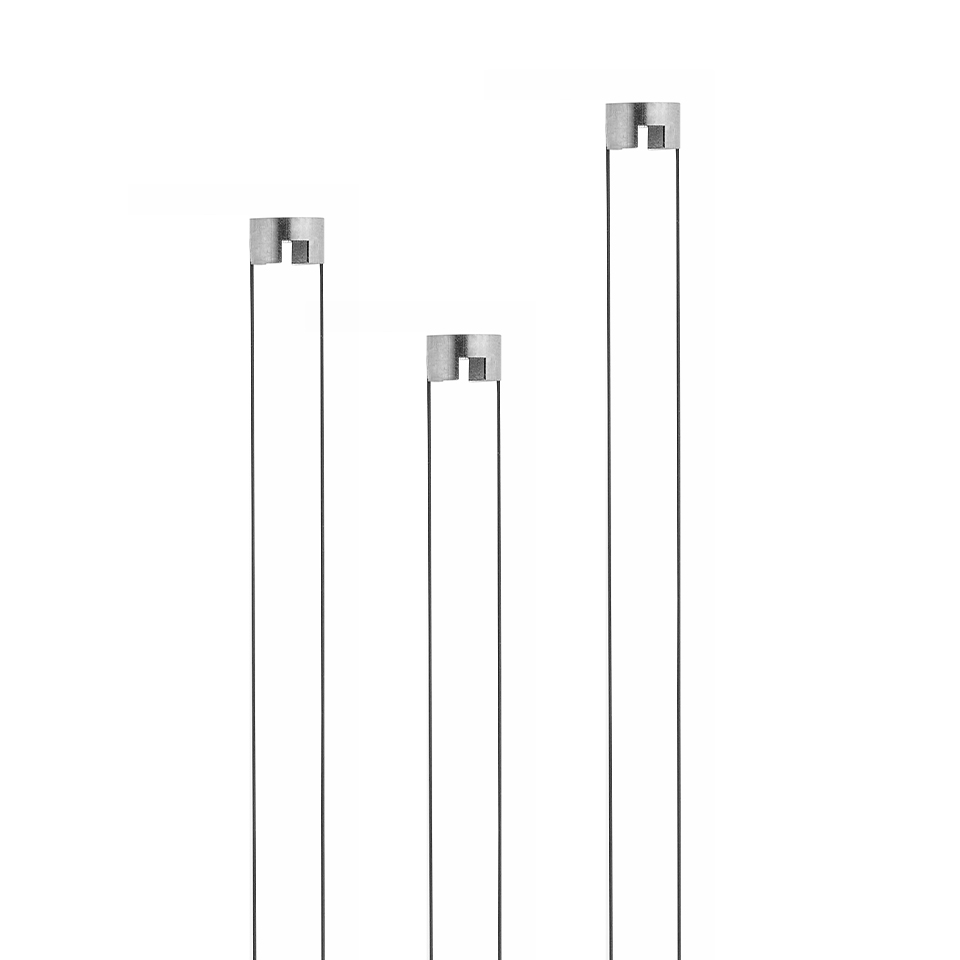

- Pull ring assemblies for steerable catheters

- Marker bands

- Flexible hypotubes

- 3D components

- Thin-wire delivery system components

- Hermetic seals for implants and instruments

- Micro implants

Laser Welding Specifications

min | max

- Material thickness 0.05 mm | 0.5 mm

- Joint width limitations N/A | 0.005 in max gap

- Depth of penetration maximum N/A | 0.040 in

- Strength maximum N/A | 80% of base material

Laser Welding Materials

We perform laser welding on a variety of materials, including:

- Stainless Steel

- Nitinol

- Cobalt chrome

- Platinum iridium

- Platinum

Medical Device & Technology Markets We Serve

Innovators developing groundbreaking medical devices rely on our laser welding capabilities to create new technologies that advance treatment options and improve patient lives. Market applications for components and devices produced with our laser welding processes include:

- Neurovascular

- Ophthalmic

- Structural heart

- Diabetes

- Electrophysiology

- Peripheral vascular

- Minimally invasive surgery

- Neuromodulation

- Sports medicine

Knowledge Center