The Resonetics Lightspeed Lab is a group of engineers and technicians deploying dedicated, state-of-the-art equipment to provide quick-turn prototyping solutions for the medical device and advanced diagnostic markets. Each Lightspeed Lab has technology expertise and develops manufacturing processes that can easily scale to high-volume production, which enables our customers to develop and launch products in record time.

Experts in Laser Ablation

Our laser ablation Lightspeed Lab teams have developed a multitude of proprietary processes that use laser ablation. ASSURE Endpoint Detection is a closed-loop process for laser stripping coatings from wires and tubes. MICRABLATE 3D Laser Machining is a next-generation micro-manufacturing process that enables the machining of micro-scale components. Our laser ablation experts can help you take advantage of both processes, plus a multitude of additional laser ablation capabilities to develop your next-generation medical device.

MICRABLATE 3D Laser Machining

The 3D Laser Machining team thrives on challenges involving cutting-edge micro-scale components too small for CNC Swiss machining. This process is fully automated, which minimizes handling and includes in-process geometrical inspections, bringing life to previously unattainable part geometry and scale.

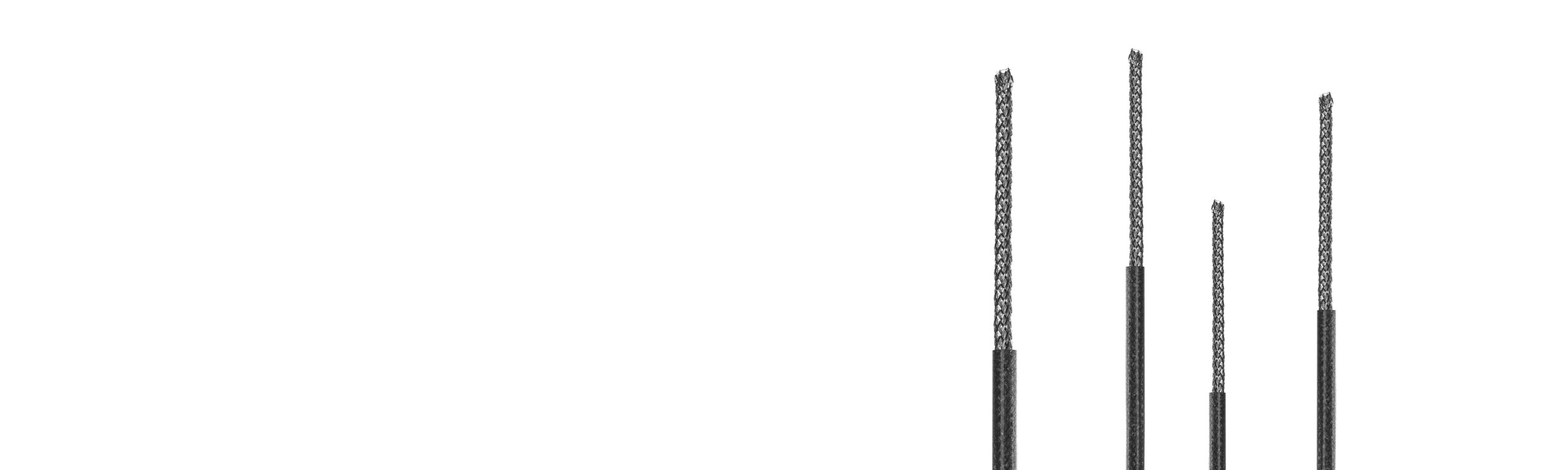

ASSURE Endpoint™ Detection

Our Laser Ablation Lightspeed Lab team developed ASSURE Endpoint™ Detection as an add-on to our custom reel-to-reel wire ablation platform to solve a common challenge of removing multi-layer eccentric coatings from wires. This patented process uses a closed-loop detector to adjust the laser ablation process in real-time, accommodating local inconsistencies in coating thickness. This allows our process to achieve a more consistent material removal, resulting in a more consistent finished component.

Working with the Lightspeed Lab

The primary goal of our Lightspeed Lab is to accelerate our customer’s product development cycle. This acceleration is accomplished via:

- Direct engineer-to-engineer engagement

- Sense of urgency

- Commitment to quality

We can solve the most difficult problems because we are committed to innovation and invest in R&D to develop next-generation manufacturing processes and equipment.