The Resonetics Lightspeed Lab is a group of engineers and technicians deploying dedicated, state-of-the-art equipment to provide quick-turn prototyping solutions for the medical device and advanced diagnostic markets. Each Lightspeed Lab has technology expertise and develops manufacturing processes that can easily scale to high-volume production, which enables our customers to develop and launch products in record time.

Experts in Nitinol Processing

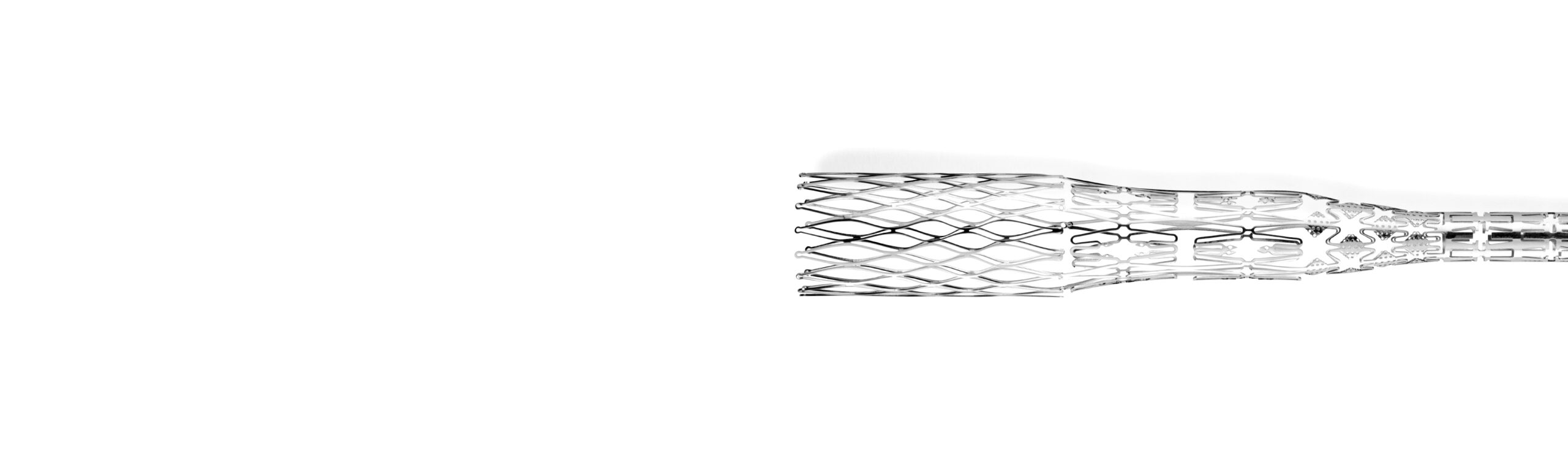

Our Nitinol Processing Lightspeed Lab teams are experts in different processing technology and how it affects the material properties that will be critical to the finished device. We specialize in ultrafast laser cutting, shape-setting, electropolishing, braiding, laser welding, centerless grinding, and precision machining of nitinol. The key to developing a successful nitinol device is understanding the application needs, material properties, and effects of the processing technology. Through open and responsive communication, our Lightspeed Lab teams will collaborate with your product development engineers to understand the critical performance needs of your project and develop the right manufacturing solution.

Our Nitinol Processing Lightspeed Lab teams are committed to driving the nitinol industry forward. We continually invest in internal R&D projects to expand our knowledge of nitinol processing technology and how it affects the nitinol material. We take this process knowledge and work with our internal equipment manufacturing group to develop the next generation of nitinol processing technology that will help our customers bring innovative medical devices to market.

Ultrafast Laser Cutting

The Nitinol Processing Lightspeed Lab teams use custom femtosecond laser cutting systems to cut nitinol without imparting thermal damage to the material. This lack of thermal damage ensures maximum part performance and minimizes downstream post-processing.

Shape Setting

Our Nitinol Processing Lightspeed Lab teams have developed custom automated salt bath systems that provide superior shape setting consistency. Our teams also have significant shape-setting tooling knowledge and multiple in-house resources to produce quick turn tooling.

Electropolishing

Our Nitinol Processing Lightspeed Lab teams have developed custom automated electropolishing equipment and utilize a scientific approach to process development, which provides better part quality and reliability.

Braiding

Our Nitinol Processing Lightspeed Lab teams have dedicated equipment to help customers quickly prototype and iterate different braiding designs. Combined with our other nitinol processing capabilities, we can provide unique manufacturing solutions.

Working with the Lightspeed Lab

The primary goal of our Lightspeed Lab is to accelerate our customer’s product development cycle. This acceleration is accomplished via:

- Direct engineer-to-engineer engagement

- Sense of urgency

- Commitment to quality

We can solve the most difficult problems because we are committed to innovation and invest in R&D to develop next-generation manufacturing processes and equipment.

Electrical Discharge Machining (EDM)

The Nitinol Processing Lightspeed Lab teams leverage electrical discharges or sparks to remove material to produce features in a part, performing wire and sinker EDM processing of nitinol to produce complex parts with tight tolerances.