We are the leading manufacturer of fiber optic sensors and readout units for the medical device industry. Our sensors are commonly used in applications where a clinician needs to gather data related to pressure, temperature, or force at the tip of a catheter during minimally invasive procedures. The sensors are highly-precise, extremely small, and impervious to radio frequencies, electromechanical interference, and microwave radiation. We have a standard line of fiber optic sensor products to enhance your device, or our experienced engineers can create a custom sensor for your specific application.

Fiber Optic Sensors

Benefits of Fiber Optic Sensors

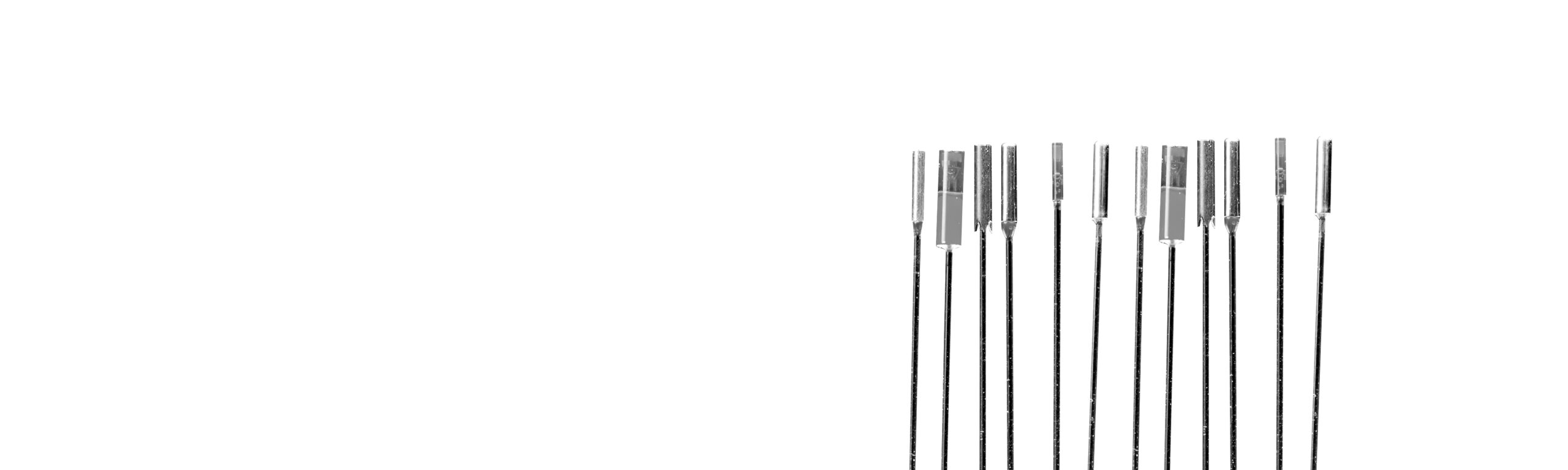

- Working length section diameters as small as 0.8 French

- Lead-in fiber diameter less than 0.5 French

- Exceptionally flexible glass fiber offers superior deliverability without kinking

- Front-looking configuration of sensor tips prevents side-facing/wall-bouncing measurement artifacts

- Lack of metallic components provides immunity to RF, MW, and MRI interference

Fiber Optic Sensor Technology

Our fiber optic sensors work by measuring the changes in the characteristics of light as it passes through a sensor. A readout unit transmits the light through an optical fiber to the sensing tip. The sensor contains a mirror that reflects the coded light to the readout unit, which analyzes the optical signal. The sensor contains features that change the properties of light based on outside parameters, such as changes in pressure, temperature, and force. Resonetics sensing technologies are independent of light loss, making them robust and reliable during therapy.

Fiber Optic Sensor Models

All of our fiber optic sensor models are actively used in various FDA and CE-approved medical devices and diagnostic equipment.

- FOP-M200: Features a 200-micron diameter and a standard range of ±300 mmHg relative to atmospheric pressure

- FOP-M260: Features a 260-micron diameter and a standard range of ± 300 mmHg relative to atmospheric pressure

- FOP-MIV: Assembled on a fully robotized manufacturing line and features a 550-micron diameter, a ± 300 mmHg range, and a 0-150 psi range

Fiber Optic Sensor Manufacturing Capabilities

- Design fiber optic sensors and readout units for the measurement of pressure, temperature, and force

- Multiple robotic sensor manufacturing and assembly lines for high-volume production

- Highly skilled engineering team with extensive experience developing FDA-approved devices

- In-house electronics, physics, chemistry, and optics experts

- Stringent quality assurance and regulatory compliance following industry best practices

- Partnerships with leading universities, institutes, and research centers

Knowledge Center