We are experts in solving complex manufacturing problems and have broad expertise in many different manufacturing methods for metal fabrication, including centerless grinding, CNC machining, photochemical machining, stamping, coiling, and microforming. Combined with our other capabilities, we can develop the best manufacturing process for your part and support your needs from prototyping to high-volume production. Each of our different capabilities in metal fabrication is supported by experienced process experts, state-of-the-art manufacturing equipment, and a proven quality system.

Metal Fabrication

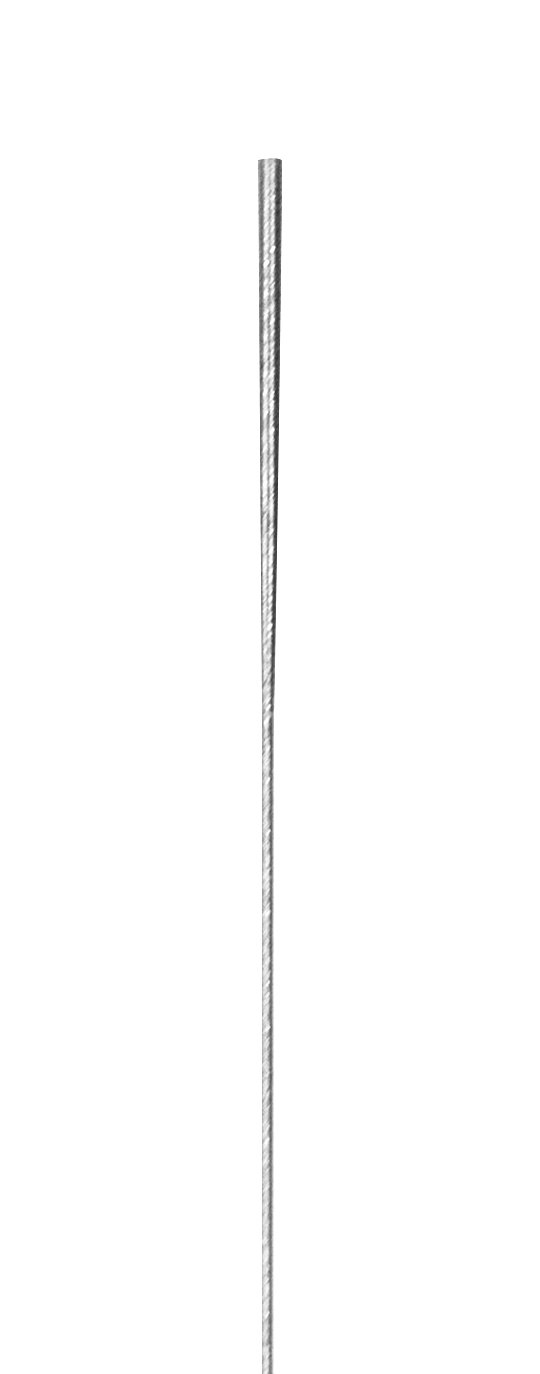

Centerless Grinding

We use our proprietary centerless grinding equipment to put features and profiles in metal wire for medical applications such as delivery systems for minimally invasive surgery and mandrels.

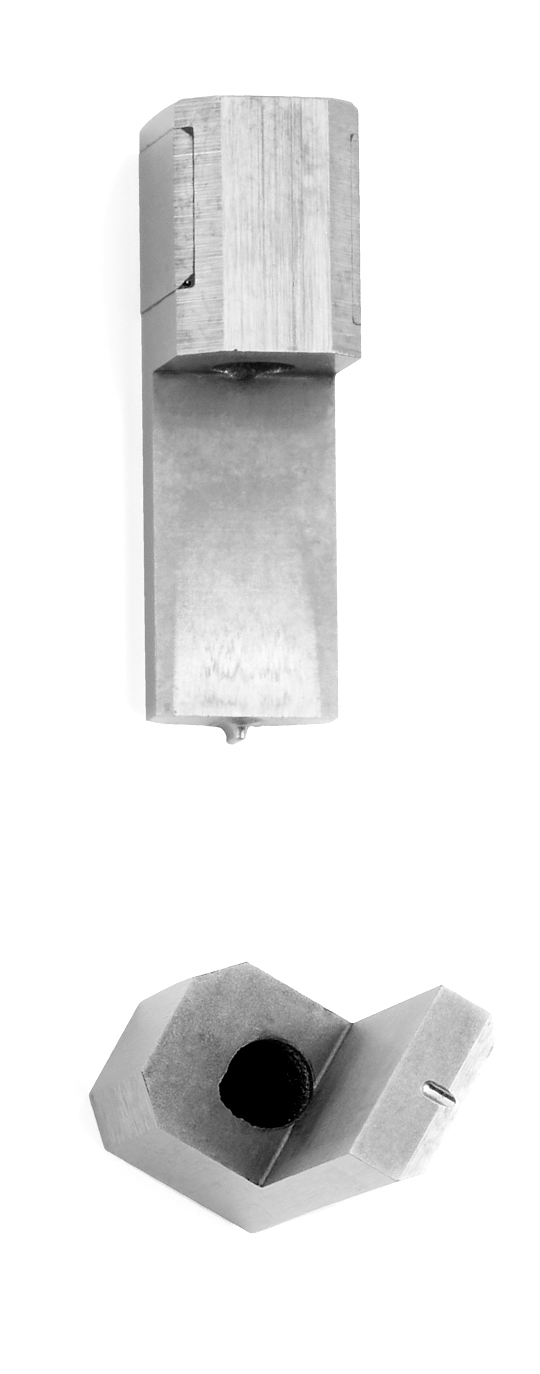

CNC Machining

Our experienced engineers and machinists can develop the best manufacturing process for your part while leveraging our comprehensive range of CNC capabilities, including Electro Discharge Machining (EDM), Swiss machining, turning, and multi-axis milling.

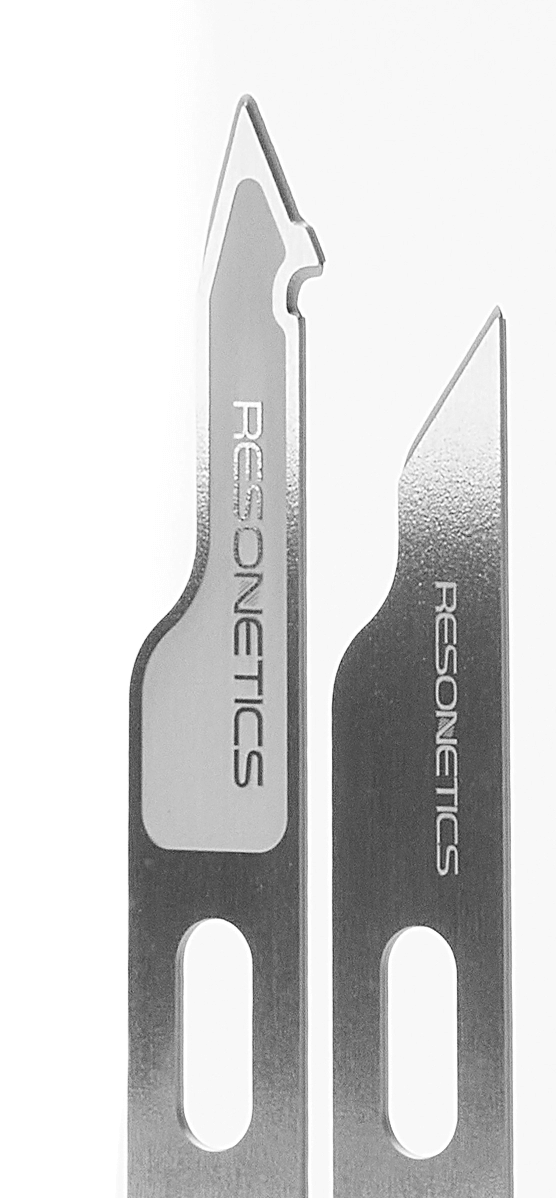

Photochemical Machining

We have decades of in-house photochemical machining expertise and proprietary processing equipment that allow us to produce parts with complex geometries and tight tolerances at high volumes.

Stamping, Coiling, & Microforming

Our capability to produce parts with complex shapes and tight tolerances with stamping, coiling, and microforming is supported by our deep process knowledge and in-house precision tooling center.