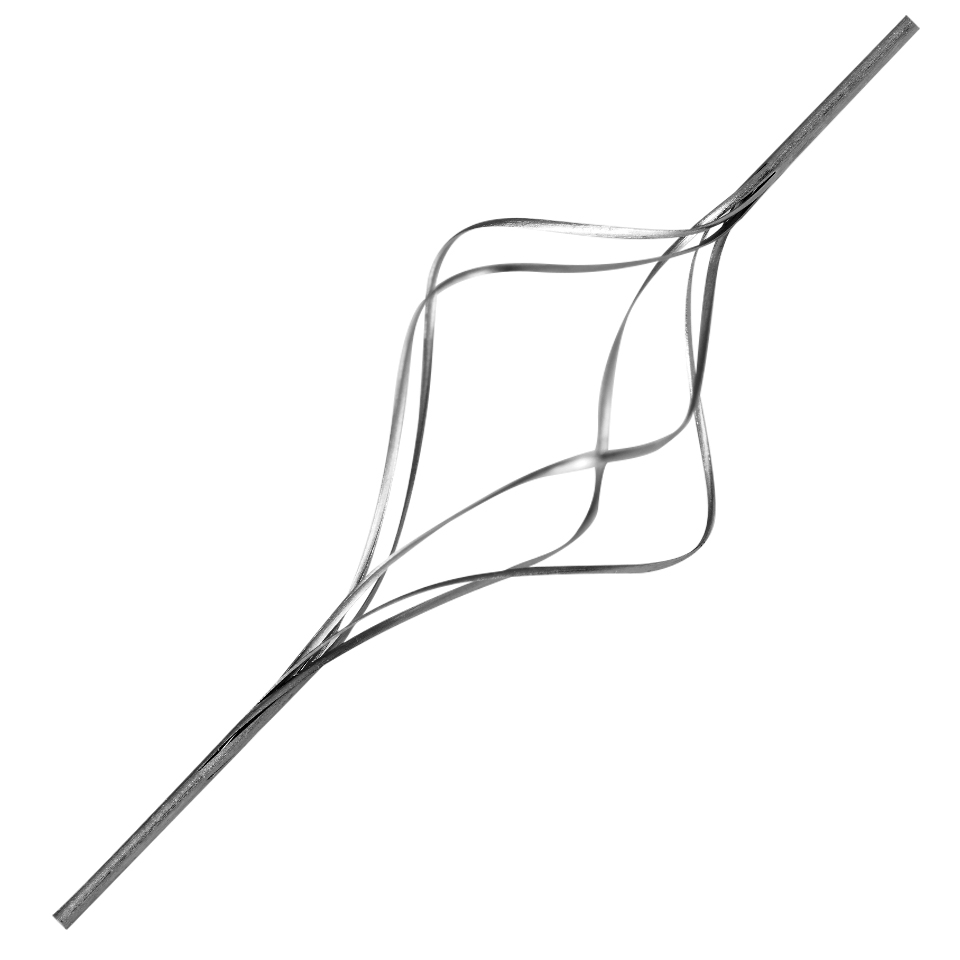

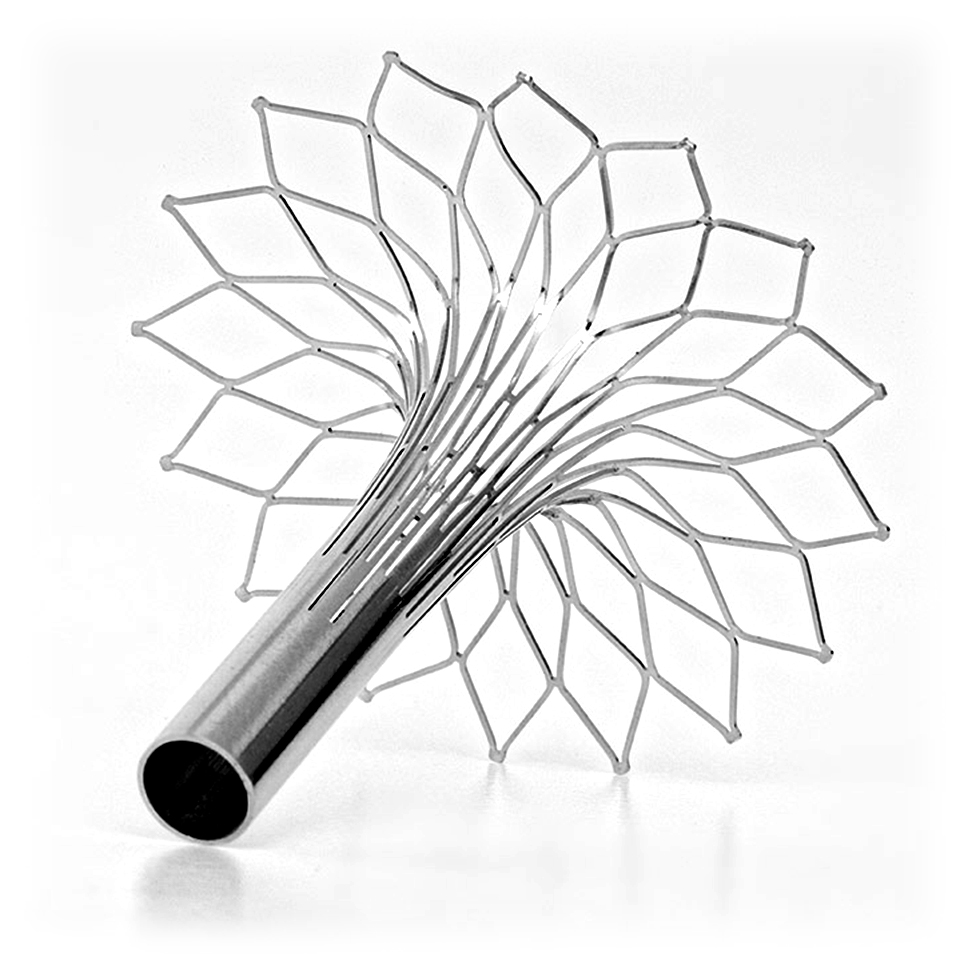

When shape setting nitinol, precise temperature control is essential, as heating the material to around 500-550°C enables it to achieve and retain its desired shape, ensuring optimal performance in various applications. This meticulous process guarantees the highest quality and reliability in nitinol-based products.

Nitinol shape setting allows medical device manufacturers to bring highly complex components to life for applications such as heart valve frames, stents, and delivery systems.

Our engineers understand the material properties of nitinol and work with our in-house precision tooling center to make fixtures to produce even the most complex nitinol shapes. We also develop and manufacture our own automated electropolishing equipment that allows us to maintain tight control of the processing parameters and have a stable and repeatable process.