Critical medical devices and implants require the highest quality raw material. We produce different types of raw materials for medtech applications, including precision thin wall hypotubing, precious metal marker bands, and nitinol wire. We produce all our raw materials to have high material quality, precise tolerances, and excellent surface finishes. We can produce our material to the exact specifications needed for your application and stock a wide range of standard sizes and shapes.

Raw Material

Precious Metal and Radiopaque Marker Bands

Our precious metal tubing is manufactured at the Resonetics Switzerland location and then processed into radiopaque marker bands. Precious metal marker band materials include platinum, platinum-iridium, and gold. We use a proprietary part production process that guarantees high precision and a burr-free finish. We produce custom marker bands to meet your exact specifications and standard parts that can be purchased through our online store.

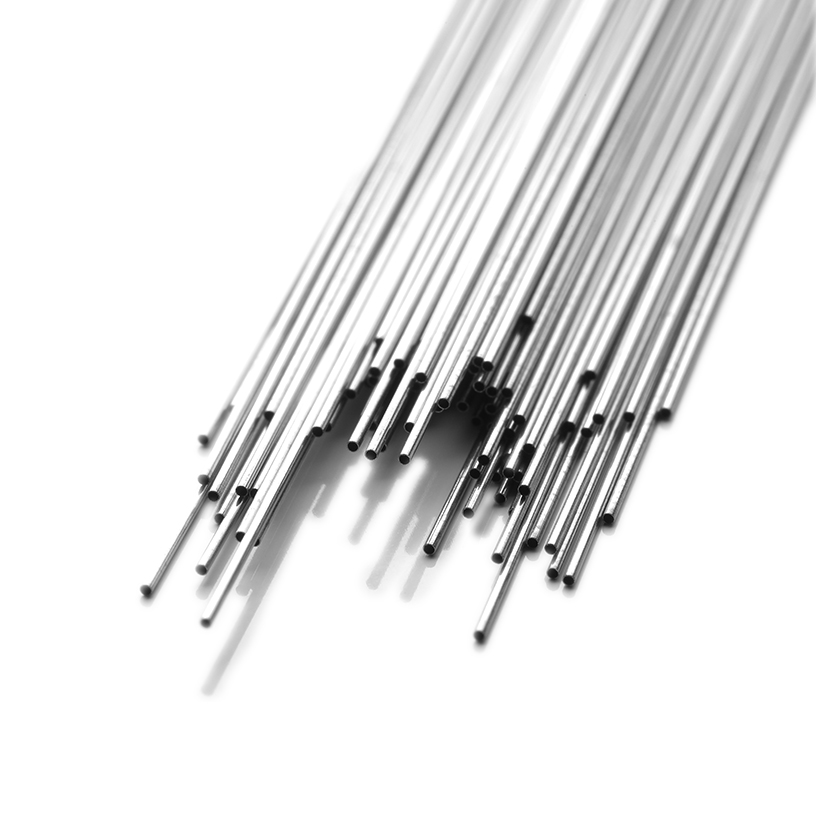

Thin-Wall Precision Hypotubes

Our MEDELEC stainless steel and precious metal hypotubing is the gold standard for tubing used in the medical device industry. Over the last 65 years, we have refined our cold drawing process to lead the industry in the quality of the material surface finish and consistency of the wall thickness tolerance. Starting with a metal strip or seamless tube, we produce our stainless steel and precious metal tubing with the highest quality for the most demanding medtech applications. Our small-diameter tubing is drawn to size, resulting in precise finishes on both the inside and outside diameters. Resonetics thin wall tubing is custom-made to your exact specification.

Nitinol Wire

Nitinol is a binary nickel-titanium alloy used in many critical medtech applications. The performance of the raw material is directly related to the level of control maintained throughout the production process. Our nitinol wire starts from the highest quality nitinol ingot and then is carefully drawn into the desired wire diameters. Through our partnership with Ingpuls Medical, we can produce nitinol wire that leads the industry in quality and precision.