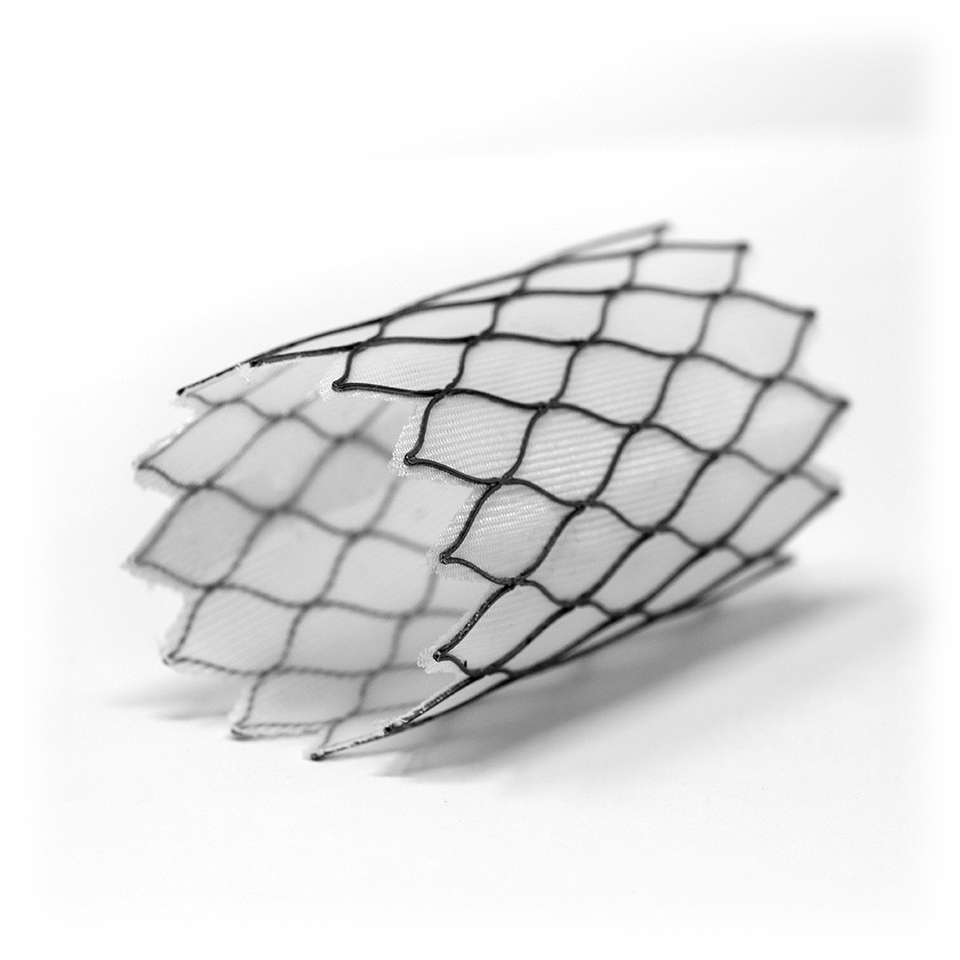

Our advanced sutureless lamination technology applies fabric and polymer covers to medical implants and devices in one layer, with no sutures, while maintaining good adhesion. The key to this capability is our proprietary adhesion process that improves the bond between metal and polymers. This allows the covering to be laminated onto the stent or scaffold without requiring manual suturing or multiple layers. These coverings can be porous or impermeable, and porosity may vary depending on the medical device’s requirements based on its function, target area, tissue ingrowth, etc. A key benefit of porous covers is that they allow communication between the blood and the blood vessel wall and enable tissue ingrowth to prevent stent migration from the target area. Sutureless lamination ePTFE and fabrics like Dacron feature porous structures and are ideal for covering medical devices such as structural heart devices or stent grafts for blood vessels larger than 10mm.

Resonetics specializes in ePTFE and fabric covering technologies for various medical devices such as stent grafts, heart occluders, heart valves, left atrial appendage devices, etc.