We use our proprietary centerless grinding equipment to put features and profiles in wires and tubes for medical applications such as delivery systems for minimally invasive surgery and mandrels. With unparalleled machine design, automation experience, and over 100 unique grinding systems, our engineers and technicians produce more than 6 million ground components annually.

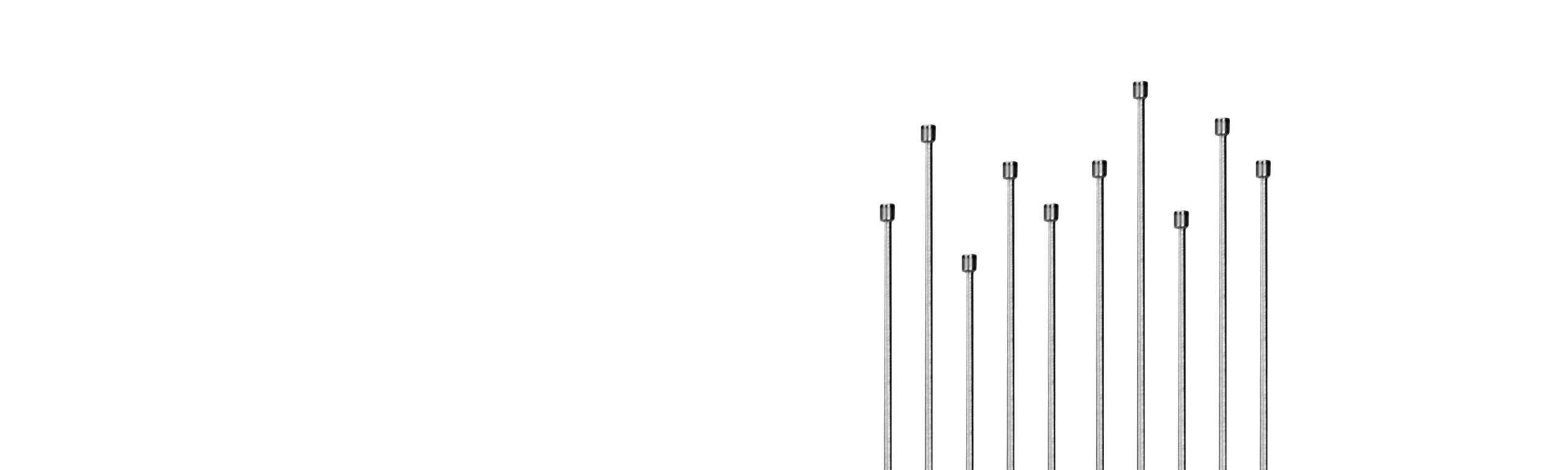

Centerless Grinding

Centerless Grinding Features

- Tapers: Single and multiple

- Steps: Single and multiple

- Types: Profile, centerless, and plunge grinding

Grinding Specifications

- Max OD (outside diameter):

- 1 inch for thrufeed grinding

- 0.25 inches for profile grinding

- Typical Tolerancing:

- OD (outside diameter): +/-0.0001 inches

- Grind Length: +/-0.005 inches

Centerless Grinding Materials

We perform centerless grinding on a variety of metals, including, but not limited to:

- Nitinol

- Stainless steel

- Titanium

Knowledge Center